Mr. Arun Sharma

Mr. Christian Feldmann

aluplast Baroda Plant-ew Icon of the uPVC Industry in India.

What is your overview of the Indian Fenestration market? How important is this market for aluplast?

aluskin - Aluminium clip-on shells, Powdercoted in Any Color

AS: After all the experience we had in the past 10 years in India, we see the industry and the market on a good path. More people now understand the importance of good quality uPVC window/door frame material and also end users have started asking for that. We believe in the market's potential and so recently we have invested heavily. And every year we will continue to spend a multiple of the previous year's revenue to strengthen our footprint.

What are the advantages of aluplast uPVC doors and windows and significant challenges for marketing these products in India?

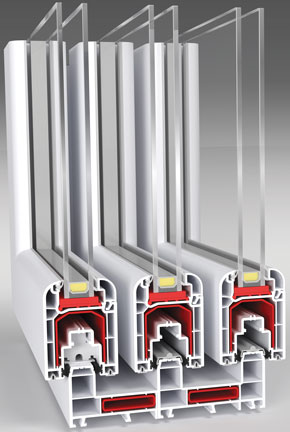

CFE: Our systems offer energy efficiency thanks to their far superior insulation compared to wooden windows or simple aluminum constructions. Also there is much less maintenance required with our products and especially for India's cities with their heavy traffic volume they provide great sound insulation. It's not so difficult, usually only 3 questions are enough to understand the quality of a uPVC window system: 1. Are you using lead free raw material?, 2. Is the uPVC raw material certified for high UV radiation?" and 3. "Are all gaskets coextruded?. And the company should be able to show the test certificates from renowned institutes to prove these points as well. That's it.

Multisliding for Elegant Sliding Door Solutions

AS: aluplast is offering the widest product range in the market. As we are getting directly served by aluplast Germany, we can combine both, locally manufactured products which are in line with the local market's needs as well as systems which are part of the German product portfolio. In that way, we can offer a great range from simple sliding systems to high end lift-and-slide solutions.

- Our MultiSliding system, the best-selling sliding door option in the Indian market, offers a 3-chamber profile for insulation and can carry glazing units up to 33mm.

- Our Ideal 2000 range is a rubber sealed system which is the best used for tilt and turn as well as casement windows and doors as well as french doors, tilt and slide and fold and slide systems of course also.

- aluplast initiated the Monorail concept two years ago very successfully in India and we are very proud of it and other profile producer are following. Again, aluplast is a step ahead and we also launched our monorail door system, which is available since beginning of this year, and will bring new solutions especially for projects and multi-storage buildings.

- We see increasing demand for hybrid solutions, i.e. uPVC windows which are covered on the outside with a powder coated aluminum shell. This combination offers an architect both, excellent insulation along with unmatched color options for the exterior.

Could you please brief us about your strategic partnership with Mantralaya Impex Pvt. Ltd (MIPL) and its brand ECUBE WINDOORS? What is the objective of this joint venture?

CFE: This venture is another innovative collaboration. aluplast is a family owned company and we are always looking for partners which are in line with our idea of commitment and have a similar strategic focus as we have. This we found in our partner Mantralaya and so we combined our technical knowledge and their market experience.

What is the status of your Gujarat plant and product to be rolled out from there in the initial stage?

Monorail for Smart Sliding Window and Door Solutions

We are now an integrated part of the extrusion network of aluplast which means that our Indian extrusions are also supplied back to Germany. It shows that our Indian products'quality is in line with the aluplast quality standard worldwide. In order to ensure this, we have invested in the best machinery and tools and anyone is invited to see for themselves in Baroda.

What's more, our Baroda plant will also be our service hub. Along with our extrusion, we will start lamination of our profiles in various colors in April this year. The technical center which we have established in Baroda alongside our extrusion facilities, equipped with German and Italian uPVC window making machines, is operative. Here, we are planning to offer trainings for the teams of our business partners in window fabrication and related topics on a weekly basis. We are proud to be able to contribute to the skill development of the Indian window sector in this way.

I would like to mention here that to support the aluplast India Team at the plant in a best way possible, Mr. Feldmann himself has shifted to Vadodara, Gujarat with his family.

Although Indian consumers have developed a strong inclination towards quality, but they still are price sensitive. How do you synergize the cost-quality proposition?

CFE: aluplast will never be the cheapest, one that's for sure and that's also not our focus to be honest. We see ourselves as a system provider, especially for technically complex solutions. There is a demand for better quality and also the willingness to spend more is increasing. Pricewise it is sometimes tough, I agree. However, the international product portfolio of aluplast offers many possibilities to choose from which gives us some liberty. But one thing for sure, the quality of our systems will remain the same, whether they are produced in India or Internationally. There we will never compromise with.

What is your view on the importance of Indian standards for uPVC doors and windows?

Ideal2000 for In-and Outward Openable Window and Door Solutions

What are the sales services you are providing?

CFE: You are raising a very good question. After-sales service is one of the most common areas of struggle in India where many mistakes happen. aluplast has counter acted this. We are taking care of every individual complaint by end users. Even if the profiles are not causing the trouble but maybe the hardware or the installation is, for which, technically, we are not liable. We have to create trust in the market and people are very happy to see a performance like that.

What is aluplast's plan to participate in the forthcoming Frontale 2016? How will your participation in this mega show help to promote your products and services, adding new business opportunities?

AS: The Frontale 2016 in Nuremberg/Germany is our mega event this year.Under the slogan "The window to the future" we will present comprehensive, future-proof solutions. Comprehensive, because the aluplast booth will not only be about products and innovations, but also about the support aluplast provides to our window fabricators in other fields such as marketing and sales. However, future-proof solutions are the key to everything and at aluplast, we do not take this lightly but ensure future-proof products following a process that has generated our successes for years, effective innovation management.