Almost 11-meter high glass fins support the façade of the exclusive lobby and create transparency and lightness

Construction board

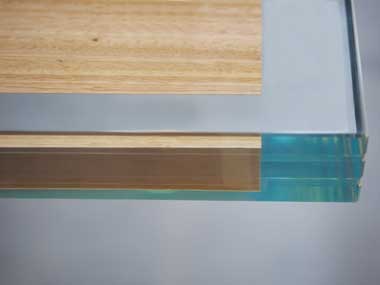

The wood veneers laminated in between the glass layers are perfectly parallel which is mandatory for the accurate and flawless appearance

Standard: green building (LEED gold)

Architects: SOM Skidmore, Owings & Merrill LPP, San Francisco, USA

Façade Contractor: Steel Encounters Inc, Salt Lake City, US

Completion: 09/2016

Sedak Scope

940m2 glass façade (lobby):

Wood-veneer laminates, 7.0 m high (3 x 12 mm)

57 glass units (façade) up to 10.9 m high (2 x 12 mm)

46 glass fins and beams up to 10.9 m high

Nothing less than the perfect symbiosis of glass and wood – is what the architects of Skidmore, Owings & Merrill LLP (SOM) wanted for a new 24-level office building in Salt Lake City, USA. The wood installed in the façade of the lobby “grows into” the 7 meter high glass elements. Sedak, specialised in oversize formats, to make this architectural vision a reality, developed a lamination technique that allows the German glass manufacturer to laminate real wood veneers in between the glass layers. Hence, the visual appearance is original and the wood permanently protected by the glass.

The architects had a clear vision of the office skyscraper’s lobby, which would have precious wood components that merge with 7 meter high glass elements. However, something like that had never been done before. The first suggestion was to use a photorealistic print, but was quickly rejected because the result of a print seemed not real enough to the architects. Therefore, the solution was to laminate real wood veneers in between the glass units’ layers. Then, integrating a natural, organic material in a glass unit without causing any damages during one of the production steps (e.g. tempering furnace), or losing visual quality almost sounded like a Herculean task. Thanks to a lot of experience and know-how in laminating glass, and a close cooperation of everybody involved, sedak found a way.

By letting the wood appear as if it was inserted within the glass, the building evolves its own effect. To manufacture such glass units, several challenges had to be met:

The raw material wood – eucalyptus in this case – is organic. It reacts to climatic changes like humidity and temperature and could shrink, become wavy, or burn. The lamination process (100° Celsius) had to be fine-tuned to be adjusted to the raw material.

The wood components meet the glass and appear going further into the laminates

Wood veneers are only available in upto 3 m. For the 7 m high glass units, horizontal joints were therefore necessary.

Maic Pannwitz, Executive Vice President, Sedak office, New Jersey

Steel Encounters Inc., Salt Lake City, US Wood in a glass unit. Eucalyptus is a relatively hard kind of wood, and is well suited for lamination

Steel Encounters Inc., Salt Lake City, US Wood in a glass unit. Eucalyptus is a relatively hard kind of wood, and is well suited for laminationFor logistics, the 7 m glass units were shipped in special wooden crates. In Salt Lake City, the temporary storage was located nearby which was perfect because they partly had to block traffic lanes for the transport to the site – but not only for our glass.