Window glass insulation is more efficient, paints and coatings hold better and brighter for longer periods, flooring finishes retain their sheen and the exteriors are water-, mold- resistant too. And this is just around the house. Sealant technology has extended the life of heritage structures, increased scope for architectural design by adding flexibility and durability to materials and joints. There is added safety by coating glass facades to make them impact resistant. Insulation properties are enhanced too without added maintenance effort.

"Sealants and Adhesives have played a vital role in the construction industry for the last 30-40 years. The performance of all these sealants can be even seen today with the kind of durability the old structures possess," corroborates Mr Vidyut N. Acharya, Director, Associated Chemicals. Associated Chemicals are known by their Acecoats brand of Construction Chemicals.

Holding it together

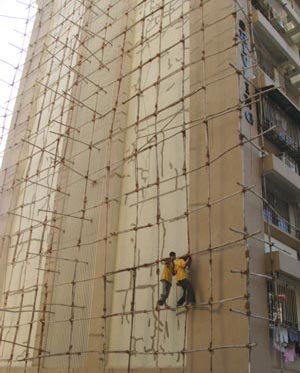

"Silicone sealants play a major role, simply because of their outstanding properties, their easy handling, and their durability. They can be used for sealing windows, gaps, and all kinds of constructive joints, so they are an integral part of any façade. Silicone sealants meet the high specifications of this application through their excellent property profile – excellent weatherability, UV-, and aging resistance, very good movement capability and long-term functionality. They also exhibit outstanding adhesive strength to both non-porous and porous substrates," adds Mr Srinivasan.

Promoting fenestration

Glass facades are increasingly spotted across the country's landscape. Fenestration is a design and structural element adding value to building elevations. It needs much attention at the construction stage to ensure that insulation from sound, thermal variation, dust and moisture is at high efficiency levels. This is achieved significantly with the inclusion of appropriate sealant products. Recognizing this need, Construction Chemical companies have developed product ranges of adhesives and sealants specific to glass construction applications. "Fenestration includes windows and curtain walls as well as accessories, but also installation, glazing, sun screens, etc.

"The window sector involves several ways of sealing: connection joints between the window frame and the masonry; sealing between glass and frame; sealing and bonding of aluminum windowsills, and profiled glazing. The silicone sealant in the window area has to endure extreme load at all times. This includes substantial temperature changes, variable weather conditions such as sunshine, rain, snow and frost, wind pressure and considerable movements between structural elements made of different materials. The sealant therefore combines the functions of a weatherseal, a seal and a bond. An ideal combination of useful properties makes silicone sealants suitable for all key applications," avers Mr Srinivasan.

Energy optimization

Builders and their clients are taking on their share of energy conservation to save on the costs to their wallet and that of the environment. "Buildings contribute approximately 40% to overall energy consumption; however a properly designed and engineered façade can enable considerable decrease in energy consumption. A well-engineered façade, together with the right usage of silicone sealants and the appropriate selection of glass provides thermal insulation and water proofing which helps reduce energy consumption in buildings. In addition to providing the structural strength to adhere the glass to the substrate, the silicone sealant also provides the flexibility to architects to help design buildings which are aesthetically pleasant and also compliant with safety and sustainability norms" asserts Mr Padmadas Nair.

Getting the best service

The key to getting the best service from sealant application and products is considering factors like wind pressures and thermal stresses at the construction stage itself. Choosing the most suitable product is equally important. "Only high quality silicone sealants offer the adhesion and flexibility profile needed for reliable, long-term protection," cautions Mr Srinivasan. Appropriate application procedure, often a simple one, is equally important. "Most important aspect for any product to stick on to a surface is the surface preparation. In order for the bonding to be strong between the surface and the sealant, the surface needs to be thoroughly prepared. Many of the surfaces which are dirty or greasy would hamper the bonding. Therefore, surface preparation is a must for the durability of a sealant. Manufacturers also offer supply and apply service, where for a specialized application or where the product is expensive and the customer does not want to take a risk by adopting a DIY option, a team of authorized and trained applicators are dispatched to execute the work. This service is not offered at a premium rate and is affordable to majority of customers" adds Mr Acharya.

"High attention for detail and finishing are the key to enjoy aesthetics everyday especially with the ever increasing lifestyle expectations. Finishing at 80-90% level is not acceptable. The aim is to strive for 100% perfect finishing and here lies a huge opportunity," quotes Mr Amit Malhotra. McCoy Soudal's McAademy training application center for sealants, adhesives and foams targets training applicants of sealants and foams to deliver perfect finishing with these products.

Help is at hand with manufacturers setting up customer connects with service and educational initiatives. "In order to enable the construction industry to better address concerns around safety and durability, Dow Corning has recently introduced a program called Quality Bond. This is an innovative membership/ certification program for various stakeholders in the construction and infrastructure market, the objective of this program is to ensure world-class standards for structural glazing and insulating glass manufacturers," according to Mr Padmadas Nair.

How simple is it?

Product simplicity is also offered in the construction process as Mr Srinivasan tells us. "Silicone sealants for construction purposes are room temperature, one-component vulcanizing, so called RTV-1 systems. This means that they cure directly in the joint, once applied. Curing (drying) is triggered by atmospheric humidity. Basically, there are four different curing systems: acidic, neutral, basic, and aqueous. Each type is based on a different crosslinker. Acidic systems release acetic acid upon curing; neutral systems alcohol or oxime; alkalines create amines; and aqueous systems release water while curing. All silicone sealants provide good to very good adhesion to glass. Due to their outstanding adhesion properties, neutral curing sealants are usually preferred, when substrates like metal (e.g. aluminum frames) or plastic (e.g. PVC) are involved."

Just another friendly way to make sealants a part of your daily environment!