Indian engineering industry has witnessed an extraordinary growth in the last few years as a result of increased investment in infrastructure development and industrial production. Growth in the domestic engineering industry has been fuelled by growth in key end-user industries and many new projects undertaken in various core industries such as railways, power, and infrastructure. The engineering industry plays a significant role in the development of other industrial sectors in the economy. This sector is very closely linked with the manufacturing and infrastructure sectors of the economy.

Capacity creation in sectors such as infrastructure, oil and gas, power, mining, automobiles, auto components, steel, refinery, and consumer durables has driven growth in this sector. For example, the domestic sales of automobiles have grown at a CAGR of around 18% over the past four years thereby increasing the demand for quick engineered infrastructural requirements. (Source: A brief report on engineering sector in India – by CCI – Sept 2012)

Besides the growing demand, what has been aiding the engineering industry in India is the availability of technical education infrastructure that provides an increased number of technically trained human resources every year. Further, India is being preferred by global manufacturing companies as an outsourcing destination due to its lower labor cost and better designing capabilities.

Interarch Infrastructure is a new SBU of Interarch which will look after Heavy engineering and large infrastructure projects in the country. The best merit of bifurcating into this division is its diverse application. Right from the multi-story buildings to multi level car parking structures, terminal building structures, aircraft hangars, stadiums, auditoriums, railway station structures, metro stations, large workshops, flyover support structures, bridges, and highway toll structures are just a few to name. Steel structures are highly suited to diverse applications within the infrastructure space due to the speed of construction and durability of the material.

Heavy Engineering is a sunrise sector within the steel construction space and hence we have created a completely new and customized business to exclusively cater to our customers. We will now have a focused division looking after the large infrastructure projects across the country. The sector is expected to grow in the future and has a positive outlook owing to infrastructure development, favorable government policies, and new investments in power projects, metals, oil & gas, and petrochemicals industries.

As we are delivering projects across sectors for various prestigious clients, we have seen that demand for construction of large infrastructure projects in steel has been pacing up. The government has thankfully been friendlier in its norms and regulations for the infrastructure sector in its 12th 5 year plan.

Interarch Infrastructure will act as an end-to-end solution for Design, Engineering, Manufacture, Supply & Execution of any type of steel structure for various applications such as, highrise multi-storey buildings for various uses residential & commercial, hospitals, hotels, school buildings, multilevel car parking systems, stadiums, airport terminal structures, aircraft hangers, Port structures, shopping malls, retail outlets, power plant buildings, multiplexes, exhibition halls, street bridges, flyover structures and various other applications where steel structure is more effective as compared to any other method of construction.

Interarch solutions for infrastructure in steel offers wide range of projects work including all support structure requirement for utility, glazing work, façade supports, staircase, lift shaft structure, studio building and its support structure, heavy duty gantry supports for any size and capacity.

The revised highrise construction norms are certainly proactive and conducive. We need more support from the government to encourage use of steel buildings for educational institutions, hospitals, hotels & commercial buildings in all sectors with liberalization in duties on steel to make it competitive compared to RCC.

Steel structures are highly suited to diverse applications within the infrastructure space due to the speed of construction and durability of the material. Worldwide, use of steel is more preferred material than any other material including concrete due to its versatile unique features and advantages over other materials. Steel provides greater flexibility, less space occupancy, less volume to mass ratio, easy to construct, faster construction materials compared to all other construction materials available worldwide. A combination of steel structure with concrete is considered the best and the fastest construction material worldwide. Some of the features of steel structure as construction material for high rise and heavy duty construction are as under:

- Steel offers speed in construction, saves time resulting overall cost cutting

- Steel structure is faster to erect compared to RCC frames being lighter in weight

- High strength to weight ratio

- It results in very much reduced load on foundations resulting less cost of foundation as well as time saving.

- Steel construction takes much reduced time at site activities plant, material and labor causing little disruption to normal life of the community unlike wet concrete construction process.

- Reduced project time results in early occupancy and economic advantage to the investor/owner

- The use of steel makes possible the creation of large column free internal spaces. This helps in for open plan offices and large auditorium and concert halls.

- Use of steel compared to RCC, results in sufficient extra space to accommodate all services pipes, conduits without significant loss in head room.

- Alteration or strengthening of floors or columns is relatively easy in steel frame compared with concrete frames.

- Material handling capacity required at site in steel construction is less than concrete

- Steel structure occupies lesser space of floor area compared to RCC columns for multi-story structure. Brick wall and RCC construction always occupies larger space and heavy dead weight on the framing system resulting more cost and time.

- Steel frame construction is more suitable to withstand lateral loads caused by wind or seismic/earthquake

- In steel construction, steel x-bracing or sheer wall system can be provided for greater lateral rigidity in order to withstand wind stress.

- Steel material can be recycled/re-used after its life cycle and is having highest recycled aspect.

- Being off site manufacturing, steel structure quality and finish can be maintained to the highest degree.

Interarch Infrastructure offers complete solution from concept to commissioning for all type of steel structure as one-stop solution for all such type of applications in its domain. State-of-the-art manufacturing facility with the best material management and transfer techniques, in-house design and engineering capabilities equipped with latest design software such as, Staad/StaadPro, BoCAD, TEKLA, ProSteel, AutoCAD, Revit Structure, ZWcad, and various international design and detailing software to meet the customer expectations. Interarch steel structure solution exhibits following features as basic standard:

- Use of high strength steel of yield strength from 345 Mpa to 550 Mpa

- Use of hot rolled steel sections from 245 Mpa to 550 Mpa yield strength of various sections such as H, I, C, L, U or hollow sections etc. to achieve max. Steel optimization

- Cold form steel for light framing system

- Cold form metal decking system

- Sheer stud to meeting concrete steel bonding need for composite construction

- Shot blasted steel framing to international grade of surface cleaning of steel

- Corrosion resistant priming on steel frames/members

- Standard painting on steel of low VOC using Synthetic enamel paint or Epoxy paint or any other type of customized paint application

- Fire resistant painting to meet safety requirement as per governing law (Optional).

- High strength bolts for primary and secondary framing system with minimum 8.8 grade steel

- Use of green materials to achieve high LEED rating

- Provide complete interface solution for internal and external needs whether external glazing/ACP/Clad support/brick or internal MEP/ Ceiling/internal clad/partitions/ water proofing/floor finishes or any other service needs

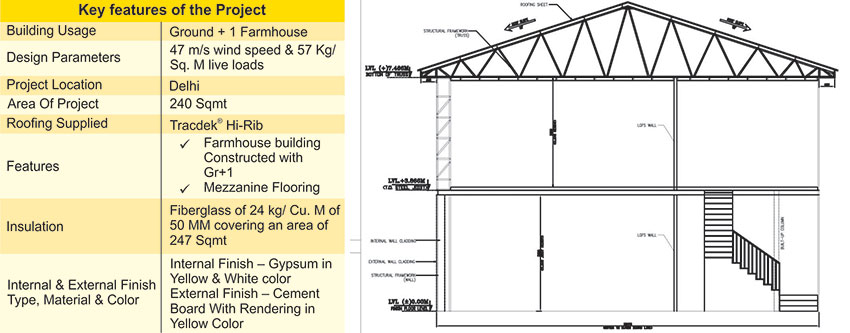

Project Spotlight: Interarch Light Building System Ground +1 Farmhouse, Delhi

Interarch Building Products India's leading turnkey solutions provider in Light Building Systems who has designed, engineered, and delivered a Gr+1 residential Farmhouse for its client Libra Buildwell Pvt. Ltd. recently.

The Gr+1 farmhouse has a mezzanine Floor with a 100 mm RCC slab on it. The roof of the farmhouse is flat. The finish of the Interior has high quality Dry Wall whereas the Exterior finish is Cement board with Rendering Plaster. Interarch Light Building systems are architecturally designed buildings customized to suit the requirements of the clients.