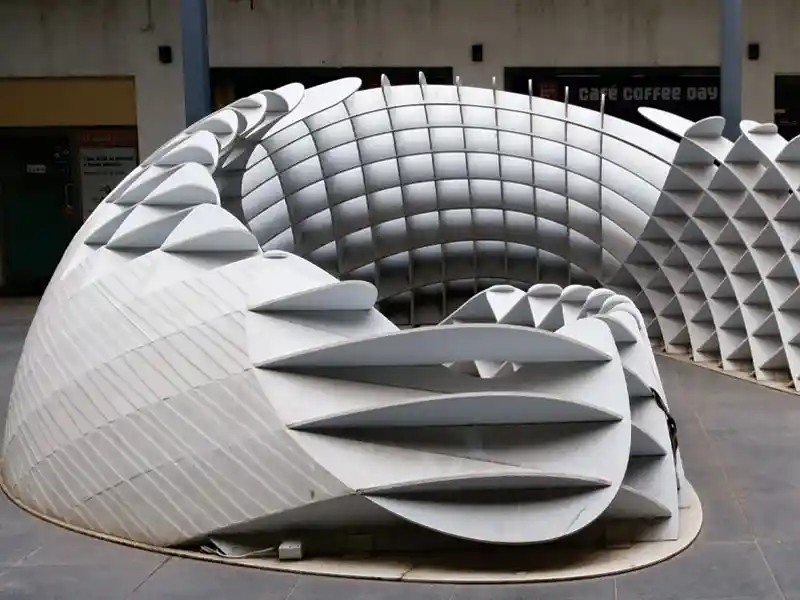

Formica, manufacturer of high-pressure laminates, has raised the bar with the launch of its next generation surfacing materials - Fenix and Deco Metal. These innovative materials offer a wide range of options and applications for creating luxurious interiors.

Deco Metal, on the other hand, is a real metal surface that can create unique, luxurious interiors with more than 100 decors, textures and brushed effects to choose from. Its durable, authentic metal finishes bond easily with surfaces.

The company continually strives to create innovative products that support sustainable design for a healthier environment. It selects materials with recycled content to reduce the impacts associated with the use of virgin materials. The recycled content in Formica® Laminate is determined in accordance with ISO Standard 14021.

Our primary focus is to educate consumers about the features and sustainable aspects of our next-gen surfacing materials Fenix and Deco Metal, including their durability, low maintenance, and the value they bring to interior spaces, so that they can make informed purchase decisions.

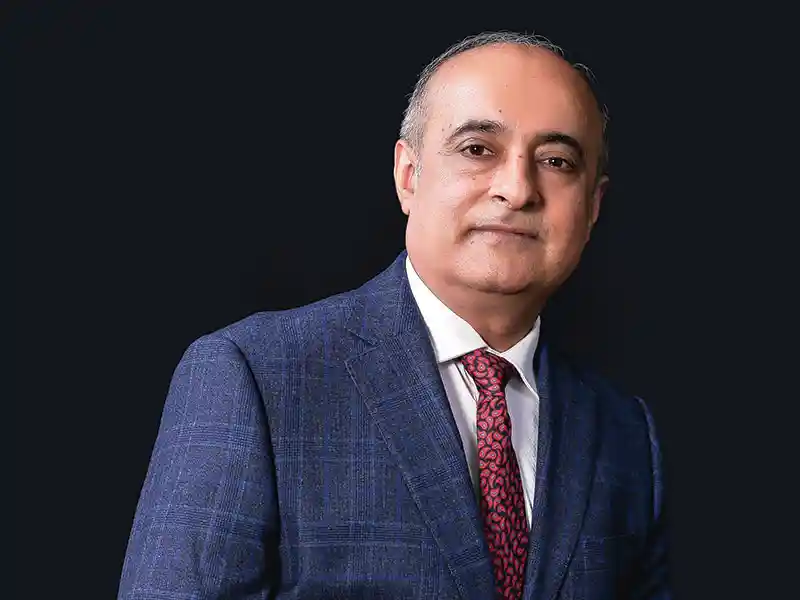

Ajay Khurana

As part of its goal to achieve net carbon neutrality by 2030, Formica Corporation aims for a midpoint benchmark of a 25% reduction of CO2 emissions and 10% reduction in primary energy demand by 2026. In addition, the company will pursue a 5% reduction of its water footprint in the next five years.

Formica has a fully automated manufacturing plant at Kalol, Gujarat, and a newly opened premium showroom in Delhi. The manufacturing unit is spread across 2,66,200 sq ft with facilities for HPHW, paper storage, surface treatments, core treatments, a resin lab, storage for phenol, formaldehyde, methanol, etc.