"We feel that the market for pre-engineered steel construction is growing exponentially in India with consumers opting for new-age technologies for quality and speedy construction. Moreover, due to the unmatched advantages of PEB over conventional building technologies, the market is experiencing a demand shift to new applications such as construction of airports, multi-story buildings, stadiums, Metro Stations etc. which undoubtedly shows a promising future ahead of PEB industry in the country," avers Mr Gautam Suri - Founder Director of Interarch in an interview with Maria R.

What is your overview of developments of pre-engineered building system in India? How mature is the market of PEB in the country?

The journey of Pre-Engineered Buildings in India has been remarkable in such a short span of time. Sectors such as automotive, power, logistics, Pharma, FMCG, and retail provide huge growth opportunity for PEB in India. It is said that the PEB industry is still in its infancy but, over the last six years, there has been a phenomenal growth in this sector due to increasing awareness amongst consultants and customers. Pre-engineered building sector has started getting its due credit as a favorable alternative construction methodology in India today. There is undoubtedly, a very promising future for this sector in the coming years.

The Indian pre-engineered consecution market is now experiencing a demand shift to new applications due to infrastructure development in the country like airports, multi-story buildings, stadiums, Metro Stations etc. The country will see increased economic growth, and the removal of barriers to foreign investment will "spur demand for construction" over the coming few years. There is undoubtedly, a very promising future for this sector in the coming years.

How do you foresee Interarch's business growth in coming years with government's plans to construct 100 smart cities and the industrial corridors? What is your strategy to be ahead of all?

The pace of infrastructure development in the country is going to accelerate in years to come. Stemming from the Pre-engineered buildings industry, what is taking shape is the application of pre-engineered construction to new Heavy Engineering and larger Infrastructure projects which is the next in line for development in the country. Projects like 100 smart cities, new no frill airports at various cities, International terminals, Industry corridors, power plants, ports etc. require heavy steel structures and a different approach in comparison to Pre-engineered buildings. The opportunity in these sectors is huge and we are all geared up.

PEBs are not just confined to industrial, logistics, power generation buildings, and aviation hangers, but have also gained diverse applications in multi-storied complexes, and more importantly in metro rail projects and stadiums. How do you see biz opportunities from these sectors?

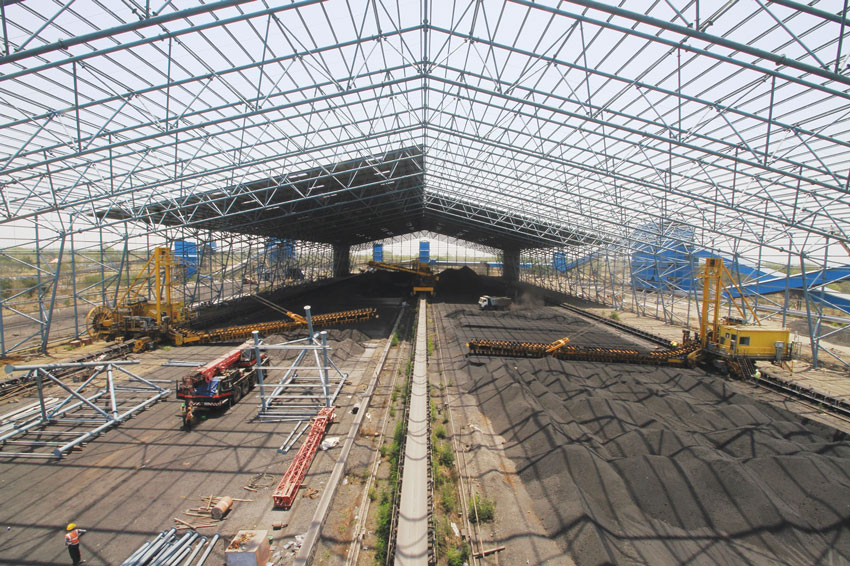

Interarch has been providing innovative solutions to Indian market right from inception in 1984 and even today many innovative solutions have been accomplished by Interarch in recent years right from Multi-storey buildings to a 99.8 M Clear-Span to installation of 125 MT crane at a height of 22 M to delivering a 33 M long bridge girder for Delhi Metro.

Interarch is in the process of delivering first Ground +7 Multi-Storey Hospital Building for Fortis Healtcare in Bangalore; a 99.8 M clear span building, largest in India for Ultratech Cement ltd in Raipur; G+ 10 multi-level process structure for CP India in Maharashtra, and G + 6 multistory process plants buildings for HUL in multiple locations.

Pre-Engineered steel construction market has been growing in double figure year-on-year since the last few years; also it would certainly not be an exaggeration if we say the industry is catching-up very rapidly. In fact, pre-engineered building sector has started getting its due credit as a favorable alternative construction methodology in India today.

Last three years have been quite tough for PEB sector due to economic slowdown. How has Interarch been faring in this difficult condition?

We have been able to sail through the tough times because of our strong financial backing and solid management systems in place. Last few years, we have consolidation our operations and penetrated into new sectors; opening new applications for steel buildings in India such as cement industry, multi-storey buildings and power sector.

India is a cost sensitive market and the initial higher cost barrier is one of the reasons for lower uptake of PEB. Going forward, do you feel PEB construction could be made more affordable and would be preferred for low cost housing option?

The higher cost barrier is just a preconceived perception of people who have never used pre-Engineered buildings. It has been witnessed that now more customers & companies are realizing that low cost does not always mean better and superior quality. Pre –Engineered steel buildings have unmatched advantages over a concrete building in this case some of the factor which may influence are:

- Construction time is reduced by at-most 30-40 % which gives early occupancy and early ROI

- Large clear span structures upto 100 m & Clear height of up to 30 m are possible and mezzanine floors can be constructed which help in maximum usage of space and hence provide better utilization of money spent every Sq.Ft

- Less energy consumption due to natural lighting available hence less electricity bill

- Easy to construct and easy to expand in future when required without disturbing existing operations

- Fire and earth quake resistant –Very low or negligible maintenance cost which again saves in overall cost of the building

- Cheaper below ground due to lighter foundations

We feel the market for pre-engineered steel construction is growing exponentially in India with consumers opting for new-age technologies as well as the need for fast construction. All sectors in India are expanding in terms of business and more companies are coming to India which gives pre-engineered steel sector huge potential to grow. We are confident that consumers are getting ahead of the price sensitive market and are considering reputed companies to provide better and quality product.

Do you feel that industrial building customers have sufficient awareness about PEBs as the optimum building technology for their applications? How the lack of awareness amongst the building owners is helping substandard buildings being offered to them? Does your company undertake programs to increase the awareness about PEBs?

Leading customers realise that the PEB supplier has a major role in planning. This separates the small timers from the large players in the market

At Interarch we take many initiate to educate customers and key stake holders:

- Release months newsletter and emails campaigns to relevant Target audience.

- Interarch executes Building Innovators forum for knowledge leaders and innovators of the steel buildings community of India at various cities across the year. Interarch Building Innovators aims to bring together the best minds in the country to commemorate modern Indian engineering and infrastructure development using steel .

- Interarch conducts Young Builder Program at Engineering and architecture college to give an insight and educates Young Architects & Engineers about the Indian Pre-Engineered Steel Industry, various applications & nomenclature of Metal buildings

- Also we participate in many seminars and exhibitions and educate the visitors.

We are working with BIS currently to incorporate something on the above lines

What support and policy-push are you expecting from the government to have more conducive environment for the use of PEB?

We are happy with government current initative like Make in India campaign, allocation of funds for new infra projects like metro, 100 cities, hospitals etc.

The GST regime will make the use more cost effective as the customer will be able to utilize the input credit from a manufactured building.

What is Interarch's strength and USP? A word about your after sales support and applicator's training program? Could you please tell us about few of Interarch recently executed projects in India?

Interarch is today one of India's leading turnkey pre-engineered metal building & steel construction companies and has been in the business of metal building products for the last 30 years. Interarch expertise in integrated design, manufacturing & supply, and turnkey execution of pre-engineered metal buildings and steel construction solutions.

Interarch's capabilities extend all over India with our nation wide sales and project support offices spread over 20 locations and serviced by three manufacturing units in India at Pantnagar & Kichha (Uttarakhand) and Sriperumbudur, Chennai with a combined capacity of over 1,20,000 MT per annum of steel buildings and over 40,000 MT per annum for its Tracdek Roof & Wall systems.

We at Interach follow a very transparent system; always work towards customer satisfaction and on-time projects delivery. We are the only company which invites customers to plants for inspection of raw material as well as finished goods and has un-matched quality control setup in manufacturing facilities

Interarch is the only company in India to provide turnkey solutions with a certified builder's network of more than 60 certified builders across India. We ensure quality and timely delivery at site through:

- Quarterly training sessions to site engineers and certified builders

- Technological upgradation know-how and half-yearly rating system

- We practice stringent safety rules and international standard and propagate Zero accident at our sites