Wood polymer composite (WPC) is made from wood flour, rice/wheat/mustard husk, PVC resins, calcium carbonate and additives through a process called extrusion. Given its various properties, it is fast emerging as an alternate to real wood, PVC and other materials.

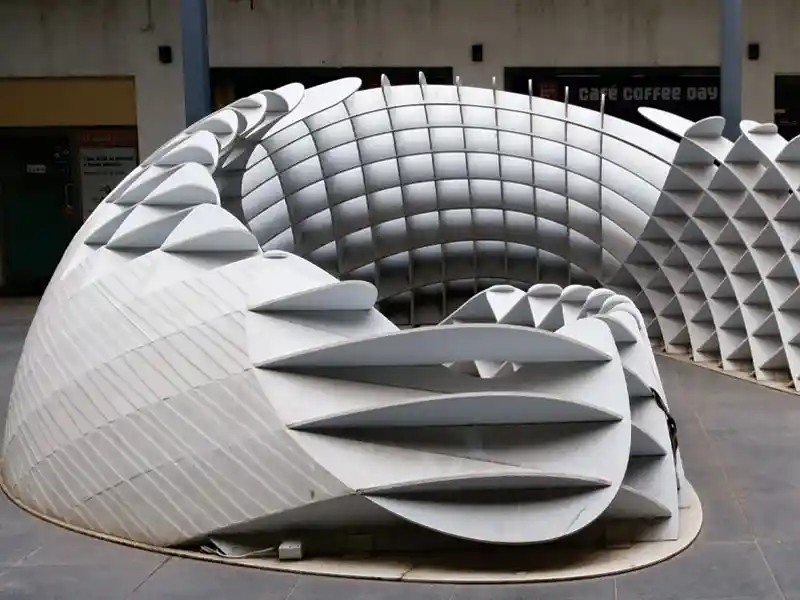

WPC application potential as a building material is unlimited, as it can be transformed and applied in endless forms and shapes, depending on the imagination and creativity of the designer

Deepankar Garg, Director, Alstone

What’s more, WPC can be used outdoors as well. This is because it is an inert material and does not react with any chemical or substance, and its appearance or performance does not degrade when it comes into contact with air, water, UV-rays or termites. It is fire-retardant and can be used as wall cladding and in wet areas. It is resistant to staining and scratches, plus, it has a high load-bearing strength and high impact resistance; and is 100% calibrated and 90 degree bendable.

WPC sheets come in various sizes and are nail-able/screw-able. They can be carved or cut into any form or shape, and painted with PU, Duco or melamine polish, or laminated with any type of mica or veneer. Being lightweight, the sheets are easy to transport and install.

Given these characteristics, it is not surprising that WPC is perceived as a substitute for plywood / MDF/ HDF / PVC boards. It provides a solution to the age-old issues of delamination, warping, bending, dampness, and termite infestation. Plus, it is green and sustainable as there is zero emission during its production.

| Properties | ALSTONE - WPC | Competing Materials |

| Raw Material | Made from wood flour, rice husk, PVC resins, calcium carbonate & additives | Made from thin layers of wood veneer that are glued together with adjacent layers |

| Water / Moisture | 100% proof | Low absorption |

| Water Dip Guarantee | Yes | No guarantee |

| Termite, Borer, Insect Proof | 100% proof | Affected |

| Integrity during fire | Does not aggravate fire | Supports and ignites fire |

| Wet Area Cladding | Recommended | Not recommended |

| Thermal Insulation | Yes | Yes |

| Flexural Strength | Very good flexibility | Flexible |

| Freeze Thaw Conditions | Pass | Not recommended |

| Impact on Environment Emission / NonToxic | Zero emission, non-toxic | The use of formaldehyde in plywood affects the eyes when kept in a go-down |

| Gluing & Lamination | Easily applicable | Easily applicable |

| Toughness & Breakability | Hard & Unbreakable | Hard and Breakable |

| Ease of Workability | Very good using normal carpenter tools | High workability |

| Shrinkage (under moist conditions) Hard & Unbreakable | No shrinkage | Shrink & Swell |

| Weight | Lightweight | Heavy |

| Transportation | Easy and quick | Heavier to load |

| Breakage on falling | No | No |

| Surface quality | Very smooth | Less smooth |

| Sound insulation | High | Lower |

| Calibration | Yes | No |

| Impact Resistance | High Impact resistance | High Impact resistance |

| Screwable & Nailable | Highly Screw-able & Nail-able | Lesser screw holding capacity & nail-ability |

| Suitable for Hardware Fixings | Yes | Yes |

Today, WPC has a market share of approximately 0.7% of the total plywood market. The number may not seem large, but for a product that has come into the market just a few years ago, this is a big achievement. It shows that it has been successful in breaking the traditional mindset of the customers to look for something better than plywood. And, in the near future, its scope for growth will only rise to make it the biggest and the most successful replacement of plywood. All this will be possible only if quality players come into the market and lay stress on marketing the product, as only a good quality product can bring in higher sales.

We have been creating awareness of WPC through our sales and marketing network and by organizing carpenter workshops, in-shop sessions, and presentations for the benefit of architects and interior designers with live demos, applications presentations and interactive workshops. We are also active in print and digital media and in various exhibitions.