Mahendra Pingle DGM – Market Development Tata BlueScope Steel

Pre-painted steel products may offer increased corrosion resistance and enhanced aesthetics compared to bare metallic coated steel (ref- Galvinfo, Note 4.1) The performance of a particular pre-painted product in a particular application and environment will depend on both the metallic coating type and class, and the paint system design and formulation.

Factory Pre-Painted Metallic Coated Steel

The factory pre-painting process is typically conducted on a continuous paint line (CPL). Firstly, the metallic coated strip is cleaned and a pretreatment is applied. A primer is then applied in the prime coater, and finally, a topcoat and backer are applied in the finish coaters. Each paint layer is oven- cured at high temperature 210 – 250 deg C. This continuous process helps provide a consistent product and leverages decades of paint and metallic coating technology development and innovation.A premium pre-painted steel product used in building applications will typically have:

- A steel base of a specific grade and thickness needed to meet the structural requirements of a particular design and application, e.g. 0.42 mm BMT (Base Metal Thickness) G550 grade.

- A metallic coating of a specified coating type and class, e.g. AZ150

- A chemical pretreatment that increases adhesion between the primer and metallic coated substrate and also enhances corrosion performance.

- A primer layer that improves corrosion resistance and topcoat adhesion.

- A pigmented topcoat layer to provide the desired surface properties (e.g. aesthetic appearance, damage resistance and/or antimicrobial activity). Key components of the topcoat paint include;

- Pigments which provide colour, opacity to UV light, and solar reflectance,

- Solvents which modify viscosity, allowing the paint to be applied as a liquid,

- Additives which are used for a variety of reasons such as altering gloss levels, increasing durability, and improving the appearance of the paint,

- A polymer resin that provides the overall matrix which binds the pigments and additives together, and provides durability and formability.

Key Benefits and Attributes of Factory Pre-painted Steel

Two important benefits of pre-painted coated steel are the improved aesthetic appearance and the increased time to corrosion perforation. Performance in regards to these benefits will depend primarily on the paint durability, colour retention, and overall corrosion resistance attributes.

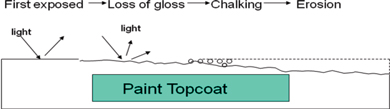

Figure 1: Weathering of a paint topcoat showing the degradation over time

In regards to corrosion, the metallic coated substrate is still a key factor. However, the paint system provides additional barrier and corrosion protection. The effectiveness of the paint as a protective barrier film reduces as the paint erodes. Corrosion protection at cut edges and at piercings will also depend on the paint and primer formulations and how robust they are. In addition to corrosion ultimately leading to perforation, unsightly corrosion will also impact the aesthetics of the pre-painted product.

These attributes are examined in more detail below.

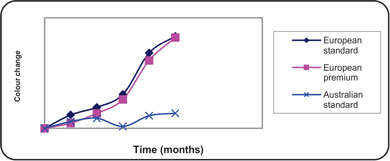

Figure 2: The change in colour (dE) measured on samples of blue European polyester paint systems compared with a blue Australian designed polyester paint system i.e. Colorbond steel.

The typical stages of weathering are shown in Figure 1.

It is important for a paint system to be designed to resist weathering in the specific environment in which it is being used. In Australia (similar conditions to India too), this generally means resistance to combined high temperatures and high levels of UV light. Pre-painted products designed specifically for these conditions will incorporate the highest quality resin binders and pigments to ensure that the rate of chemical breakdown of the binder, and therefore the rate of weathering, are minimised. COLORBOND® pre-painted steel product is specially design for exterior application having high degree of reistance to weathering.

Colour retention: Colour retention, or the resistance to colour change, is primarily determined by the pigments used in the topcoat. Paint durability is also a factor as the colour may change as the paint weathers.

Colour pigments can be either organic or mineral/ceramic based. Organic pigments are often brighter and may have greater tint strength. This means less of a particular pigment can be used to achieve the desired colour. Organic pigments can also be blended with the polymer or resin part of the paint more easily during manufacture. Hence, organic pigments typically offer a cheaper route to achieving a desired initial colour. However, they are typically less colour stable than mineral pigments, particularly in environments subject to high levels of UV light, (such as Australia), and will fade much more rapidly. Mineral and ceramic pigments normally have much greater environmental stability than organic pigments and are, therefore, key to producing topcoat paints that are resistant to high UV environments. COLROBOND® pre-painted steel uses inorganic / mineral and cemamic pigments for improved color retentions than other PPGL / PPGI product.

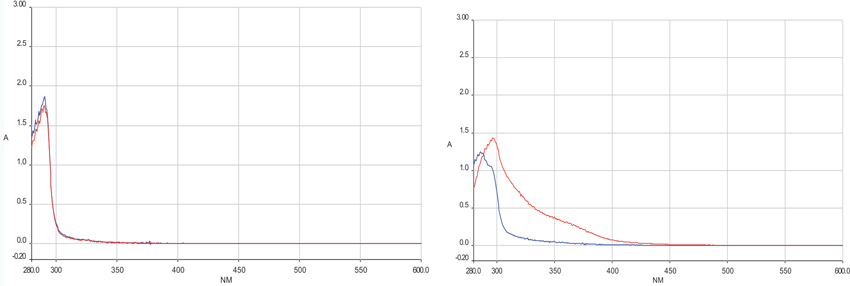

Figure 3. UV absorption of (left) Australian prepainted sample and (right) market Standard pre-painted sample. The blue line is the measurement of UV absorbance prior to heat resistance testing, while the red line is the measurement of absorption after heat resistance testing.

Case Study – Design for Environment – Pigments

Not all pre-painted products are formulated to withstand Australian conditions. Figure 2 shows the behaviour of pre-painted steel exposed at an outdoor exposure test site in Queensland. The European designed paints exhibited significant colour change after 3 years compared to products developed for Australian conditions.Different manufacturers have different approaches with respect to pigment selection. Those with the highest performance requirements and most robust product evaluation and approval processes, involving rigorous accelerated and environmental testing, will help ensure customer expectations are met or exceeded.

Other paint components such as the resin and additives like UV absorbers will contribute in varying degrees to colour retention. A durable resin will maintain its inherent UV resistance longer than a less durable resin that breaks down faster and ultimately weathers away. Additionally, more durable resins will degrade or "chalk" more slowly and therefore contribute less to colour change.

Case Study – Design for Environment – Resin

Under hot conditions outdoors, many paint resin systems are broken down by thermal-oxidation reactions. The sites of oxidation damage are susceptible to further breakdown by UV light.Manufacturers of premium products suited to Australian conditions include resistance of the resins contained in the paint to this thermal oxidation process, as one of the principal criteria for designing durable paint systems.

After testing both the market standard pre-painted steel and Australian designed pre-painted products (COLORBOND® XRW steel) in a laboratory for 1000 hours at 95°C, the absorption of UV radiation by the market standard sample is significantly increased, while the Australian sample has little or no change, as shown in Figure 3. The observed changes are indicative of actual changes in the resin as a result of chemical degradation.

Case study – The impact of resin and pigment combinations

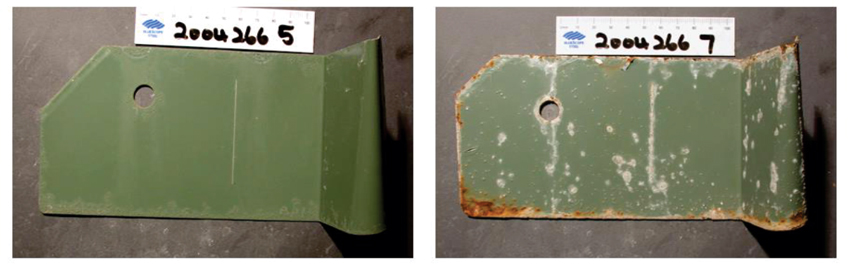

Figure 4. Samples of imported (top) and Australian designed prepainted steel (COLORBOND® XRW steel) after 4 years on a hot rack at Rockhampton. The small control samples on the left were stored under ambient laboratory conditions for comparison

Corrosion Resistance: Corrosion may occur as undercutting at cut edges and piercings, at scratches, or under the paint causing blistering. Even the best paint systems will eventually weather off after many decades, exposing the metallic coated substrate.

Paint is generally described as providing barrier corrosion protection to coated steel. It should be noted, however, that paint is not completely impervious to moisture. If panels are wet for long periods of time, water molecules may penetrate the paint and reach the metallic coating (Ref Galvinfo, note-4.1). Pre-treatments and primers play an important role in enhancing corrosion resistance to blistering, as well as cut edges, and perforations. Corrosion of the metal coating under a paint system can be visible as blistering of the paint in the early stages.

The metallic coating type and class also plays a critical role in the overall corrosion resistance of pre-painted product. Real world performance indicates that different metallic coatings will have significantly different corrosion performance and durability under paint. The corrosion resistance of different metallic coatings under paint impacts the overall time to perforation and aesthetics. Variation in corrosion resistance effectiveness means that different coating types will require different metallic coating mass (typically measured in grams per square metre) to meet the performance requirements of standards such as AS/NZS 2728.

Case Study – The impact of Metallic coating on Pre-Painted product corrosion

In terms of corrosion protection of pre-painted products, the most important protective mechanism is provided by the metal coating. Long-term exposure and building evaluation shows that pre-painted AZ150 has an expected life significantly greater than pre-painted Z275 in many building applications.Figure 5 shows that for the same paint system, corrosion is significantly worse on the Z275 coating, than on the AZ150 coating in some environments.

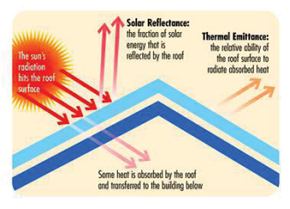

Thermal performance : Historically, the pre-painted finish on metallic coated steel has primarily provided an attractive finish and enhanced corrosion resistance. Paint can also contribute to the environmental impact of a building by altering its thermal properties. That is, the amount of heat retained by a building can be minimised by using materials that reflect the maximum possible amount of incident solar heat. This is known as 'cool roof' technology. Cool roofs provide a range of benefits, including building energy- efficiency, and improved human comfort.

Figure 5: Prepainted panels exposed for 66 months at Bellambi Point, Australia (unwashed severe marine) AZ150 (left), Z275 (right) – both with the same paint system

Cool roofs are characterised by having a high solar reflectance.1 The coolest roofs are typically white. However, technology has also been developed to improve the solar reflectance of darker coloured surfaces. Specialised pre-painted products incorporating this technology are available to assist in maximising the thermal performance of buildings.

Figure 6: Cool Roof Impacts.4

Figure 6 shows a schematic of the thermal surface properties of a roof and how these properties affect roof thermal performance2. A primary benefit of cool roofing is its ability to reduce the heat transferred into the building below, reducing the building's requirement for air conditioning.3

1 Lovins, A. B. (2011), Reinventing Fire®: Bold Business Solutions for the New Energy Era. Chelsea Green Publishing, Vermont, USA. P. 108.

2 Cool Roof Rating Council, JPEG, Last Accessed July 2012, http://www.coolroofs.org/images/Diagram_1_002.jpg

3 Yan, R and Adams, J. (2012), Cool Roofing – An examination of the options to reduce capital and/or operating costs of retail buildings in Australia, BSR/N/2012/039. July 2012.

The thermal properties of pre-painted metallic coated steel may be another consideration for building designers and owners, in addition to paint durability, colour retention, and corrosion resistance.

Key Points

- Factory pre-painted metallic coated steel is a multi-layered product where the paint system may be designed to provide optimum aesthetics, paint durability, solar reflectivity, and corrosion resistance.

- The corrosion performance of a factory pre-painted coated product in a particular environment is a function of the sum of the coatings (metallic, pre-treatment, primer, backer, and top coat), and how well they interact with each other.

- Not all paint systems are designed to withstand the high UV and temperatures of the Australian environment, with resultant rapid weathering and colour change of poorly designed systems.