"Serge Ferrari has always been the leader in development of technological products. In its quest for more innovative and advanced products, the company has recently come up with the latest innovation in the composite coated textiles industry and introduced a new fabric called PRECONTRAINT TX30 with design life of 30 years ++. For Serge Ferrari, Indian market has always been interesting and now with the new government's focus on Infrastructure development, we see better biz potential in India in coming years," says Country Manager-South Asia, Arun Madappallath, in an interview with Maria R.

Due to the versatility of tensile membrane, the tensile architecture is much sought after in India; what are the other reasons behind the increasing usage of tensile membrane in the country?

Textile Architecture embraces flexible membranes, allowing extensive architecture freedom, internal natural lighting and highlighting in both roof and façade areas.

Natural Light is an integral part of textile architecture. Its prime advantage is determining the visual comfort of users in which natural light is a structuring component of a project. In a growing number of countries, natural light supply is covered by official recommendations based on statutory texts. In France, the labour code (Article R. 235-2) states the buildings must be designed and laid out such that natural light can be used for lighting working rooms.

What are the new technological developments being witnessed recently in membrane industry and the roles of Serge Ferrari in elevating the industry to the next level?

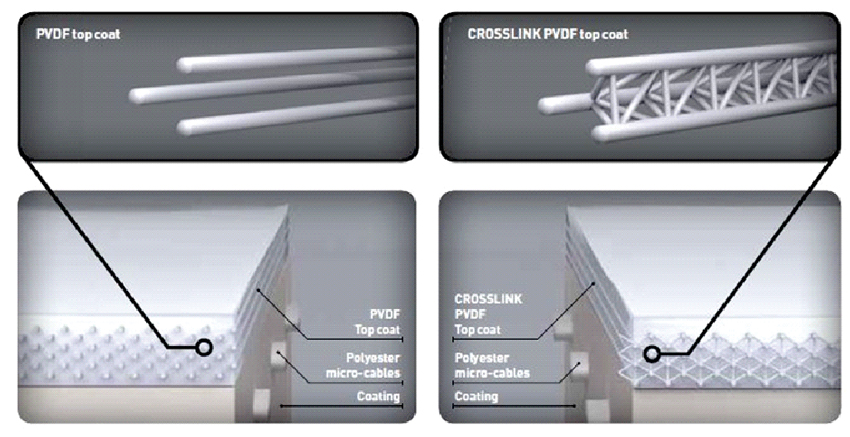

Serge Ferrari has always been the leader in development of new technological products and our innovation in the composite coated textiles industry is the introduction of NEW fabric for the tensile membrane applications: PRECONTRAINT TX30 with DESIGN LIFE 30 YEARS ++. Technological breakthrough of In-house development – CROSS LINK PVDF TOP COAT with a scientific back up Accelerated Weathering Protocol established by Photo Oxidation Specialists.

TX 30 = CROSSLINK PVDF FORMULA: The CROSSLINK formulation creates irreversible bond between molecular chains, in the sketch we express it in the form of a tridimensional network like Tri Di beam as an analogy to the building industry, as opposed to the standard PVDF whose molecules are rather in parallel to each other and not strongly bonded to each other. The tridimensional network provides high resistance to erosion and micro cracks. Cross linking is a chemical principle which applies for example to EXPOXY resin.

CROSSLINK Top coat formula

The CROSSLINK top coat formula generates irreversible links between molecular chains. This tridimensional network provides long term benefits:- higher resistance to photo oxidation and micro-cracks,

- stable and smoother surface to prevent dirt in-grain,

- easier and more efficient cleaning of the even surface.

Another important aspect is the warranty offered for this fabric.

- Standard Warranty for Precontraint TX30 is 20 Years for fabric only from Type II to Type IV – 100% fabric replacement warranty for the first 5 years and diminishing warranty after 5 years upto 20 years.

- A special 25 Years extended Warranty for excellence network by expertise and Inspection contract (every other year) and upon approval of warranty application – 100% warranty for first 10 years – replacement of fabric + fabrication of fabric + dismantling of fabric + erection of fabric and diminishing warranty after 10 years upto 25 years.

- Such warranty is first of its kind in the tensile membrane industry and this shows the confidence of our fabric performance in any extreme climatic conditions.

Today, architects are opting membrane for many different application areas such as sports facilities, airports, hotels, resorts, shopping malls, bus stands, parking areas etc. What are the latest innovative application areas ventured into for membrane architecture?

- Other market we intend to focus is the fabric covering for the Bio Energy industry applications such as composite silo & tanks/Water Purifications & Waste water treatment plants/Methanization units/Gas Storage. Main features of Serge Ferrari technical membrane for such application are Excellent gas impermeability (methane), Optimum UV resistance, excellent resistance to climatic damage, Flame retardancy treatment, several possibility finishes – Anti static (AS), Oil Resistance (OR), and Zero Emission (ZO).

Serge Ferrari pioneered the Precontraint Technology; could you please highlight the advantages of this patented technology?

Precontraint Technology – Base material of the fabric is HT PET (High Tenacity Polyester Yarn) Precontraint composite materials are tensioned in both directions (Warp/ Weft) during the coating process which ensures high dimensional stability, Low elongation under load, Low residual elongation, Uniform Biaxial behavior in both directions, No periodic re-tensioning required.

LONGER LIFE:

Better Top Coat Thickness on top of the Yarns: The effect of this pre-stressing is that the yarns of the fabric which normally are sinusoidal in shape, become extremely flat, and therefore allow a thicker PVC topcoat. It has been proved by independent studies that a thicker PVC topcoat enhances the life of the fabric substantially.DIMENSIONAL STABILITY:

The other benefit of Precontraint technology is that it makes the fabric highly dimensionally stable and has very little elongation under stress. Not only has it lower elongation but the residual elongation is also very little.

The above diagram depicts a test conducted on Precontraint and conventional fabrics. A weight of approx. 200 kg was attached to a Precontraint and a conventional fabric in the weft direction, for a period of 100 hours. The result shows that while the fabric was loaded the Precontraint fabric had a elongation of 0.8 % as compared to 2.5 % in case of a conventional fabric, which was more than 3 times higher. After the load is removed, Precontraint fabric comes back to nearly its original size, and residual elongation is observed to the extent of only 0.4% as against 1.4% in case of conventional fabric, which is again more than 3 times higher.

The above described elongation characteristics of conventional fabrics result in sagging of the fabric over a period of time due to constant exposure to dynamic wind loads. The fact that the residual elongation is much lower in case of Precontraint fabrics ensures that there is no sagging with passage of time due to pre-stress as well as the dynamic loads. This eliminates the need to re-tension the fabric periodically, which is a must in case of conventional fabrics. If they are not re-tensioned from time to time there could be a potential failure due to flapping or water ponding.

Above diagram shows Mechanical resistance stability of Precontraint fabric compared to Standard PVC/ PVDF fabrics.

What are the company's products available in the Indian market and their technical attributes?

Besides fabric for Light weight textile architecture, Serge Ferrari offers wide range of fabrics for the building industry:

TEXTILE FAÇADE:

Permanent Textile façade Solutions for your existing/new building. Advantage of using an exterior skin of mesh fabric as a facade is excellent solar protection properties and thus saving energy without cutting light properties. Architects can create 3D structures with lighting effects and printable options. The complete façade structure is light weight and easy to install.SOLAR PROTECTION:

Soltis Fabric for the internal & external roller blinds. Wide range of technical fabric for roller blinds with different openness factors from 3–14% depending on the light & solar properties requirements.Soltis Advanced range includes:

- Soltis ACTIV fabric with bactericide treatment on both sides eliminating 99.9% bacteria developed to contribute significantly to maintaining healthy environments in the most sensitive facilities and thus plays a key part in preventing infectious diseases and meets the most stringent requirements in terms of health and safety comfort.- Soltis AS fabric benefits of specific Anti Static Treatment which reduces significantly generation of static electricity and contributes efficiently to its dissipation.

INTERIOR TEXTILE ARCHITECTURE:

Fabric for Ceiling and wall covering – Batyline Aw A flexible composite fabric offers unique acoustic performance characteristics for such a thin light material. Fabric ceiling or wall covering with an air gap of 100 to 400 mm will give NRC value (Noise Reduction Coefficient) = 0.65.Efficient absorption throughout the sound frequency range including low frequency. This performance characteristic enables the requirements of multiple buildings to be met: Sports Hall, multipurpose halls, etc.

What efforts do you put to make people aware of applications and execution of tensile membrane in infra projects?

Serge Ferrari's global marketing strategy is to promote its products and work closely with Architects, Builders, Sports bodies, Government departments, Airport Authorities, Developers, etc .. and giving right fabric solutions depending on complexity of the projects. In India Specification team is dedicated for this activity in each region and now we have started exploring 2 tier cities as well to create awareness of the fabric solutions in different markets.