SKYBRIDGE Structures Limited - Only to the Imagination

T. K. Abdul Sathar, M. Archineer (M.St)-Germany. (Managing Director, Skybridge Middle East).

About Company

Skybridge is a design, engineering and fabrication company for fabric tensile structures, specializes in Fabric Tensile Structures and have more than one million sq feet of fabric structure installation base in India, Qatar and Malaysia. With a wealth of design, manufacturing and installation experience, the company offers a fast and efficient turnaround of both large and product based structures, for all types of exterior, interior and exhibition environment.Employing a wide variety of fabric types, Skybridge creates any imaginable shape or form in any size to suit your design and budget. Company’s state-of- the-arts fabric and steel manufacturing facilities in Bangalore, have all the facilities to execute large membrane structure.

To meet the rigorous requirements of today’s environment many different fabrics are available. Skybridge provides simple, but sensible design advice. During initial consultation they work with the client, offering information on both design details and fast installations, finally providing budgets and quotations with confirming details 3D renderings of the possible structure.

The company have staffs with over 11 years of experience in the field of fabric architecture, from concept to visualization, design, engineering, manufacture and installation. They all are well equipped and trained with most relevant design software for membrane structures from Germany which has been used for most of the major Olympic stadiums and outstanding structures worldwide. Also their design teams are leading by qualified designers from German Universities, and their European design partners have more than 3 decades of experience in the field of membrane structures designing.

Technology Behind Tensile Structure

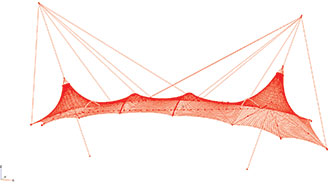

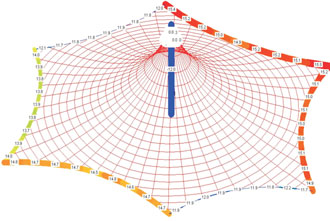

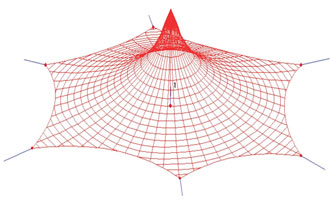

For lightweight structures, the structural forms (shapes) need to be determined through a tedious optimization process.

Generally the form-finding is to provide the exact shape of structure. The design usually commences with a sketch drawn by the architect. This sketch provides the basis for further conceptual design. Because the membrane is flexible, the surface shape and structural stability is mainly governed by the stresses, either physical modeling or computer simulation of the structure is required to help the designer to find realistic shapes.

Statical Analysis

Material Properties: Biaxial tests

External loads: Codes (Laws),Wind channel

Solution: Energy method (equilibrium, material law and geometrical compatibility)

Cutting Pattern Generation

Another important part of designing of membrane structures is cutting pattern generation. This process includes the determination of the distortion- and stress-free lengths of all cable and membrane pieces as a prerequisite for the cutting of cable or membrane materials and their knotting and sewing together to form a structure. In the cutting pattern generation real material values are used. Moreover this step becomes important because the slack lengths determine the prestress in the structure when the structure is analyzed & checked under different loading conditions.

Historical Background for Convertible Membrane Structures

Reconstruction of the Roman Theatre Velum. The basic type of the vela consists of wooden poles and vertical rods that are connected flexibly by ropes. The sails could be moved parallel between the poles. By pulling the ropes, the angle of the roof could be adjusted according to the sun.

The oldest known picture of an umbrella is from the 13th century B.C. It shows the Assyrian ruler Assurbanipal with a sun umbrella; Umbrellas have been signs for power and wealth for a long time. The construction principle has not changed over centuries: A tension loaded membrane, a central rod and compression loaded ribs form one constructional unit.

The fabric lies on a cone shaped structure made from wooden rods. At the top of the tent, the smoke vent can be adjusted according to the wind direction. Moreover, the membrane can be bunched to an individual height.

Buildings with a moveable roof that can be retracted partly or completely are very different from permanently covered buildings in several respects. First of all, two different states have to be considered in planning the interior of the building. Thus it can be necessary to design the interior weatherproof. Moreover the mobility of some parts of the building requires the use of mechanical components from the field of mechanical engineering. The cooperation between architects, civil engineers and mechanical engineers is one of the big challenges during the planning of a retractable roof.

Environmental Responsibility of Membrane Structures

Most of the membrane materials are environmentally preferable products (EPP) to the greatest extent possible. Also it provide and promote stewardship of the earth’s resources, promote good indoor environmental quality, and promote efficiencies in operational performance.EPP’s include products that have low VOC content, high recycled content, and are manufactured, fabricated, or extracted within 500 miles of the construction site.

The present invention relates to a porous adaptive membrane structure that has movable membranes. The structure can be made to change its gas, liquid or particulate permeability in response to surrounding environmental conditions. The application of this invention is includes protective apparel that is comfortable to wear wherein the level of protection provided is based on conditions in the environment. Hence, the protective apparel is highly breathable and comfortable in a non-hazardous environment but impermeable or only semi permeable in a hazardous environment.

The architectural membranes selected for use in Structures have significant life spans from 10 to 50 years. Use of high quality membranes dramatically increases the time before a replacement will have to be installed. This reduces the amount of membrane required to be manufactured, reducing energy consumption from manufacturing thereby reducing impact to the environment. Comparably, membranes on tent like products typically have a 5 year life expectancy. This would require the manufacture of a number of replacements to equal the life expectancy of one architectural membrane Structures.

Ideas for a Temporary Limited Use and Recyclable Dismantling of Membrane Structures

Due to the light weight property of the membrane material and supporting structure it is easy for the transportation, construction, dismantling etc. compared to any other construction material. Also due the extra ordinary lightness and same time better tensile forces enable this concept to make very large span structures to accommodate maximum occupancy with the minimum structures and supports. Also the durability and resistance against the weathering and many other natural causes which is always threat for other construction material is another advantage of the easy handling of the membrane projects.

Membrane structures are all time better for the event structures and structures for the short time purposes. Due to the safety of the structures, adaptability, and easy installation and dismantling membrane structure are prominent in the field of ephemeral architecture. It allows future generations to decide what they want to construct in their ideas and concept and the type structure which they want to have their life styles in the future.

Another important factor is the recyclability of each items are using in the membrane structures. After many years the fabric can be recycled and can be produced many other fine products like bags, hose hold articles, pvc rods again can be used for the membrane structures, and many other use full products. The steel used in the structures can be used again for different projects or can be recycled for the new steel products. Almost all the items can be reused or recycled.

Aspects of Energy Reduction in Fabrication, Erection, Maintenance and Support, Removing or Dismantling Including Environmental Responsible Recycling of Membrane Structures

The fabrication and installation of the membrane structure is not complicated like the construction of civil structures. Hence it does not need much energy, equipments, man power etc, like other building constructions. The civil construction is time consuming and not pollution free as well. At the same time we cannot replace the whole civil constructions with membrane structures. There are certain differences offcourse in the applications. But some areas still can replaced with metal roofing structures efficiently in terms of light weight property and large span structures with out much supports.

The wide range of possibilities in membrane structures in terms of unlimited forms can be developed with the membrane structures, light weight property, adaptability, eco friendliness, durability, recyclability, simplicity of maintenance, the membrane structures has reached in the out standing position in the construction industry.

Also the property of illumination through the fabric allow diffused light inside the structure, this helps to save a large quantity of energy in lighting and the extra ordinary u value and k value enables this material to save air conditioning cost in the tropical and middle eastern countries.

Visual Environment

The translucency of the architectural fabric skin is the most valuable asset of the membrane structures. The extensive day light opportunities offered by their light transmittance (typically 10- 30%) mean that artificial lighting can often be dispensed with most of the day light hours, leading to significant energy benefit that can overcome the increased heating requirements.

Day Lighting Performance

Day light striking the fabric roof is diffusely transmitted in to the building and a membrane roof appears from inside as continuous luminous surface, with the intensity of its luminance varying with the local orientation of each part of the surface relative to the sun. High day lighting factors ( ratio of day light levels between inside and out side) in excess of 10% can generally be achieved in spaces enclosed by a tensile fabric skin, as compared to less than 3% in most conventional buildings where day light is only admitted through a limited set of fixed glazed openings. Even during a dull cloudy day, it is possible to achieved day lighting levels well above the minimum required illuminance for most of the activities.Engineering

Engineering and architecture are virtually inseparable in the design of tensile structures and Skybridge Structural Industries places very high emphasis on design that is functionally driven, believing their structures are all the more beautiful for it. Tensile structures offer a pure demonstration of the importance of quality engineering because every component is both functional and highly visible. Tensile membranes under stress need careful engineering look good, perform well and to survive years of use.

Skybridge Structural Industries’ in-house design team incorporates a strong engineering element, with all their designers having engineering experience or awareness. This makes the company a productive contributor to any construction project.

When integrating tensile membranes within a conventional building envelope the lateral loads transferred can be considerable, as tensile membranes rely on double curvature to resist loads efficiently. Skybridge engineering capabilities provide timely information vital to the overall design process of the load points. Tensile structure fall into two main types: those that transfer tensile loads into adjoining structures and those that contain the tensile loads within their boundary. The first type may generate large lateral loads, which may result in the need for additional reinforcement in existing structures. Likewise a typical ‘lightweight’ canopy with masts and cable tie backs to ground level will generally need significant concrete foundations or screw anchors to resist the tensile loads. Loading analysis derived from a computer model is offered to all clients where it is felt that there is a need, and can give typical loads directions and the size of the design loads. The shape of a membrane surface is determined by the ratio of pre stress in the two principal directions of curvature, established in the computer form generation process. The absolute values of pre stress are calculated to be sufficient to keep all parts of the membrane in tension under any load case.

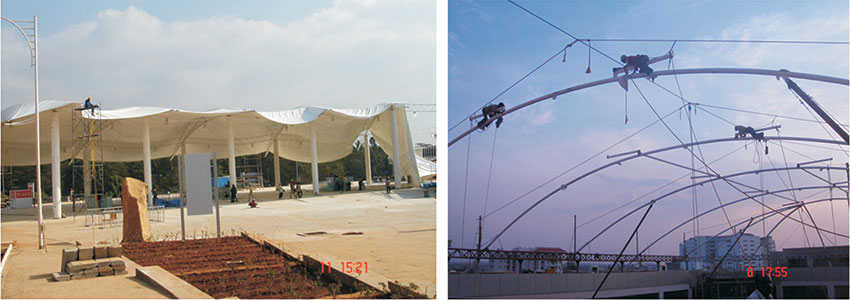

Fabrication, Installation and Maintenance

An appropriate erection method has to be developed and followed for the membrane erection. A stage by stage stability check, handling of material, site situations, whether conditions, will be taken care of. Designers will to final erection calculations and the magnitude of the forces which are to be applied in pre determined sequence of assembly. These calculations also determine to what extent the loads can be absorbed by the supporting structure and whether additional precautions have to be taken. The erection calculations are an essential part of the calculation and drawing dossier.

Critical to the success of a project is the skill and coordination of site operations, and the construction and installation of tensile structures often involves potentially high risk operations, with demanding access requirements or complex lifting operations. Skybridge group has a strong team of experienced and accomplished riggers, fabricators, site and installation managers who specialize in the fitting of tensile fabric structures.

The degree of maintenance that a tensile structure requires depends on factors, like design, function, aesthetic expectations, materials, site environments etc… This may range from ‘practically maintenance free’ to ‘regular maintenance required’. The development of maintenance concept should be integrated in to the design process inorder to meet the project related requirement. An annual visual inspection, plus inspection following weather conditions are recommended as a minimum requirement. The typical maintenance requirement is considered in six parameters:

- Cleaning

- Corrosion

- Water Drainage and Ponding

- Prestress and Restress

- Repair and

- Replacement.