| At a glance: | |

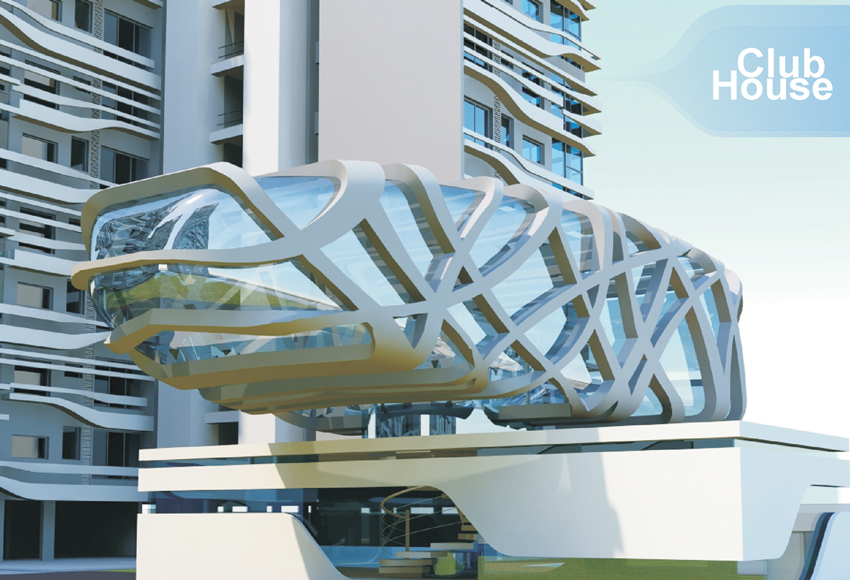

| Project: | Club House, Balaji Windpark, at Vaishnavdevi circle, Ahmedabad. |

| Form: | Shell like glass enclosure, complete glass 'gymnasium' |

| Glass Manufacturer & Supplier: | Marvel Glass Private Limited |

Shree Balaji Wind Park is a luxurious residential project developed by Shree Balaji Group and ideally located in the rapidly developing area of the city, Vaishnodevi Circle at SG Highway, Ahmedabad. Inspired by the Dubai and Spanish architectural design, the project consists of 6 towers each with 13 floors, state-of-the-art Pent Houses with Splash Pools and also a uniquely designed Club House ever built in the city.

Design: Shell like Glass Enclosure

The design of the moulded glass Club House is inspired by the Bird Nest or Beijing National Stadium, China. The architect has designed a classy shell form transparent and fully lit gymnasium which drives a message of engineering excellence and unparalleled commitment of the promoter to offer the best. Also, to give the form light feeling, the floor has been designed in glass.Curved and flat laminated glasses have been suspended from mild steel ribs, as outer skin of a complete enclosure, in the form of a shell. For added safety laminated glass floor has been provided to rest gym equipment, and as an actual glass floor inside the gym. The entire gym form is supported to a slab resting on a single column, on which a cyclic staircase is provided to access the gym.

Marvel Glass Private Limited, a leading architectural glass solutions provider was shortlisted to design and execute the complete glass form, including the glass specifications, fixing details and glass divisions, ensuring adequate structural strength with respect to live load and wind load, heat protection through diffused sunlight from the roof, glass alignment not allowing any water leakage, air vent cut-outs for hot air release, adequate air circulation inside the enclosure and structurally sound glass floor to absorb dead load as well as jumping load. Every aspect which includes, illustrated sketching, detailing of SS studs and aluminium flat supports for glass, steel templates for glass form and dimensioning, glass processing, glass installation, sealant application and overall aesthetics has been vendor’s responsibility.

Optimum Glass Engineering

Here many glasses are not only curved in different radius on individual axis but are also twisted in plane, while aligning with the adjacent glass which is again curved in different radii, but still aligned to the accuracy of millimeters to ensure butt joints which are leakage proof. Also, the curved safety glasses are made in factory and fitted individually at site, wherein for some glasses out of 4 edges, glass is structurally glazed on only 2 edges, although each panel weighs as high as 300 kgs. For each glass panel, individual steel template is made, cross braced to prevent distortion of template before it reaches the glass factory.Extremely efficient and skilled labor were involved to install these heavy glasses without allowing even a scratch on the surface, though hardly any platform was available to stand. As the glasses turn and enclose the form below the floor slab, the task of glass installation becomes even more difficult because at some places, there were hardly 6" gap between the glass panel and the slab which was not enough for someone to stand and install. Apart from the fact that each glass is customized and prone to extreme risk of scratches, edge chipping or cracking while installing…the given job has been successfully completed.

Meeting Challenges with Hi-tech Engineering

Not allowing heat build up on account of transparent glass cover all around, zero water penetration even with complex glass forms aligned with each other, capacity to sustain equipment and live load as a gym glass floor, viability to repair and replace any glass damaged during use, cleaning and maintenance of each glass panel both from inside and outside bearing the dusty weather of Ahmedabad…are some of the prominent challenges of this project. For each requirement independent features/technology innovation/engineering have been provided.

1) Preventing heat buildup: The roof glasses have been sand etched to cut light glare and to prevent the unwanted infra red radiation. Further 5 principal centrifugal turbo fans are provided to draw out hot air. Also, at the floor level air cooling duct is provided for supply of temperature controlled air to maintain ambient temperature inside at comfortable levels even at severely hot hours.

2) No water leakage: Glass fixing is facilitated using structural sealant. Further all exposed glass to glass joints have been impeccably matched and filled with weather sealant. Also, those grooves between glass panels not visible are sealed with dual protection of weather sealant.

3) Replacement of damaged glass panels: Made viable, as each individual glass panel is made in reference to a steel template while each panel is fitted in a manner in which it can be accessed and replaced.

4) Cleaning and maintenance of glasses: Structurally stable fitting has been incorporated to permit walking/access of safety laminated glasses from both outside and inside for cleaning using conventional methods.

Marvel Glass (www.marvelglass.com) undertook this challenging Club House project and completed it in 18 months, setting a landmark for Glass Engineering.