Creative cluster

Building D(emountable) is situated on the site of a historic, monumental building complex in the center of Dutch city Delft. This site is owned by cepezed, an agency with expertise in the development, design, and realization of buildings.

After acquiring the complex in 2012, cepezed transformed the monumental buildings into a creative cluster with housing for various companies. The only non-monumental building on site was in poor condition. It has now made way for the new construction of Building D(emountable) and is intended for companies in the creative industry.

Circular prototype

The Netherlands has set itself the goal of rendering all construction activities fully circular by 2050. cepezed has a long reputation for modular and demountable design and construction. Moreover, director Menno Rubbens of cepezed is part of the national program committee to achieve the national circularity goals. Building D(emountable) also had to become an example project on cepezed’s own grounds; by showing the way in which they approach circular construction and the way in which one can make buildings that can later donate to other projects or even be reused elsewhere in their entirety.

Lightweight, flexible, and gas-free

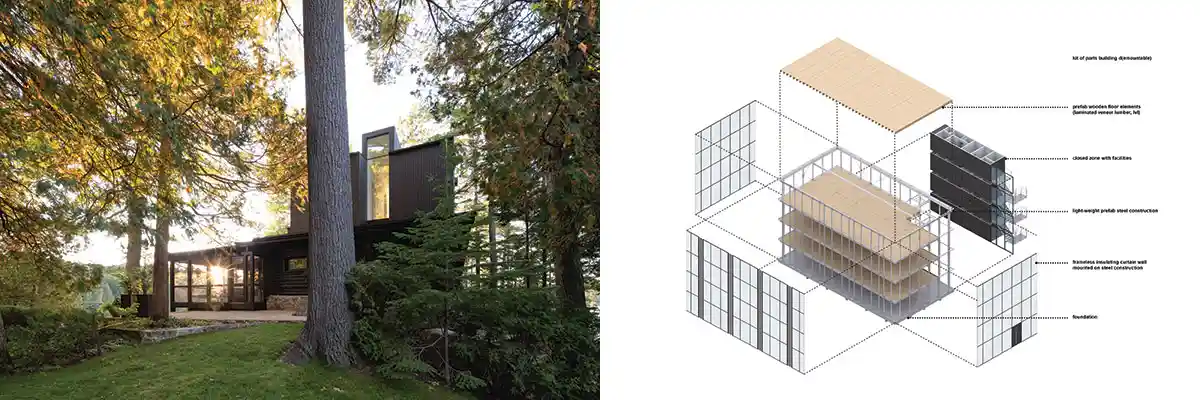

Building D(emountable) has exactly the same footprint as the existing building that was demolished. It measures 11 by 21.5 meters and has four floors of about 200 sqm of lettable floor area each. In addition to being demountable and remountable, the structure is also super lightweight: the use of materials is kept to an absolute minimum. The building is also completely flexible in its arrangement, has no gas connection, and is equipped with heat recovery. The ground floor is made of poured concrete, but otherwise, all building components are modular and dry mounted. Supreme simplicity has been an important principle in the design.

Steel, wood, and glass

Building D(emountable) consists of a rationally optimized building kit with a steel, prefabricated and extremely slender main supporting structure. The structural floors and roof are made of lightweight wooden Laminated Veneer Lumber (LVL) elements that are also prefabricated. These have a compact height and the installations are integrated within them. The ribs of the LVL elements remain fully visible and are part of the building’s aesthetics. The screed is biobased and consists of gravel-like granules in a cardboard honeycomb structure with gypsum fiberboards on top. The entire screed is dry and easily removable again.

The PVC finishing floor is made of partly recycled PVC. The building has no window frames: the double-layer insulating glass is mounted directly on the steel structure. For that reason, the steel construction is provided with welded screw profiles. The steel builder had to comply with the very limited tolerances of the façade builder, which was no small task. The facade is largely transparent, which makes for strong sightlines and relations between the inner and outer world. Vertical slat strips can be opened for natural ventilation. The down-to-earth, modern building strikingly and interestingly contrasts with the historic existing buildings. This also renders it illustrative for the way cepezed approaches the combination of new and historic construction.

Climate

The entire building functions as one large fire compartment. As a result, little material was required for fire-resistant measures; only the stairwell has a fire-resistant partition. All climate control works on air. On each floor, air conditioners that also take care of heating are integrated in the ceiling. In addition, the building is equipped with a heat exchanger. Roller blinds provide sun and light protection.

Integral process

Construction took place in an extremely short period: just over half a year. With the positioning of the elevator shaft, the building even topped out in an hour after the works started. The complete structure of steel skeleton and wooden floors was put together in three weeks. This was possible, among other things, because of an integrated process with thoughtful preparation and close, integrated cooperation between the various cepezed disciplines; from the project developers to the architecture and interior designers and of course the implementation coordinators.

With short communication lines, all specialists are housed under one roof, which has not only improved the efficiency of the process, but also the level of coordination and thus the quality. There was a close collaboration between the designers and the construction coordinator throughout, with key figures from the design also being part of the implementation team, as were the external partners for structural advice, building physics and fire safety, steel construction, floors, facades, MEP/HAVAC etc. In terms of time, use of materials and financially, the project resulted in a high degree of efficiency.

Source: v2com

Photo credit: lucas van der wee | cepezed