Skylights, which are supposed to bring light to your life, often do spring a leak and by the time it is diagnosed or even detected, they would have damaged the ceiling or even form a puddle of water below. Typical causes of a leaking glass or polycarbonate roof are the inadequate flashings, loose capping or perished seals. Sealants can fix seals temporarily but it is never the answer. Another major cause of leakage, especially in the metal roofs is fastener movement. Thermal shocks cause fasteners to loosen and back out.

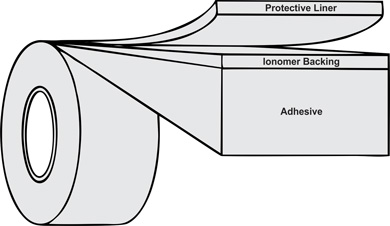

3M launches for roof sealing application, a unique and dependable product – 3M™ Extreme Sealing Tape, 4412 N- a single coated, pressure sensitive adhesive tape, designed for difficult sealing application. The backing on this tape is an ionomer film that is very tough yet flexible and yet abrasion resistant. The very soft and thick acrylic adhesive has excellent sealing properties and outstanding outdoor durability. This single coated tape is designed to seal over an existing joint, seam or penetration. The adhesive is designed to adhere well over the ionomer film to enable overlapping of the tape and yet provide a tight seam to itself and the joint or seam to be sealed.

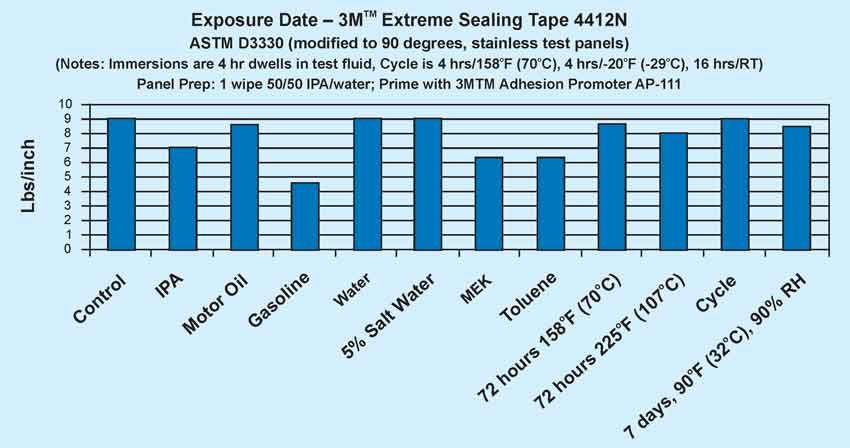

The long term high temperature tolerance (days and weeks) of this tape is 93°C (200°F) while the short term high temperature tolerance (minutes and hours) of this film is 149°C (300° F). The immersion resistance, temperature resistance, high humidity resistance and temperature cycling resistance of Extreme Sealing Tape is demonstrated as below :

Extreme Sealing Tape has been subjected to accelerated aging tests, conducted at 3M Weathering Resource Centre at St. Pauls, Minnesota. Over 2000 hours of accelerated aging exposure of the tape indicated on cracking or chalking of the 3M™ Extreme Sealing Tape 4412 N. The tape still had 10 pounds per inch width of peel adhesion strength.

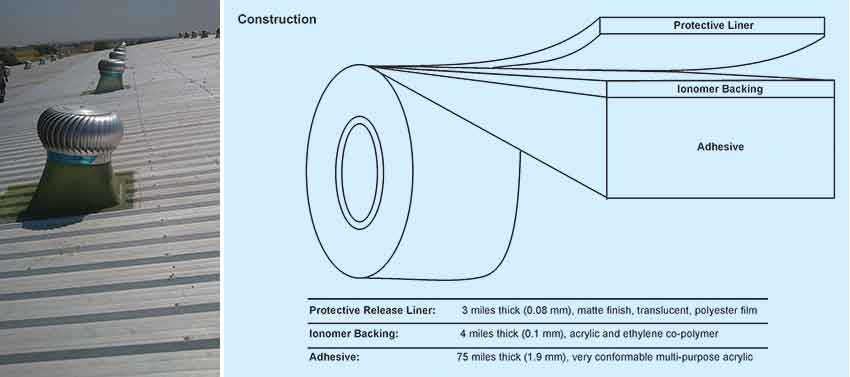

Pre Engineered Buildings (PEBs) are now the latest trend in India. In a bid to improve the indoor air quality turbo vents have become a norm providing natural and fresh air ventilation. Leakages at these spots are quite common and conventional sealing products are hardly a success. It is here, where the effectiveness of Extreme Sealing Tape is quantified with the cost benefit ratio considering the lifecycle of the product. Reputed PEB manufacturers in India have already used 3M Extreme Sealing Tape in large quantities for their projects spread across the length and breadth of the country and they keep doing so to keep their profits and reputation intact.

Typical application areas are not limited only to roofs, skylights and PEBS; it is also an excellent choice for the roofs of buses, trailers or vans. With time, the advantages become even more obvious. From rain gutters to flashing and vents, Extreme Sealing Tape is a sure winner over sealants. With no sticky mess on your hands, fast installation and proper aesthetic you can seal the extreme with 3M™ Extreme Sealing tape 4412 N.