Aluminum is extensively used in a wide array of constructions as window frames, shop fronts, roof superstructures for shopping centers, sidings, curtain walling, cast door handles, and staircases amongst other usages. Aluminum building products are particularly useful as they keep a building cool in summer and warm in winters. Stability, durability, and thermal efficiency are just some of the advantages that aluminum has over other metals to be used in construction.

With LEED ratings being of high precedence these days, making green buildings has become a major trend in the construction industry. One of the criteria for a good rating is the recyclability of the materials used. Aluminum has a very high recycle rate as it can be recycled almost indefinitely without any harm or reduction in its basic qualities. Even the energy required to melt used aluminum is lower – only 5% of the energy that is required to produce the primary metal.

All these factors make aluminum a highly popular metal to use in construction. There are several other advantages that aluminum has that make it a top choice as a construction material today.

Advantages over other metals

Aluminum has good resistance to corrosion and this not only gives the metal a long life but also reduces maintenance costs significantly. In fact, aluminum is seen virtually as a maintenance–free material in construction.Another significant advantage that aluminum has over other metals is its lightness. This means that it is not only easy to handle on site, but is also easy to form and join.

Aluminum is also seen as a strong and safe construction material. It does not burn and is hence classified as a non-combustible construction material. At very high temperatures aluminum alloys do melt, but this is seen as a good property as it opens the building to outside air and allows heat and smoke to escape. Also, aluminum panels do not release any harmful gases in case of fire. It is due to these advantages that thin aluminium cladding panels are increasingly being used in the construction of industrial roofs and external walls.

The metal has a high strength to weight ratio, making it a popular choice for facades and cladding of non-residential buildings. These not only add to the strength and durability of the building but also increase its energy efficiency and add to its insulation properties. Its strength combined with its light weight result in a low load on the supporting structures of buildings.

Varied applications

Roofing is another area where aluminum is used extensively. Stand seam aluminum roofing is a popular product. Being light weight, strong and durable, aluminum is seen as a good roofing material. Unlike other forms of roofing, like tiles, aluminum roofing does not require structural reinforcement. Its corrosion resistant property makes it a good roofing choice in coastal areas. As aluminum is more malleable, it allows for intricate and detailed designs making a strong and beautiful roof.

As already mentioned, aluminum is also used in doors, windows, stair railings, false ceilings, structural glazing, and even false flooring.

Compared to other metals (to go in a separate box)

Aluminum – Corrosion resistantCarbon steel – Self destructs over time due to continual conversion of the base metal to iron oxide

Stainless steel – Chromium in alloy mixture oxidizes on the surface of the metal, forming a thin transparent film.

Steel – Has to be painted adding to costs, also coatings may have to be periodically replaced

Aluminum – Elasticity is about one-third that of steel’s making it suitable only for stocky columns

Steel – Suitable for slender columns as well

There are several prominent buildings that have used aluminum as an integral part in the construction process.

Chrysler Building

The exterior of the building makes heavy use of aluminum.

Experience Music Project

21,000 shingles of aluminum and stainless steel make the exterior.

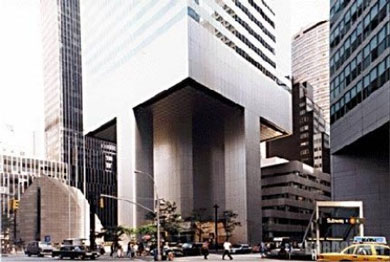

Citicorp Center

Aluminum and reflective glass were used as facing materials.