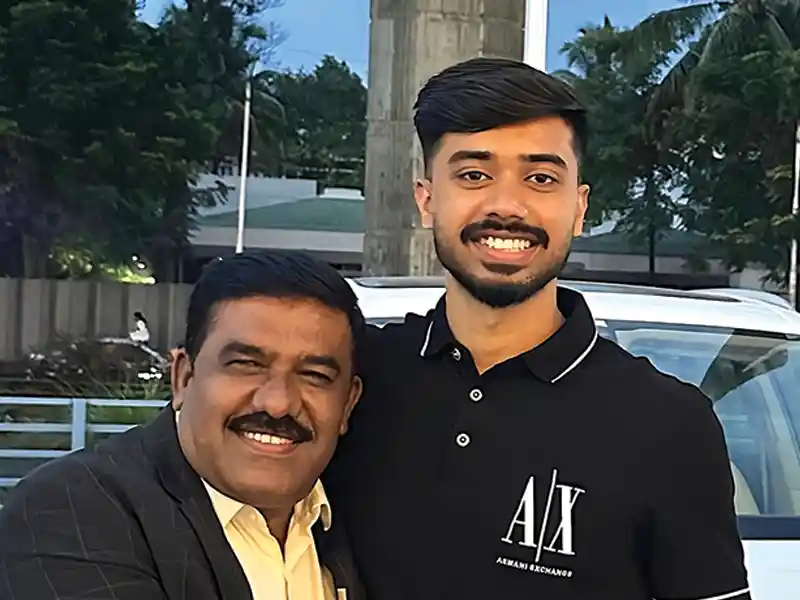

Mohan Kumar, CEO & Managing Director and Pradhyumna, Head – Operations, at Comfort Windows & Doors, present three of the most critical challenges in high-rise fenestration: installation, safety, and structural sturdiness.

The company is a leading manufacturer of high-quality uPVC and Aluminium Windows and Doors, backed by global technology partners Salamander (Germany), YKK AP (Japan), and Jindal-Domal Systems (India). It has a 30,000 sq. ft. state-of-the-art manufacturing plant and a 3,000 sq. ft. experience centre in Bengaluru which deliver premium, customizable products that meet international standards.

Over the years, we have continuously addressed three of the most critical challenges in high-rise fenestration: installation, safety, and structural sturdiness, through research-driven design, advanced engineering, and on-site innovation, with a focus on creating sustainable, energy-efficient fenestration solutions for both residential and commercial projects across India.

Installation: Installing fenestration systems at high elevations demands precision alignment, secure handling, and strict adherence to safety and quality standards. Common challenges include limited accessibility, slab-level variations, and maintaining airtight and watertight integrity under high wind conditions.

At Comfort, we address these through a modular installation system — where every window unit is prefabricated, factory-assembled, and performance-tested before dispatch. This approach minimizes on-site work and ensures uniform quality. Custom-engineered lifting mechanisms and bracket systems enable safe and accurate installation at height, reducing turnaround time while maintaining superior precision.

High-rise fenestration is not just about aesthetics; it’s about engineering innovation, user comfort, and sustainability. By combining European technology with Indian manufacturing excellence, we, at Comfort, are delivering superior façade and fenestration systems.

Safety Considerations: Safety in fenestration has two dimensions: occupant safety and installer safety. High-rise windows must withstand intense wind pressures and dynamic loads. Comfort Windows ensures compliance with EN and ASTM standards, integrating impact-resistant laminated glass, steel-reinforced profiles, and multi-point locking systems to enhance safety and durability.

For our installation teams, we implement harness-based anchoring systems, restricted work zones, and continuous supervision. Post-installation, non-destructive testing (NDT) verifies the strength and integrity of fixings and joints, ensuring long-term reliability and peace of mind.

Structural Strength and Sturdiness: High-rise structures expose fenestration to extreme environmental forces — from wind loads and thermal expansion to pressure differentials. Our engineering team employs Finite Element Analysis (FEA) and wind load simulations to determine optimal profile systems, glass combinations, and reinforcement thicknesses for each project.

Project: Assetz Canvas & Cove, Bengaluru

Profile System: Salamander Streamline 60 Series (Germany)

Glass Specification: Single-glazed, laminated Low-E safety glass

Wind Load Resistance: Tower-specific wind simulations were conducted for pressures up to 3.8 kPa, ensuring long-term stability.

Installation Logistics: Floor-wise sequential installation using modular frames eliminated on-site fabrication and reduced cycle time.

Quality Assurance: Each window underwent factory-based air, water, and structural testing as per EN 1026 / EN 12211 standards.

Outcome: The result was a high-performance fenestration system offering 45 dB sound insulation, superior thermal efficiency, and exceptional structural durability — showcasing Comfort’s commitment to precision engineering and sustainability.