Manish Poddar - CEO, PIC Sapleston Stone

We first introduced hand-made cobbles from quarry waste, converting waste into valuable exports, and significantly contributing to the country’s foreign exchange earnings. This initiative showcased the potential for innovative approaches to natural stone utilization. A pivotal moment came in 2007 at the Global Stone Technology Forum in Jaipur, where renowned architect Hafeez Contractor emphasized the need for a real stone veneer suitable for various applications. This concept inspired me to develop the Sapleston stone veneer.

Interior partition wall in veneer & Exterior wall cladding in stone veneer

Interior partition wall in veneer & Exterior wall cladding in stone veneerSapleston stone veneer is made from various natural stones. It uses thin layers of natural stone instead of full-depth slabs to offer a sustainable alternative to natural stone – a fast depleting and valuable resource. It has a thickness of 1-2mm, offers flexibility, and comes in various sizes and colors, making it suitable for a wide range of interior and exterior applications. It comes in various panel sizes ranging from 150 x 600 mm to sheet sizes of 600 x 300 mm and 3050 x 1220 mm. It is available in about 31 different colours and patterns.

As an environmentally friendly product, Sapleston is a must-have for architects, interior designers, and real estate developers looking to create green homes and offices.

Manish Poddar - CEO

Advantages of Sapleston Stone Veneer

Sapleston Stone Veneer, designed to maximize utilization of natural stone resources, addresses the challenges posed by traditional stone use and offers numerous benefits:Conservation of Natural Stone: Stone veneer uses thin layers of natural stone, reducing the amount extracted from quarries and conserving these resources.

Reduced Waste: Production of stone veneer generates less waste during production and installation compared to traditional stone construction methods.

Energy Efficiency: The lighter weight and thinner profile of stone veneer reduce energy requirements for production, processing, and transportation.

Sustainable Construction: Stone veneer supports sustainable construction practices by minimizing the environmental impact of building projects.

Durability: The long-lasting nature of stone veneer ensures efficient use, reducing the need for frequent replacements or repairs.

Versatility: Stone veneer can be applied in various settings, maximizing use of natural stone resources.

Reduced Carbon Footprint: Lighter weight leads to fewer greenhouse gas emissions during production and transportation.

Efficient Resource Use: Optimizes the use of natural stone resources, minimizing waste and reducing demand for new quarrying.

Aesthetic Appeal: Offers the appearance of natural stone without requiring large quantities, appealing to environmentally conscious builders and architects.

Cost-Effectiveness: Often more affordable than traditional stone methods, making it a viable option for budget-conscious projects.

Weight Reduction: Significantly lighter, making it easier to handle and install.

Increased Durability: More resistant to cracking and breaking due to its thin profile and attached backing material.

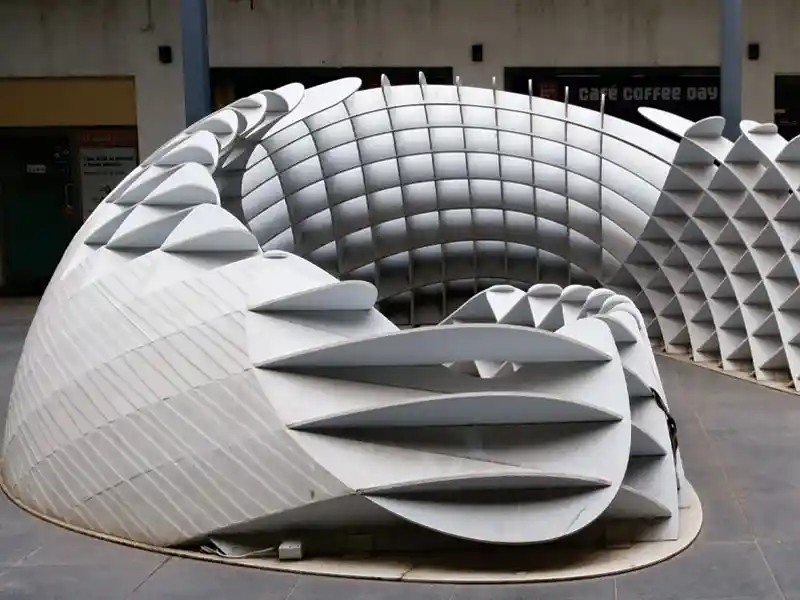

Versatility: Can be used on curved or irregular surfaces, unlike thicker slabs.

Enhanced Safety: Reduces risk of injury associated with heavy stone slabs.

Faster Installation: Generally quicker to install compared to traditional methods.

Improved Thermal Performance: Provides better insulation and thermal mass benefits.

Design Flexibility: Allows for more creative design options due to its thin profile and flexibility.

Environmental Benefits: Reduces the amount of natural stone extracted, processed, and transported, leading to a lower carbon footprint.

For further details, please contact: +91-98101 75175