The New Delhi International Airport with its distinguishing feature of the wavy structural steel roof, the Kalzip membrane held by a large spanning steel structure in the Hyderabad International Airport or the Vidyalankar Institute of Technology in Mumbai using Galvalume sheets for roofing certify the fact that metal roofing today is no longer about hideous corrugated sheets only. New styles, profiles, colours, shapes, textures, designs and innovations like eco friendly roofs have seen the amelioration of metal roofing in commercial as well as residential architecture.

Jwellin Shah, General Manager of Sales & Marketing at Proflex Systems, a division of M&B Engineering Pvt Ltd, representing innovative self- supported roofing technology rightly states, "Roofing is like the engine of a car, without which it would not be called a building. The heart of a building, a good roof definitely adds value to the entire building."

While the initial cost might be high, but the durability and the absence of a need for a second or a third roof makes metal roofing a preferred choice. Also, metal roof with built in solar panels are considered the most energy efficient. The cost of metal roofing in residences though remains debatable and Leena Kumar, Founder and Principal architect of Bengaluru based Kumar Consultants feels that it's a mind block with the public since due to low loading in residential uses, metal roofing is a good option there too.

Types of Metal Roofs

Structurally metal roofing can be classified as structural and non structural/architectural. Whereas structural metal roofing is directly attached to purlins and eliminates the need of any solid support beneath, non structural metal roofing requires some solid support beneath in the form of plywood, a metal roof deck etc. Non structural systems would include tiles, corrugated metal roofing as well as panels. Metal roofs are available in sheets and sections. Sheets which come in standard sizes can be cut whereas sections are usually custom built.

Corrugated Metal Roofing used on large industrial constructions (especially on roofs that have steep slopes that shed water quickly) can be easily installed. Their disadvantages however remain during heavy rains when they make noise or during hailstorms when they can be prone to denting.

Cool Metal Roofing, a cost effective and environment-friendly roofing is found in the form of unpainted metal, pre painted metal and granular coated metal roofs. Both painted and unpainted metal roofs exhibit sustainable reflectance and emittance values in even the harshest environments.

Panchkula based Architect Siddharta Wig heading architectural firm THE ELEMENTS cites the reason of durability, longevity and aesthetics for using metal sheet roofing in his project - the recently completed St Anne's High School Auditorium. For this 1500 seater auditorium in Chandigarh - the largest in the city, a steel frame radial truss and powder coated steel sheet roofing has been used.

Advantages of Metal Roofing

Bengaluru based architect Fabian Ostner heading Fabian Ostner Architecture Studio Pvt Ltd maintains that in general metal roofing can provide a long-lasting solution with low maintenance, provided they are constructed consciously and without the need of a heavy (costly) support structure.

The advantages of metal roofing are:

- they have great fire resistance; hence one finds them in majority of industrial buildings.

- low end metal roofing lasts 20 years while some sheet materials can last up to 100 years. Most steel roofing come with a 50-year guarantee. There are high quality paint systems/coatings used on metal roofing to resist chalking and fading of their colors. Simultaneously, these paint systems help in shedding off the dirt and resist the growth of fungal matter leading to low maintenance too.

- in severe wind conditions, it has been found that metal roofs outlast other roofing products. Also, metal roofing is ideal in northern or mountainous regions since painted metals roofs help in snow shedding.

- with coatings of various colors and patterns, and availability in a number of profiles, metal roofing offer extensive design flexibility to architects.

- There is no denying the strength of metal roofing and they are amongst the lowest weight roofing products - a benefit in seismic areas and in retrofitting projects. This also reduces the load on the structure.

- Most metals can be recycled without losing any valuable properties leading to eco-friendliness. Aluminium and copper roofing products are generally available with 95% recyclable content.

- Installation and construction is easy and quick and in many cases metal roofing can be installed over existing roofs also, saving costly tear off.

- Metal roofs reflect heat effectively, thus minimise the heat of absorption leading to lowering of air conditioning costs.

Disadvantages of Metal Roofing

- The difference in temperature or the sound of falling rain sometimes can produce noise like in case of curved or corrugated metal roofing. This can however be avoided by proper installation and using roofing material that contains structural barriers to minimise the sound effect.

- Initial cost is expensive.

- Dissimilar and incompatible materials can cause unexpected and rapid corrosion.

- Transport of metal roof components is an energy intensive activity.

- Metal roofing renders the interiors warmer but Fabian mentions that with the use of an insulating layer (air-ventilation, insulation material such as Styrodur, Thermocol etc) one can easily control the radiation to the interior.

Considerations for Metal Roofing

Fabian points out that one needs to look at the budget, the availability or eventual transportation costs and the overall sustainability of the use of metal. He warns that one has to be aware that the mining, milling and processing cost of the various metals (be it mild steel or aluminium) needs a large amount of energy and is often connected with damages to the environment.In the factory for Bhorukha Gases in Bengaluru Leena, has used a curved roof to reduce on steel since it is self- supporting and therefore trussless. "In this case, the form was pleasing, the roof height was high, lighting was ample, and the only detailing it required was the gutters for rainwater drain-off. The collection of rainwater for harvesting and re-use became simple and construction was executed fast and early", she adds.

Shah cites cost, process of installation, time frame, aesthetics, project suitability, location, present trends in the industry as considerations for metal roofing. What also needs to be determined is if one wants to go in for a single layer metal roofing or individual metal materials placed together. "Not all metal roofs can be easily installed on existing roofing", he chips in.

The most commonly used metal roofing materials include steel, aluminum, copper, zinc, and titanium. Metal alloys in different colours, styles and textures are also available. Wig mentions that longer purlin spans, lower slopes and choice of colours determine the material.

The various options in case of materials are:

- Copper – the most expensive of all materials, the roofing is beautiful and is generally used in smaller places. Though prone to weathering to a green colour with time, it is resistant to corrosion and does not need to be painted. Care has to be taken to avoid direct contact with other metals. It has value in recycling.

- Aluminum- A very preferred choice - it is lightweight, durable, ductile, malleable and corrosion resistant. It has a light reflectivity of over 80% and is used to a great deal in industrial buildings. One needs to avoid direct contact with dissimilar metals, concrete or mortar; and moisture entrapment during storage to avoid staining.

- Zinc- Resistant to corrosion, it's durable (a lot more than steel too) and can be recycled. The only downside is the very expensive initial cost.

- Steel – One of the most common, steel is an inexpensive material. Its strength and its prevention from rusting by using a zinc coating, a sealant or some paint are some of its advantages. Steel sheets for roofs can be manufactured from colour coated Galvalume/Galvanized, Soft Steel and High Tensile Steel.

- Titanium- It has high strength, is light weight and is immune to atmospheric corrosion

- Tin- Commonly seen in Indian residential metal roofing they are a great prevention from the winds.

- Stainless Steel – With a lustrous finish it doesn't need any extra coatings, but its built-in anti corroding properties make it expensive. After installation, the surface needs to be cleaned to remove contaminations that can lead to surface corrosion. Space frames are popular in stainless steel.

- Galvanised Steel - It is steel coated with zinc which is often used in commercial and industrial applications. It is economical, can come in direct contact with concrete and masonry, is light weight and durable. It needs to be insulated with bituminous coating if it's going to come in direct contact with copper.

- Alloys - Different metal alloys are good for metal roofing; the cost however depends on what the alloys consists of. Terne metal (zinc-tin alloy to cover steel) is light weight, durable and has low expansion though it cannot be nailed through metals and must be painted soon after installation. Also, it needs to be primed on both sides before installation. Then there are alloys like galvalume or zincalume (blend of zinc, aluminum and silicon-coated steel) which are more widely used as a base metal under factory coated colours.

Coatings

Nanotechnology solar reflective coatings are efficient heat reflective coatings which help in reducing the heat load on buildings with metal sheet roofs by 30%. They also help in extending the lifespan of the metal roofing (since the metal expands and contracts less due to lower temperature variations). Some also include titanium dioxide, which makes the roof self-cleaning.

Coatings are available to make aluminium and stainless steel look more natural. Steel can be coated with Terne for a flat gray appearance which would subsequently weather to a soft grey finish.

Metal Roofing in the Market

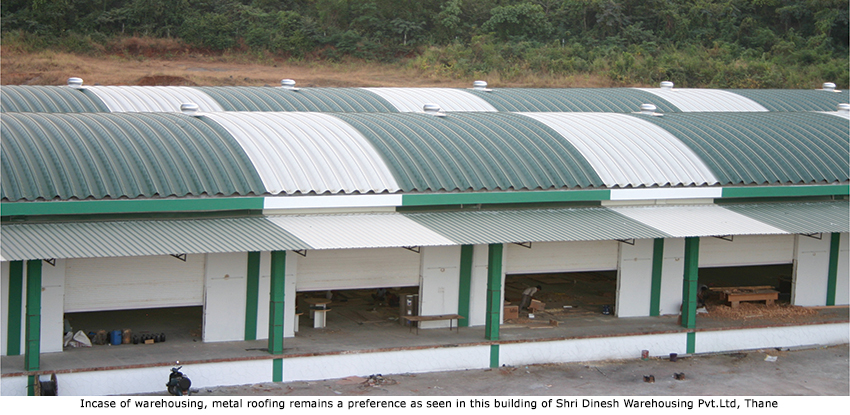

Proflex Systems currently has self- supported steel roofs. An ideal solution for warehouses, it is always available in arc shape and is considered to be the fastest roofing technology in the world as they can practically install 10,000sqft in one day. Shah adds, "Absolutely maintenance free, it does not have any nuts or bolts in between, is 100% leak proof and provides a very clean environment. And though at present, we have only steel roofing but we certainly look forward to have more metal roofs like aluminum, copper, brass etc."

Ahmedabad based Nexus Infratech Pvt Ltd provides Spider Roofing made of Galvalume Steel. With modern high performance paint systems the resultant system offers durability, versatility, light weight, structurally strong and economic roofing. The application of such roofs can range from auditoriums, to industries, recreation parks, aircraft hangers, restaurants, sports stadiums, shopping malls etc. Galvalume gives double service life to a galvanised sheet with the same thickness of coating, is corrosion resistant, resists high temperature and has better heat reflectivity, and doesn't oxidise.

SMARTRUSS® system being offered by the premium brand LYSAGHT offers a revolutionary kind of steel roof supporting system. Customised, accurately designed and detailed trusses can be manufactured as per building specifications. Assembled on site or prefabricated off site, these can be delivered and pre-assembled in transportable lengths. Light in weight and high in strength they are made of Zincalume Steel.

There is SMARTROOF - a unique roofing system (corrosion resistant and rainproof) being introduced in India by Intermark Associates Pvt Ltd, comprising an openable array of specially designed extruded aluminium louvers. It is used for covering courtyards, swimming pools, patios and terrace gardens – all outdoor entertaining areas. By the simple flick of a switch, one can also control the movement of louvers to an angle which ideally suits your need and the mood of the moment and can control light, heat etc. The framework which is made in MS rectangular hollow pipes can be fixed to walls or stand alone columns too. Much lighter in weight it's a treat in the numerous amount of courtyard houses that we see today.

Skyarch Roofs Pvt. Ltd. offers Skyroof Brand roofing systems which are used in industrial and commercial roofing services with precoated profiled Galvanized Steel Sheets, Profile Bare Galvalume Sheet; Profiled colour coated Galvalume Sheets. An aesthetic appearance, high durability, light weight, high strength, easy maintenance and cost effectiveness are some of the advantages. They can be implemented in Food Court Areas, Factory Buildings, Factory Shades, Auditoriums, and Parking Areas etc.

Installation And Maintenance Issues

Shah is of the view that the metal roofing installation process is more defined and accurate as most of them are factory made, but certain pre-requisites are important. Fabian adds that since metal construction types can range from very articulate structures to extremely simple assemblies, it can be done by few people without much training and thus reducing labour cost.The installation is fairly simple and uncomplicated but Leena adds, "If the tools are not good, the end results are shabby, especially in the case of cross-cutting. In some cases, where welding is required as a detail, the metal sheets being so thin in its gauge, pose a major problem." Wig mentions, "There is a problem if you are cutting diagonally and getting a ridge in. Cut edges tend to rust over time, and tend to initiate peeling of the paint."

Close attention needs to be given during the installation of metal roofs since a slight deviation could result in roof leaks. Metal roofing materials can be very sharp and cuts can very easily occur. Also, the roofing materials must be positioned correctly and secured just right so that the roof is structurally intact when it's done. One needs to keep in mind that metal roofs have a tendency to contract, expand and shift because of the heat and cold.

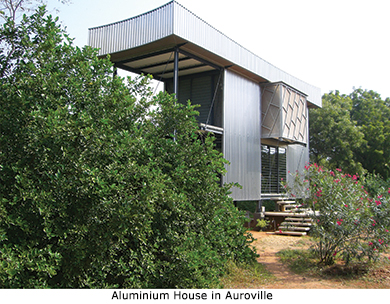

With regard to maintenance issues, Shah assures that metal roofing has the least maintenance as compared to other material roofings. Fabian recalls using sheets of aluminium fixed to a steel support frame for two houses in Auroville. He adds, "Both structures are now several years old and aside of a touch-up of the paint of the steel frame, the aluminium sheets almost look as they did when they were assembled with a little patina added. The assumed protection against the heat has proven effective."

Roofing material from zinc, copper, stainless steel will rarely require maintenance over their lifetime. If required the maintenance would be due to the design or installation mistakes. Then there are metal roofing with coating of paints which won't require any maintenance unless the paint fails. Metal roofs which have coating of acrylic or polyester based paints will require recoating. Also, one needs to consider protection against corrosion and the fact that metal would lose most structural strength in the case of fire.

Fabian positively concludes, "One can see everywhere in India resourceful and incredibly creative examples of very minimalist and simple metal constructions. Most of these structures are built using a minimum of material put to a maximum use, assembled by creative people mostly with a gas cutter, a set of pliers, some screws and eventually a hired welding machine. In most of these cases, the maintenance is kept relatively low and once the material has corroded or bend beyond its limit, it will be simply replaced."

ROOF INDIA 2011 - the 10th edition in "ROOF INDIA" series will be a much bigger highlight to find out about different kinds of metal roofing. Catch it at Mumbai from 27-29 May 2011.