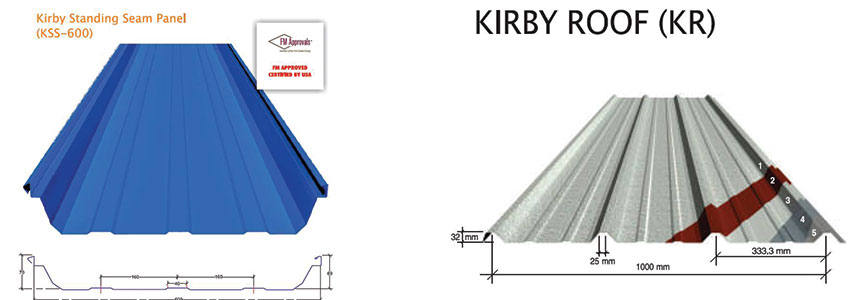

Kirby India provides two types of roofing products - KR Profile (Kirby Roof) and KSS-600 (Kirby Standing Seam). KR profile is provided both in bare and color galvalume forms in different thicknesses as per the customer's requirements. This roof is strong and cost effective and was specifically developed for roofing applications with the standard roof panel being 26 gauge with a minimum yield strength of 345 MPa. KR profile has 32 mm deep major ribs which taper in width from 79 mm to 25 mm and are spaced 333.3 mm or center. Additional minor stiffening ribs are spaced at 111.1 mm on center and are located between major ribs. Each panel covers an span of one meter area. The bearing leg design permits easier installation and maintenance, supports thicker layers and allows easier curvature for a visually appealing finish. The profile is prepared with a multi-layered coating system to ensure long life and optimum coating adherence.

This KSS-600 roofing system which was introduced by Kirby India in 2006 is the most specified standing seam roof system in the market as it comes with double lock standing seam ends, eliminates the risk of roof leakage at fasteners and side and end laps due to the concealed fastening system and provides excellent protection in all weather conditions. Kirby India is the first PEB manufacturer to achieve FM Global accreditation for its Standing Seam Roofing System (KSS-600). The various design features of this roofing system allows the company to offer the customers, a low pitch roofing as less as 2 degrees with fully sealed membrane roofing, even at high rainfall intensity areas. These are also available in very long length and can be rolled on-site where sheet lengths exceed the limit that are not possible to be delivered by road. This eliminates the need for end laps and consequently the potential for water ingress. This roof system is specifically designed to accommodate roof movement with daily and seasonal temperature changes. The system is attached to the building's structure with a special clip and tab assembly formed into the double-lock seam. Because the tab can move within the clip, the entire roof can expand and contract freely without sacrificing structural integrity.

This roofing system provides 100% leak proof buildings with faster installation. During installation, the 180-degree pre-roll formed edges of each roof panel are assembled and are further seamed by seaming machine, completing a full 360-degree seam. Inside the seam, a factory applied sealant eliminates the chance for even tiny capillary leaks. The KSS-600 roof system is available in 26 and 24 gauges aluminum/zinc or color coated steel panels.