Please tell us about the evolution and progression of Pennar Industries Ltd. As part of Pennar Group with different business areas; how does Pennar entry into the PEB compliment group's diverse business area?

Pennar Industries was established in 1975 and has been involved in steel value added products. We have been steadily moving up the value chain from a steel company to a technology company. Pennar's strategy is geared to address the needs of three sectors of the Indian economy which, we believe, offer great growth opportunities in the future. They are the Infrastructure, Engineering and Automotive Industries. Pennar has been into the business of steel building components like purlins, sheeting, Interview deck panels etc for the past 35 years. PEB business is like a forward integration adding engineering and erection strength to offer complete steel buildings solutions for Industries, logistic parks, commercial buildings, stadiums, aircraft hangars, steel plants, power plants, and metro rail stations.

A word about your PEB vertical, its offerings and the quality standards followed to manufacture its products?

Since its start in 2010, PEBSL a subsidiary of Pennar Industries has been steadily growing. Our revenue was Rs.279 crores last year, now we are targeting to reach Rs.350 crores this year. In a short span of time, we bagged and executed orders for reputed companies like P&G, L&T, Ultratech, Volvo, Schindler, Toyota, Honda, Schneider Electric, Thermax, Dr Reddy's, My Home Cements, Reliance Industries etc. We have two brands, Prime Build and Value Build. While Prime Build is with Double Lok standing seam leak proof roofing system with technical collaboration with NCI, USA, Value Build is with normal trapezoidal sheeting for customers looking for economical solutions. We have state-of-the-art manufacturing facility at Sadashivpet, which is about 50 km from Hyderabad. We have dedicated customer service and project management teams to ensure timely completion of projects. We follow strict adherence to quality standards and obtained ISO 9001 certification. Our products are tested and certified by leading 3rd party agencies like DNV, TUV, Lloyds, SGS, BVQI etc.

What is the latest innovation and technological advancement being made by your company in the recent past? A word about PEBS Pennar cutting edge manufacturing unit and its customized brands.

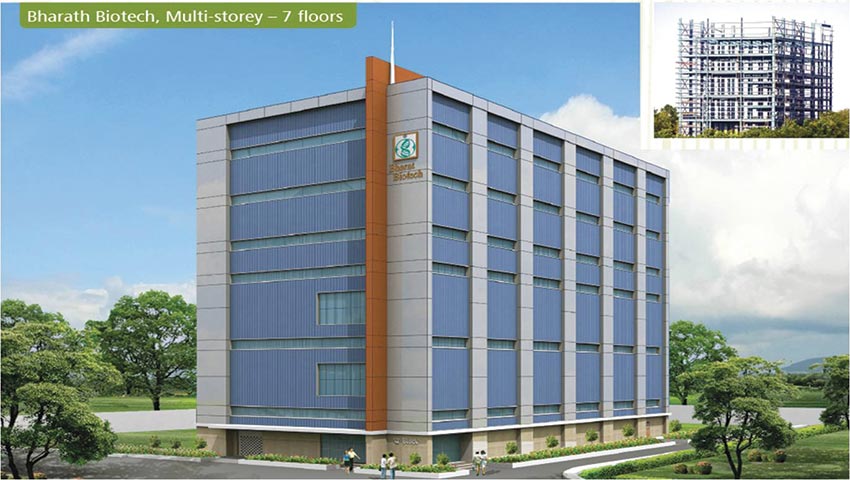

We have talented and experienced engineering team which is capable of providing the best economical solutions for highly complex structures as well. We have executed a project for Ultratech in Kotputli, in which, the clear span is 99 meters. No PEB company in India has ever executed such a large span building. Also we have executed 160 Meters wide building for Reliance Retail at Khurkumbh in which we used Double Lok roofing system using mobile roll former. We executed one project in Trichy with 200 MT capacity EOT cranes. We started venturing into multi-storied buildings and executed two buildings in Hyderabad, one with 7 floors and another with 14 floors.

Sustainability is shaping the building industry to an ever greater extent; how would your expertise in design and methodologies enable customers to improve upon the sustainability quotient of their buildings? How many LEED points do your products & systems fetch?

We follow strict adherence to design codes and practices. We have latest engineering updates and software to design highly complex buildings. Our designs are vetted by institutions like IIT Madras and IISC Bangalore on regular basis. Normally, our steel buildings fetch 15 to 20 LEED points and can gain more by adding some features like roofing system with high SRI index, roof top solar system, energy simulation etc. We have a specialized department to advise customers on Green Buildings. Our factory building is the first building in India to be rated under Gold category by IGBC.

What is your overview of developments, promotion and application of pre-engineered building system in India? How mature is the market of PEB in the country?

As infrastructure construction across the country is combining speed, economy, safety, strength and aesthetics at awe inspiring levels, steel structures, for quite some time a primary foundation element, have risen as complete solutions in construction projects for various structural requirements. In this era of competition, it is increasingly important to build more economical structures, which provide good integrated system performance. Steel is basically better suited for bigger, taller, and longer span and geometrically complex structures, as a result, steel is likely to be predominantly used for many years into the future. Engineers will need to develop suitable Codes and specifications for the purpose to meet the requirements of future generations. There is an increased need for more, for research and development, for innovative material and construction methodologies.

For the past 10 to 12 years, the focus of the world has shifted on India and China, the emerging super powers of the world. Any sector, whether it is manufacturing, logistics, energy, infrastructure, commercial, metro rail etc, is growing at a greater pace and all these sectors require high performance, economical and faster delivery steel buildings to run their operations. There is significant acceptability for PEB's in India and majority of consultants, architects, institutional customers etc are widely promoting PEB's in view of significant advantages compared to conventional buildings.

What factors are contributing to the growth of this sector in India and how do you see the growth trajectory in the coming years considering the current economic scenario?

Pre-engineered Building systems are not confined to industrial and warehousing but have gained diverse applications such as industrial power generation buildings, aviation hangars, cement boiler support structures, cold storage facilities, retail chains, distribution centres, stadiums, metro rail stations, outdoor fuel stations, highrise commercial buildings etc. Increased economy in civil engineering construction is achievable through higher strength steel, composite form of construction and improved materials therefore engineering community is more akin to use steel structural systems in the future and it is felt that this trend will continue.

Power plants, Steel plants and manufacturing industries predominantly use steel structures for buildings, support structures, conveyors, chimneys, workshops, warehouses, office buildings, car parks etc and the recent trend in India shows that the shift is towards pre-engineered structures which are shop fabricated rather than site fabrication.

Factors such as infrastructure development, retail chains, power plants, steel plants, airports, highrise buildings, metro rail projects etc are the key growth drivers in India. This industry is growing 15-20% every year.

What are the opportunities and challenges in the sectors?

The growth of PEB industry in India is directly linked to the economic situation. PEB concept was introduced in India in 2000 and there has been significant growth thereafter. Phenomenal economic growth rates over the past decade and its relatively unscathed emergence from the global financial crisis in 2008 led many to believe that the growth rates will be similar. However, over the last one year or so, an unhealthy economic and political environment has resulted in a screeching halt in decision making. This has delayed the implementation of reforms for spurring growth. With growth plummeting to 5.3% in last quarter, many are now questioning the India growth story. Obviously slower growth will adversely affect the PEB industry too. Retail chains are another high potential business opportunity for PEB companies. With the nod in Parliament for FDI's, there is significant potential for PEB's for retail chains and distribution centres.

The government of India has to create an investor-friendly atmosphere in the country by reducing the interest rates and the taxes & duties so that we can expect growth in industrial and warehousing sectors which will automatically lead to growth in PEB industry.

Also a broad campaign is required to increase the per capita consumption of steel which is around 40 kg in India compared to around 250 to 300 kg in developed countries like USA, China, Japan, Europe etc.

Though PEB has come a long way in the country, we still don't have any specific PEB design code. What organized players are doing to have IS code for PEB?

The IS code of 1984 was revised in 2007 based on the representation from PEB companies. Many of the recommendations were incorporated in the updated version of IS code. PEB companies have formed an association called PEBMA (Pre-engineered Buildings Manufacturers Association) and we are in the process of approaching BIS and INSDAG to formulate a code specific to PEB's.

A word about the after sales support and applicator's training provided by you?

We have a dedicated team for Customer Service and Project Management. We have excellent feedback about our after sales service and that's why we are getting repeat orders from reputed customers like Ultratech, L&T, Schindler, My Home Cements, Schneider Electric, Reliance, and Godrej etc. We conduct training programs periodically to our certified builders on erection methodologies, safety etc.

What are the designing & planning software used by your company?

For Engineering, we use MBS, STAAD PRO, AutoCAD, Tekla X Steel, 3D Max, Stru CAD etc and for Planning we use MS Projects and Primavera.