Kaushik Nag, Marketing, Industrial Adhesives & Tapes Division, 3M India Limited

One specific, intended use for this tape is 'roof-to-trim' sealing and sealing around roof top mechanical fasteners on commercial vehicles to eliminate large quantities of liquid sealants. The leakage in roof joints of commercial vehicles is caused by corrosion of welded joints, loose or corroded screws and cracks in the sealant joints.

In an actual application in Japan, on the top of a commercial truck, 3M™ Extreme Sealing Tape 4412N was examined after five years in use, and it was found that the strength and performance were intact. Accelerated aging was also conducted at the 3M Weathering Resource Center in St. Paul, MN as well as actual outdoor weathering conducted in both Arizona and Florida. In India too, we have successful application on top of commercial fleets over the last five years and the numbers are increasing.

The acrylic adhesive used in the 3M™ Extreme Sealing Tape is manufactured from the same technology platform as the 3M™ VHB™ Tapes. The 3M™ VHB™ tapes have been used very successfully for both indoor and outdoor applications for over 30 years.

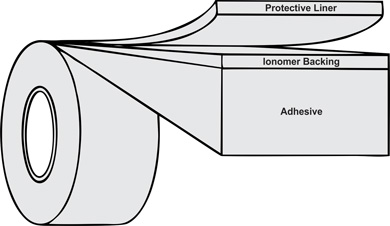

This highly conformable single-sided acrylic tape with high performance ionomer backing has many takers in another growing segment of Pre Engineered Buildings in India. It has now become a widely accepted product for turbo vent joint sealing on the PEB roof tops where conventional sealants barely provide a long term sealing solution. Being translucent, 3M™ Extreme Sealing Tape is an invisible sealing solution on glass canopies and skylights.

The application technique of 3M™ Extreme Sealing Tape is extremely simple and does not require sophisticated tools or caulk guns. After a proper surface cleaning, substrates having high surface energy like bare aluminium or bare stainless steel, are receptive to the adhesive tape bonding. Once bonded, the top protective liner is peeled off and the tape rolled on to the substrate with a simple squeeze or rubber roller. Substrates that do not have high surface energy (for e.g. some painted metals and most plastics) needs to be treated with an adhesion promoter to obtain maximum adhesive bond.

From roof tops of buildings and commercial containers to underground cable enclosures, 3M™ Extreme Sealing Tape provides a durable seal through heat, cold, and weather without cracking or edge lifting. Over time more extreme advantages become obvious.