Elaborating further, Ajay Mohta said that the company has 20 strategically located state-of-the-art manufacturing units across India, large manufacturing capacities & wide range of products provide various options of customizations & helps in designing unique, cost-effective solutions matching customers' requirements. The company offers specialty products complying national & international standards such as BIS, ASTM, RöHS, UL94, FMVSS, and so on. This division is a part of the Supreme group, an acknowledged leader of India's Plastic Industry, handling over 2,30,000 tons of polymers annually with a turnover exceeding 4000 crores.

Adhering to sheer professionalism and devotion, we follow the philosophy of S.A.V.E. – Supreme Always Value Efficient. Every requirement is analyzed meticulously to select appropriate solutions and ensure smooth implementation. Whatever may be the value, our customers are assured of the best solution. Research and development form an integral part of our solutions to develop breakthrough products focused on energy efficiency and construction. Changing trends, shifting demands and new technologies drive our development of advanced solutions, he said

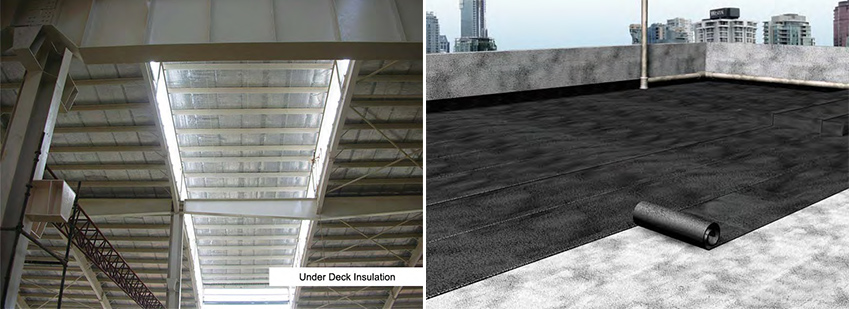

Supreme Industries strives hard to offer products matching customers' requirements and with these values and aspirations, we present our 'DURA and INSU range of products' especially for the waterproofing and under-deck insulation. India is a tropical country with diverse and unpredictable climatic conditions where some areas have hot tropical weather while others experience heavy monsoons. With the on set of monsoons problems like leakage, seepage in roofs, walls, basements, bathrooms become common and to save buildings from irreparable damage, Supreme offers DURAmembrane, a new offering in the portfolio of competent and DURAble products of the Construction Accessories Division. It is a new generation, cost effective solution for waterproofing of basements and roofs and is a versatile material, capable of retaining the dryness of concrete, masonry, metal and wood structures and is resistant to salts, alkalis, and most acids. It is offered as a quick and easy-to-apply system, ensuring hassle-free maximum productivity. Supreme is the only manufacturer of this type of waterproofing membrane in India which can be used for applications like - concrete roof waterproofing, basement waterproofing and also waterproofing of bathrooms & terrace gardens. DURAmembrane is not just used in new constructions but also for repairing the old structures.

It does not absorb water at all and its 'K' value does not deteriorate. Its inherent closed cell structure ensures truly and effective thermal insulation and waterproofing – virtually for a life time. It is a high performance, composite polymeric membrane which is durable and lightweight. It is non-deteriorating, puncture resistant and is available in length up-to 50 meters. About evaluation against bitumen based products – we all know that bitumen disintegrates after contact with water and over a period of time, it catches fungi and starts melting during summer thereby lowering its puncture resistant strength. The striking feature of DURAmembrane is that it has a very good puncture resistance of 199 N (Test method - ASTM E154: 1999) and being polymer based, it won't deteriorate for a long. This is a first of its kind of concrete roof and basement waterproofing product, specially designed to withstand the hot and humid Indian climatic conditions. Our membrane is going to solve problems and reduce huge losses arising out of water leakages. The entire construction industry will benefit from this product, he claimed.

Energy is the single largest operating expense and accounts for over $100 billion for commercial buildings every year. "With a view to improve efficiency and enable conservation of energy, the Thermal Insulation Division of Supreme provides top-of-the-line insulation solutions with its 'INSU' range of products" said Mr. Khanna. We offer customized solutions specifically for the insulation requirements of various industries with a sole purpose of improving efficiency thereby helping in conserving energy as well.

Khanna revealed that each of the products that we offer i.e. INSUshield – FR, closed cell chemically cross-linked polyethylene, INSUboard - Extruded polystyrene and INSUreflector - Radiant barrier are for the purpose of saving energy in different segments of the industry for different applications. In line with this, we offer 'INSUreflector'. It is a radiant heat reflective insulation material made of polyethylene air bubble film (ABF) laminated with aluminum foil on one or both sides. The bright surface of the aluminum foil reflects 96–99% infra-red radiation received by the surface of a heated slate roof. It protects the building from undesirable heat gain. The thin reflective foil having low emissivity and high reflectivity when installed with an air space restricts the transfer of far-infrared radiation. A material with low emissivity is a better radiant barrier.

Emissivity values range from 0–1. Any materials' Emissivity + Transmissivity + Reflectivity = 1. An opaque material has a Transmissivity of Zero, so its Emissivity equals one minus its Reflectivity. Aluminum foil is an excellent radiant barrier. Even though it is a good conductor of heat, but the mass of the foil being small, does not gain heat and effectively reduces its flow. As opposed to this theory, the conventional fibrous products which entrap air and retard the heat conduction. These types of products reduce conductive and radiant transfer at a rate determined by their thermal conductivity or 'R' value. In fact, with conventional products laying the reflective foil underneath, merely supports the product unlike the placement of the 'radiant barrier' directly below the roofing sheet to reflect radiant heat. It may however be noted that reduction in heat flow with installation of a radiant barrier is governed by a number of factors, such as ventilation rates, process performed inside the premises, ambient air temperature and humidity conditions, inclination of the roof, wind velocity and also the manner in which the radiant barrier system is installed. An important point to remember while installing a radiant barrier is that they must face an air space to perform effectively. It is easier to install a radiant barrier for a fresh construction than to go for a retrofit.

Wrapping up the conversation, Khanna claimed," We strongly recommend that all buildings where human effort is involved or where the process so requires, be insulated for a better working environment and ensuring increased productivity."