India is on its drive for a massive infrastructure upgrade and the construction techniques in the country have seen a major elevation over the past few years with the adoption of global practices. Germany has several well-proven building techniques available which may be of good use in India as well. Especially, the techniques of pre-fabrication and reduction of on-site activities is well worth consideration and careful adoption.

Pre-fabrication is the practice of assembling components of a structure in a factory or other manufacturing site, and transporting complete assemblies or sub-assemblies to the construction site where the structure is to be located. This construction technique offers the most innovative and quicker methods of construction ensuring efficient, cost effective and speedy completion of projects which is perhaps the pre-requisite for the Indian construction sector (where infrastrucutre development is on full swing) to meet tight construction schedules and demanding deadlines.

Development in the German Market

The entire industrial and commercial world has been changing swiftly during recent decades. New information technologies together with highly optimized supply chains and distribution procedures and the tremendous growth of productivity have promoted the demand for industrial edifices in Germany.Nowadays the German building industry faces an increased requirement for

- Widespread single-storey logistical and production buildings. The typical ground floor area ranges from a few ten thousand up to hundred thousand square meters and should be as column-free as possible. The height is on average round about fifteen meters due to fire regulations and to avoid unnecessary air conditioning costs.

- High rack storage areas which house fully or semi-automated storage systems. Those buildings commonly tower up to 60m or more while showing ground floor areas of some thousand square meters. The enclosed racks are usually used as a supporting skeleton.

- Multistorey buildings for complicated production lines or sales floors, especially in commercial or industrial areas with space limitations. These buildings feature up to three or four slabs of high bearing capacity and are fully air conditioned. Fire regulations are also an important design criterion.

- Wide spread and intricate production shelters, which are designed in accordance to the requirements of the production processes, as there are power plants, steel mills, chemical plants, and so on. The edificial part is understood as being a machine shelter providing the proper conditions for the enclosed assets.

Conditions and Requirements

The conditions in the German industrial building scene are set by competition and fastidious builder-owners.The majority of newly built industrial and commercial buildings are large and hence enclose considerable property costs, large volumes of building materials and on-site labour. The tied-up capital is correspondingly high, thus investors seek to shorten the building time whenever possible.

Furthermore, there is always an extreme pressure to keep the building costs. General contractors face fierce competition and therefore are struggling in a buyers' market. It is common practice to agree on fixed-price contracts, which leave no leeway to either calculation or execution errors.

Industrial and commercial buildings are understood as being functional in the first line and hence not the object of prestigious architectural design. Nevertheless, a nice appearance is taken for granted and so is quality of material, craftsmanship, and design in all its facets. It is inevitable to meet the building standards, legal requirements, and the bill of quantities in every detail.

Building Strategies

Driven by high labour costs and a strong belief in the proven advantages of pre-fabrication, German contemporary industrial building culture is characterised by an extreme reduction of on-site activities.Whatever can be done in advance will be done in advance. Wherever there is an opportunity to reduce the number of parts it will be opted on.

- The usage of wide spanning materials is invariably the first choice because it decreases the number of structural members.

- Reduction of material and transportation costs is accomplished by the use of light-weight elements wherever possible.

- Logistic operations are reduced to the unavoidable minimum.

Building Techniques

Concrete members

Cast in place concrete is perceived as an old-fashioned practice and is to be reduced down to the inevitable minimum. Even foundations are often executed in pre-fabricated style and it is common practice to bring the columns in one piece, together with their individual footings.All beams and other concrete members are cast in advance in specialised workshops, transported by special vans, and maneuvered into their final position directly from the loading cradle. A sophisticated range of special joint equipment, cushion materials, and special grouts are available and will be at hand as foreseen by the routeing department. The application of high-tech measuring tools guarantees the proper installation of those extremely heavy concrete elements.

Slabs are either fully pre-fabricated – often pre-stressed slabs with hollow core sizes – or partly. Partly prefabricated slabs form self-supporting scaffolding, which allows an adaptive reinforcement and need to be completed with on-situ concrete.

Steel members

The usage of primary steel members does not particularly differ from what is common in India.Secondary members

Secondary members are commonly made out of thin cold-shaped steel sheets. Moulding is either achieved by edging — piece by piece — or by continuous milling. The cold mill process is advantageous in terms of structural optimisation and cost effectiveness. In practice it is the flexibility provided by numerous small and medium scale edging workshops, which leads to their market domination.Roofs — Cladding, Insulation, and Sealing

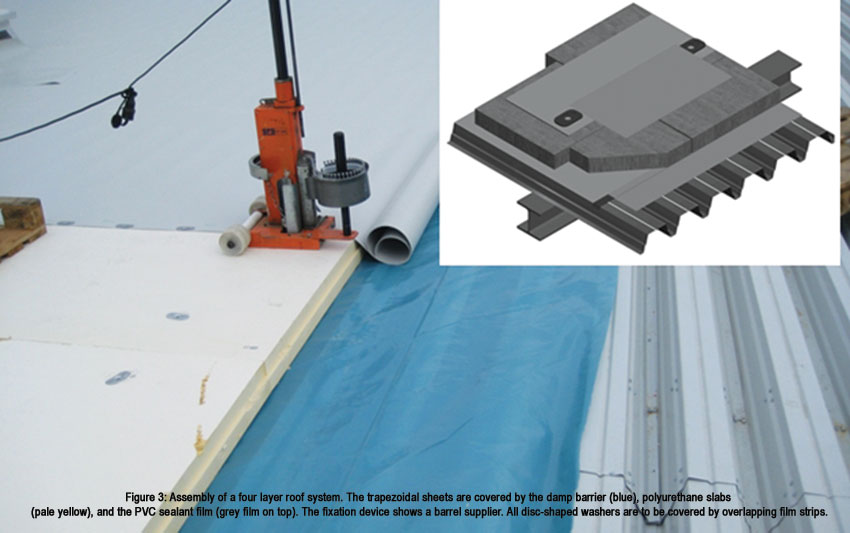

The prevalent roofing system is made out of four layers:- The deeply corrugated trapezoidal sheet, which spans from truss to truss, thus bridging widths up to nine meters.

- The inevitable damp barrier which protects against moisture intrusion.

- The insulation layer, formerly prevalent polystyrene, nowadays either mineral wool or polyurethane.

- The mechanically fixed sealing film. This is a waterproof skin very much comparable to the films one uses for the impermeability of swimming pools or artificial ponds.

There is no need for purlins. The sturdy trapezoidal sheets provide the scaffolding on which the subsequent lots can be applied. The films are welded to each other by hot air in a way that all fixation screws are covered by the overlaps.

Especially widespread building, i.e. ground floor area greater than ten thousand square meters, are nearly solely covered using this technique.

Walls — Complete Functionality in One Shot

Due to strict environmental specifications and the benefits of prefabrication sandwich panels are builders' first choice once it comes to the cladding of such buildings.Sandwich panels are continuously produced three layer compound elements. Two thin steel sheets are glued to a hard polyurethane hard foam or - because of fire protection regulations - at times to mineral wool. This compound provides a reasonable structural rigidity whilst avoiding any metallic thermal bridge except a few screws.

A fully-fledged wall can be assembled in one work step. A four member crew equipped with a trailer mounted crane and one or two lifting platforms is able to install up to 400 square meters per day. Thus even the cladding of very large wall areas becomes a question of weeks but months.

Conclusions

As India is being challenged by the urgent need of rapid improvement of its infrastructure including air conditioned cool or even cold logistical and storage buildings, production halls, power plants, hangars, and many more, there is a dire need of faster and cost effective method of construction which can increase productivity and efficiency without ignoring. And here stand the role of prefabrication building system which is faster, highly durable, weather & corrosion resistant and most important cost effective method of construction. It's already making waves in various construction sectors in India as industrial warehouses, factories, educational sector etc and hoped that it will have sprawling market in all other sectors including commercial to mass housing.

Dirk H. Urbanek is German graduate engineer and an expert and consultant in light-weight constructions. Focus of his professional activities is on industrial building techniques as sandwich panels, trapezoidal sheets, and roofing and cladding of widespread buildings in general.

Mr. Urbanek is CEO of ZBN Civil Engineers Ltd in Germany and ZBN Lakshmi Civil Engineers Pvt. Ltd in Rajajinagar, Bangalore. Both offices are concerned with advisory service, structural and work shop design of major industrial buildings.