Global Aluminium (P) Ltd. (GAPL) with an ISO 9001-2008 certification, is one of the leading manufacturers of high quality aluminum extrusion sections which roll out products exactly matching to consumers' requirement. The practice of delivering quality products has pushed the company to its current stature.

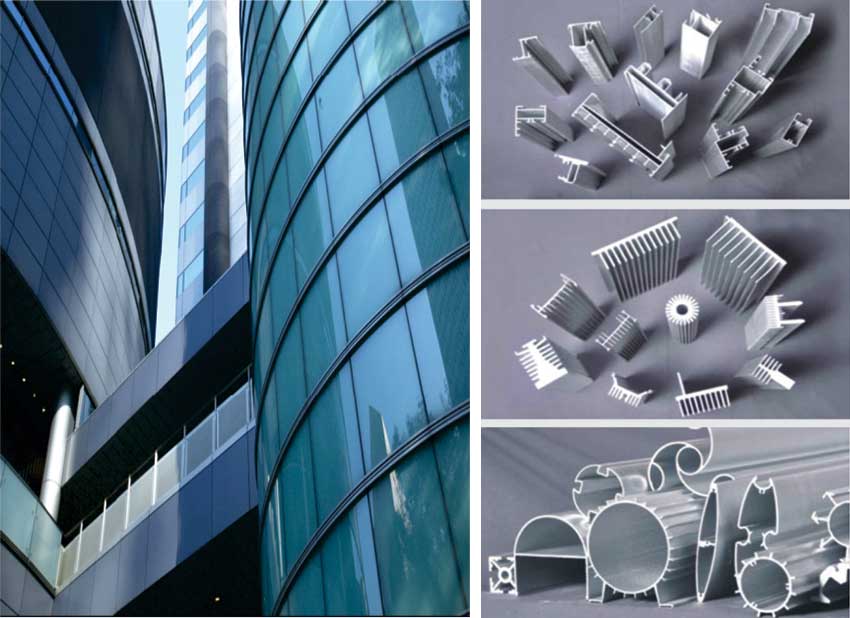

Commanding an expertise of over 15 years and an installed capacity of 32,000 TPA, GAPL enjoys a comprehensive understanding of the aluminum extrusions market, demand trend, challenges and opportunities. In view of this, it is manufacturing high quality aluminium products for varied applications including Architectural, Building construction, Automobile, Defense and Aerospace, Electronics and Electrical, Hospital Equipment, Industrial & Engineering, Solar and Wind Power, Transportation, and Telecommunication.

Giving blow-by-blow details, an official spokesperson said that GAPL was set up in 1997 with a 1000 TONS press but currently operating 9 extrusion presses with fully automated PLC control systems strictly adhering to international quality standards. It possesses two in-house facilities, both located at Kallakal Village, Hyderabad. Unit-1 sprawl over 9 acres (40,000 sqm) with a built-up area of 10,700 sq.m comprising in-house Foundry with 5 Extrusion presses and die maintenance shop whereas unit 2 spread across 30 acres (1,40,000 sqm) with a built-up area of 21,400 sqm consisting of 4 Extrusion presses, Online Surface Treatment: Anodizing, Powder Coating & Wooden Finish and die manufacturing and maintenance shop.

Elaborating further he said that GAPL has been setup with most advanced equipment, latest technology and 100% power back up facilities with modern in-house foundry with hi-tech melting furnaces along with hot-top casting. The dies are manufactured in H-13 grade alloy steel with latest CNC Machines with CAD-CAM software. There are more than 15,000 dies for 7000 different profile. The manufacturing unit has been equipped with precision controlled temperature ovens for T4, T5, T6 tempers. The quality standards are maintained with Spectrometer, UTM and Hardness Tester along with other precision measuring tools. The Smooth surface finish is obtained with in-house anodizing, powder coating & wooden effect finish.”

Before wrapping up conversation, he further reiterated that GAPL is delivering the best quality aluminum products with wide range of clients reach. It is committed to continuously making improvement in the supply of various genuine, trusted and unmatched quality aluminum products to meet the ever increasing market requirements with well oiled market delivery mechanism not just within the country but also exporting products to the global markets including Australia, USA, Canada, England, France, Germany, Kenya, Sri Lanka, and Bangladesh, among others.