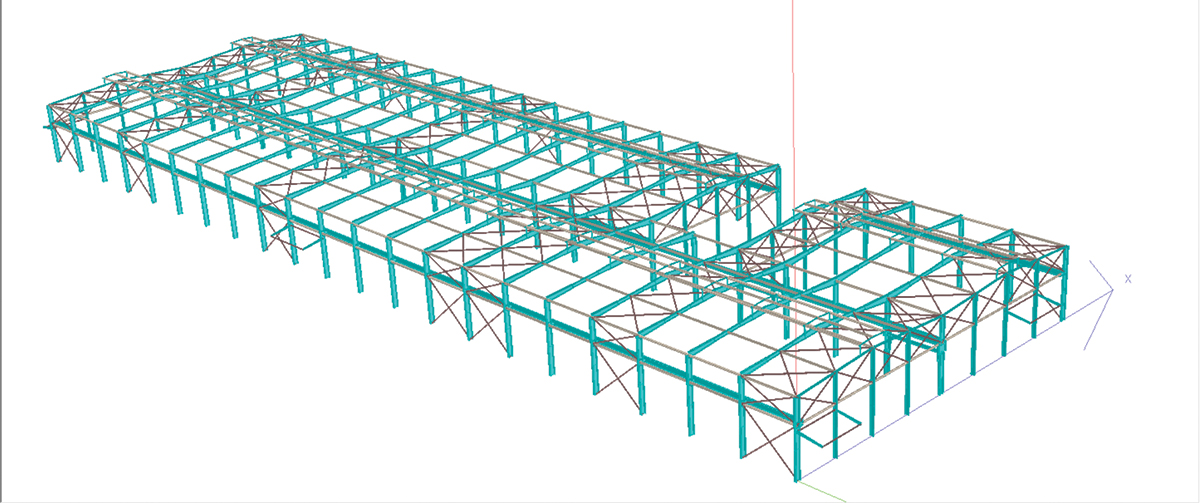

An industrial warehouse building is typically identified by its massive volume - its long span and height. It is easier to achieve this volume now (as compared to last decade) due to availability of modern materials like higher grades of steel. In one of our warehouse projects for Transport Corporation of India (TCI’s largest warehouse project) at Pataudi Road, Gurgaon, we customized the portals in such a way that two out of three consecutive portals did not have central columns. By using specially designed jack beams - an innovative solution - we got multiple 27mx75m column-free spans. These features eventually became the USP of the warehouse and helped TCI to lease it out to e-commerce giant Amazon.

These days, structural design optimization is possible due to technology advancements and modern engineering. Optimum design of steel structures accounts for the behavior of semi-rigid connections.

We achieve ample natural light by use of polycarbonate sheets in the roofing. And for natural ventilation, we use ridge monitor and turbo ventilators. It is also very important to maintain visual connection from the working space to the exterior areas, and we achieve this by placing large windows in the external walls.

Innovation by design is the outcome of a designer’s approach and sensibility in addressing the needs of the clients. With over 400 successfully completed Industrial & Warehousing projects pan India and 28 years of experience, we have seen a great evolution within our own design approach, born of a constant drive to improve our design processes and services, and to consistently innovate and adapt to the rapid technological changes

Ar. L A Murthy, ArA. Amit Murao

In most of our projects, we use fascia truss at the gable end of the structure – which has numerous advantages. It is structurally very stable and can eliminate the need for gable end portal with multiple intermediate columns – which would have been otherwise required to support purlins, which would further support the sheeting. Moreover, if we are planning for expansion, then we can have fascia truss with gable end portal and once we do the expansion, this fascia truss can be simply lifted with a crane and relocated to the new gable end. Moreover, this truss may be used for support of the cable tray and of various pipelines (fire, compressed air, etc).

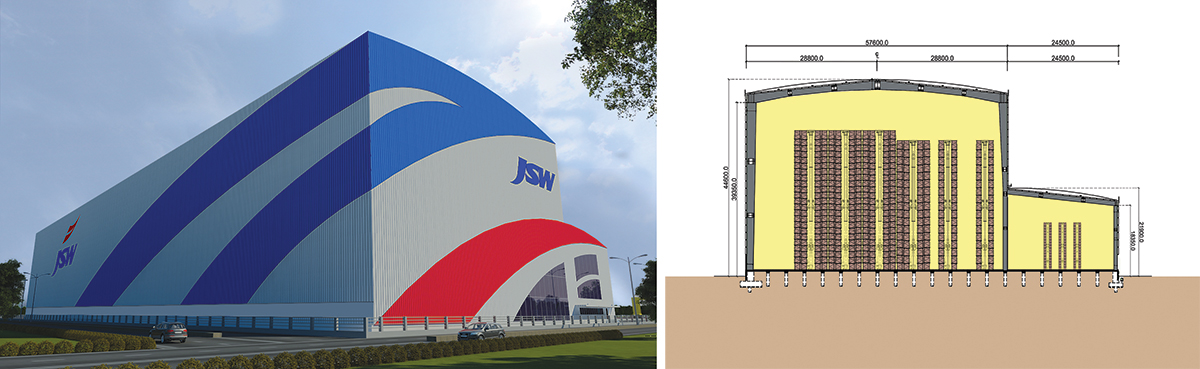

The automated storage and retrieval system (ASRS) has brought a great change in modern warehouse design. It consists of a variety of computer-controlled systems for automatically placing and retrieving loads from defined storage locations. This futuristic process has helped us tremendously in efficient use of space, and using this concept, we are now creating warehouses of up to almost 40m in height as the ASRS system can now easily access the higher-level palettes!

Our latest ongoing project – JSW Central Storage Warehouse in Dolvi, Maharashtra - is one of its kind; it uses the ASRS technology (designed by ThinkLink). The warehouse has a height of 39m, width of around 81m and a length of 196m with a 57m wide, flexible column-free space. Once completed, this will be Asia’s largest MRO warehouse.