Recycled glass

Inference: Recycled glass has been innovatively used in the country for a long time now. So where is it now?

Though glass as a construction material in cladding and insulation applications has definitely come of age in the country, there is no really significant progress when it comes to recycled glass product innovations or applications. Recycled glass seems to be a phenomenon essentially in the container and packaging industry or heading towards landfills. The world over awareness of the potential of this material doesn't seem to be significantly seen in the Indian construction industry.

Environmental concerns

With the rising consciousness of environment conservation and green construction recycled glass has come up in several innovative and decorative construction products. Recycling of glass seriously cuts costs of raw materials and energy/fuel. Since glass can be recycled indefinitely as its structure does not deteriorate when reprocessed. Countries like Switzerland and Finland recycle more than 90% of their container waste.The process

Waste glass is collected from various sources and collection schemes like bottle banks, kerbside schemes or directly from parties using large quantities of glass containers. In India the kabbadiwala is a major link in this chain. These collections and glass rejected due to breakages and manufacturing defects together form glass cullet. Cullet may have added materials in the form of plastic, aluminum etc. that can change the properties of the cullet. After pulverization, the aggregate has a texture similar to natural sand and is as hard-grained.Combined with concrete it produces a material with a higher abrasion resistance than similar mixtures using quartz sand. There is also often a reduced drying shrinkage in these mixes. Powdered glass is polozzolanic, or it contributes to strength development by reacting with lime. Though these strengths are lower than Portland cement alone there are distinct economic advantages of using the material.

Product innovations

Tumbled glass: These are recycled glass pieces that have a frosted surface and rounded edges. These pieces widen the scope for innovation in interior design, mosaics and landscape accenting. They are suitable for incorporation into tiled surfacing, architectural glass designs or to feature in reflecting pools and fountains. Tumbled glass may also be used as ballast gravel in green roof and other green building applications.

Abrasive/ blasting media: Crushed recycled glass is a safe and effective medium to substitute natural sand and slag. It is applicable for sandblasting work like surface preparation, removal of rust or paint, etc. With its lower weight it is easier to use and dispose off.

Water Filteration media: Finely crushed recycled glass presents itself as a direct replacement for silica sand. It has shown its advantages in being lighter, more hygienic and safer to use than silica sand. As a light weight product it provides more filter volume per unit weight. These products have no crystalline silica and do not trap bacteria resulting in lowered requirements of chlorine and coagulants.

Building material from glass: REAPOR is a fiber-free building material for thermal and acoustic insulation using recycled glass. Developed in Germany, it has the advantages of being light weight, stable and water-, acid- and fire- resistant. In terms of workability too the material scores high. Adjustments to the material can be made in terms of desired degree of thermal or acoustic insulation and weight requirements. Further it is environment-friendly being made with 90% recycled glass and is itself fully recyclable.

Façade Engineering

3i-isolet blocks

GK Construction from Austria is working on introducing its innovative insulated building block in the middle East. The blocks are ideal in the construction of partitions and walls in multi-rise buildings and also can be used as load-bearing walls in two and three-storeyed buildings and in the construction of housing projects. The product has already been tested in European labs and projects for parameters such as heat insulation, fire resistance and moisture resistance. The blocks are insulating with the integration of insulation systems within the building materials. Due to the integrated special assembly 3i-isolet products are easy to build and to assemble. Made of recycled materials they can be reutilized for building material. The products – 3i-vario, 3i-deko and 3i-multi variants—are applicable for structural engineering in interior and exterior construction such as professional fascade construction, renovation of old buildings and constructional safety devices.FACE rain screen system

The FACE by Soladrilho terracotta rain screen system comprises of extruded terracotta/ceramic tiles and an aluminum substructure with steel inox clips. Marketed in UK and Europe the product has advantages that include low maintenance and ease of installation.A ventilated facade has growing importance in modern architecture, not only for technical features, but also for the aesthetic appearance. The ventilated facade system relies upon the fixing of terracotta/ceramic tiles on an aluminum substructure previously fixed to the construction facade. The horizontal joints between tiles are left open to the cavity area of the cladding zone allowing its ventilation.

The substructure can be specifically designed to allow lightweight stud infill panels between the floor slabs if required, with the main vertical rails being fixed direct into the slab edge on each floor. The FACE rain screen system is also very fast to assemble and fix on site in comparison with traditional construction and even other methods of rain screen and it requires no wet trades.

Bent glass

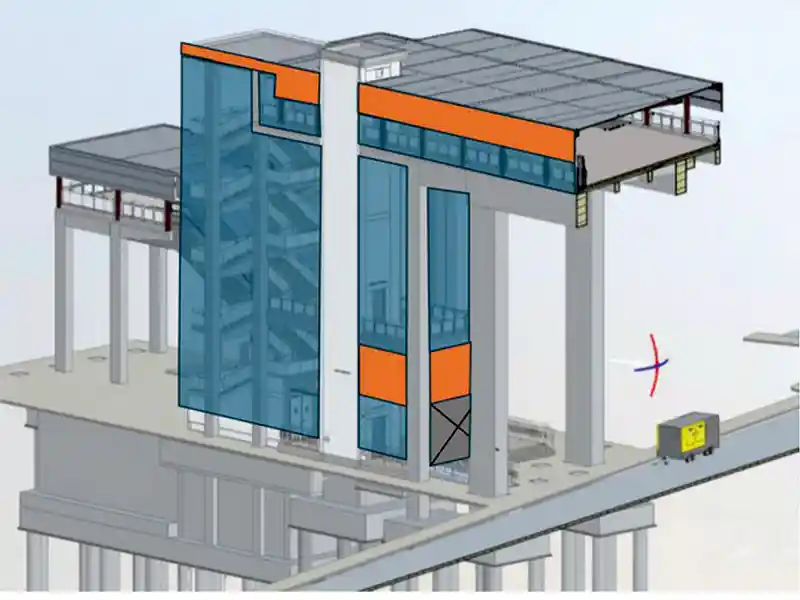

Bent glass has been on the building scene since the early 19th century. This dynamic product is growing in proportion of its use with the development of glass technology, improving safety properties and the energy saving properties available in glass.Bent glass adds greatly to the aesthetic potential of design. The curved surfaces give a building its own personality, creating the whole or a part of the façade.

With a growing proportion of bent glass been processed to make safety glass, bent glass can also be laminated for specialized categories like bullet resistant. There is also widening scope of available products in terms of available sizes. This may then be increasingly used in both facades and interior architecture.

So far bent glass has primarily been used in public buildings, office complexes and for corporate facility facades. Interior architecture applications for bent glass include railings for staircases, walkways, partitions and elevator glass panels.