The pre-engineered building technology, which entered the Indian construction arena during the late nineties has over a period of time gained widespread acceptance among the end users and is steadily making inroads in the construction and infrastructure projects across the country. This is largely due to the fact that PEB-based construction technique is offering the most innovative, hi-tech, and quicker methods of construction ensuring efficient, cost effectiveness and speedy completion of projects, which is perhaps the pre-requisite for the construction sector to meet tight construction schedules and demanding deadlines.

Drawing overwhelming response from construction and infrastructure builders, due to heightened construction activities currently going on across the country, the global players in the PEB industry have not just set up their shops but also launched multi-prong brand building initiatives by holding technical seminars, exhibitions and events displaying their products to popularize the benefits of PEB brands. In the process, they have been able to create awareness informing people that under the PEB systems buildings are built keeping the, eco-friendly environs, aesthetic value, designing, durability, energy efficiency, cost effectiveness and speedy completion of the construction projects in mind.

With increased emphasis on the on-going green buildings ensuring sustainable construction, the PEB structures are created with a high proportion of recycled content making them lighter by about 30% than the conventional steel buildings. They contain higher degree of fire and dust resistant and are maintenance free. As a result today the PEB system is the most preferred choice among the architects, builders, developers and industrialists. The experts in the field are unanimous in their view that the PEB industry in India is currently heading to achieve growth trajectory of about 35% per annum.

To know more about the PEB systems, its evolutions, benefits, future prospects and an unassailable edge it enjoys over the conventional systems of construction, MGS Architecture has interacted with cross sections of experts engaged in the field and has also elicited views of the captains of the PEB industry for the benefits of its readers.

Kirby Building Systems India Ltd.

Sharing his viewpoint with the MGS Architecture, Mr. D Raju - CEO, Kirby Building Systems, explained that while selecting the right type of building material for the project in hand, the pre-engineered steel building system is a preferred choice because of its cost effectiveness and its potential to provide a quicker solution to those setting up industrial and commercial facilities. The economy comes from the fact that pre-engineered steel building mechanism comprising primary, secondary and cladding components are designed as a system. The use of high strength steel & possibility of manufacturing sections with varying/tapered section sizes to match bending moment diagrams allows economizing the use of steel to achieve optimum weights.

Elaborating on the Kirby's presence in the country, he revealed, the company is a part of the Alghanim Group of Industries, Kuwait based multinational business conglomerate with diversified businesses. Kirby Building Systems is one of the world's largest producers of quality steel buildings and has been operational since 1976. The company recognized the need of customers and the potential in the Indian market and was the first to set up a mega manufacturing facility in India near Hyderabad in 1999. Since then the company has aggressively promoted the use of PEB concept in India.

The opening up of the Indian economy in the early nineties resulted in an influx of multinational companies into India and the use of this concept spread widely in the country with Kirby being the torch bearer. Today, at 200,000 MT capacity per annum and presence across different industry segments through steel buildings, Kirby is the market leader with more than 8 million sqm of Pre-engineered Steel Buildings in India and its ability to handle any size of project remains unmatched. Kirby's product portfolio includes PEB, Sandwich Panels, Industrial Racks, etc. Sharing Kirby's dominance in the Indian market, Mr. Raju said that Kirby enjoys a market share of over 40% and maintained its dominance in the PEB market. Kirby India has executed over 10,000 buildings till now from a simple Warehouse building to the most complex Shipyard building and has a customer base of over 3,500.

Kirby has the privilege of partnering most of the leading corporates across different industry verticals by setting up their facilities. To name a few, Kirby has been associated with companies such as Nokia, Skoda, Tata, Reliance, UNICEF, Swaraj Mazda, BMW, Renault-Nissan, Suzlon Group, Birla Tyres, Apollo Tyres, MRF Tyres, Bridgestone, Pipavav Shipyard, Jindal Group, Mahindra Group, JSW-Toshiba, etc.

Mr Raju said that the company's Standing Seam Roofing System (KSS-600) is tested and approved by FM Global, USA and has double lock standing seam ends which provides 100% leak proof buildings with faster installation. In addition to these, implementation of SAP in 2008 further strengthened Kirby's internal processes and operations which are well integrated thereby ensuring better customer service.

He said adding that our company has always invested in the awareness programs and brand building exercise through participation in exhibitions, seminars and conferences and through advertisements. Today, Kirby has become a generic name in the Pre-engineered Steel Building market in India and has maintained its market leadership because of its state-of-the-art manufacturing and engineering facilities, strong execution team and a network of over 100 certified builders. Kirby India has 25 sales offices across the country equipped with experienced resources and is always planning to expand its geographical reach to smaller industrial towns to be near to its customers and maintain its leading position in the Indian PEB market.

Pebs Pennar

Elaborating on the advantages of the PEB over the conventional system, he said that the Pre-engineered Buildings are economical, faster to construct, aesthetically appealing, durable, re-locatable, earthquake resistant, easy maintenance, factory controlled quality with wider spans network. In this connection, we are conducting seminars at various important cities and inviting consultants, architects and customers. We are explaining the benefits of PEBs in these events. Also we are participating in exhibitions and trade events like Roof India, Metal Buildings Systems etc. In most of the projects, the customers are guided by the consultants and architects for the complete turnkey solution. To face the tough competition in the PEB market we have a qualified talented and experienced team in our engineering, sales, production and erection department. The team has been chosen to outperform in all quarters with their unmatched expertise of world repute, capability to understand complex structures and in-depth knowledge of designing pre-engineered buildings.

Our state-of-the-art manufacturing facility at Hyderabad has been equipped with high precision CNC machines to fabricate and supply quality-replete steel buildings. We offer Double lock standing seam roof sheeting in technical collaboration with NCI, USA, which is 100% leak-proof and a proven product in USA for the past 50 years. We have a dedicated project management department which takes care of erection and after sales service. To cater to the aspirations of the customers we are providing multi-storied buildings for both commercial and residential segments and currently using Autocad, Stadpro, MBS & Visomax software's for designing our Pre-engineered buildings projects.

PhenixVP

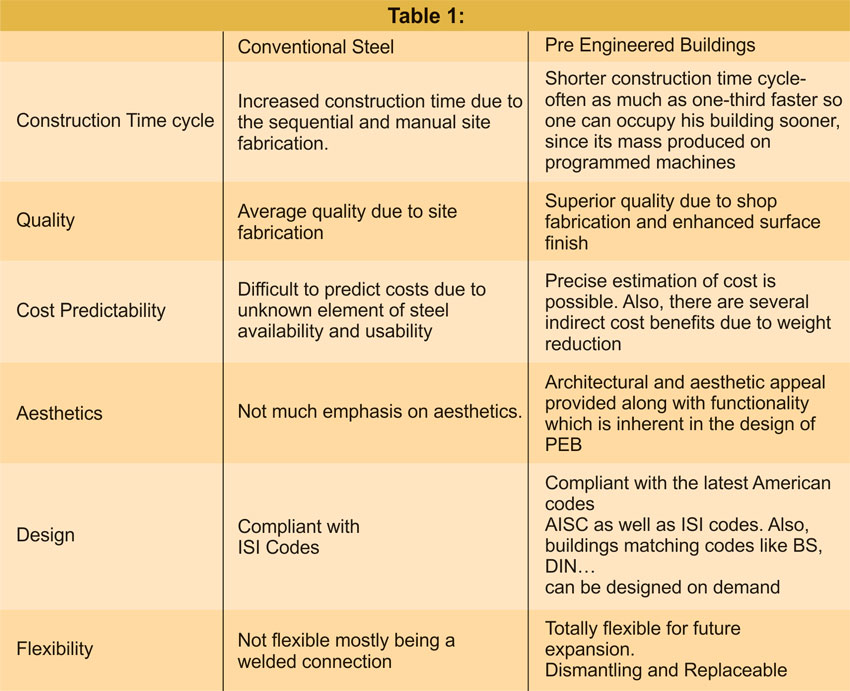

Elaborating on the advantages of the PEB system over conventional methods of building, he gave the detailed analytical explanation in the Table 1.

Explaining the awareness level among the industrial building customers, he said that the builders have accepted that optimized technology and flexibility which is being offered by PEB is unmatched as compared to conventional buildings. They have now started realizing that the Pre-engineered buildings have much more to offer than just the industrial building complex. In totality, the quality of steel used in PEB is superior as per the standards laid down by the MBMA. This helps out to optimize the design considering the dynamic loads, seismic loads, and wind speed to provide a better product at a lower price as compared to conventional buildings and they can be designed as per any IS standards. In this connection, we undertake programs to increase awareness about PEB by organizing technical seminars, exhibitions and advertisements. Also, our marketing team tries to educate the new clients and consultants and helps them reduce the cost. Currently, we are providing multi–storey buildings up to G+5 floors both for residential and commercial purposes.

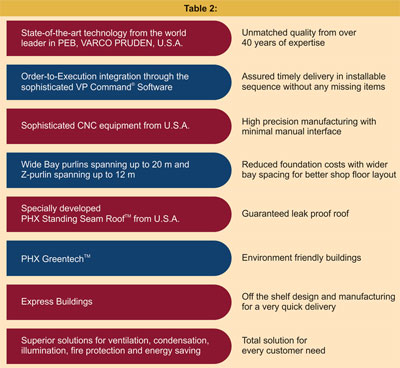

In order to maintain edge in the face of tough competition, we offer tech- nical advantages in design, fabrication, installation and top class after sales service to our customers by adhering to the guidelines given in Table 2.

Zeppelin Mobile Systems India Ltd

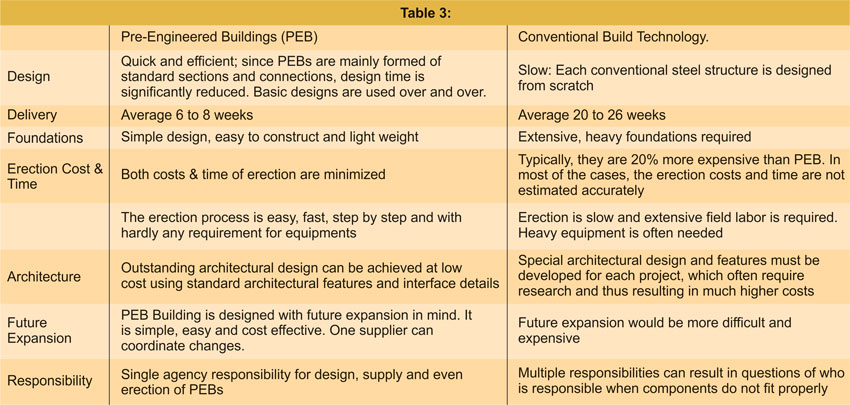

The Deputy General Manager, Sales, Zeppelin, Mr. Shiv Kumar Gupta, in his conversations with MGS Architecture, reiterated that PEBs have tremendous scope and brighter future prospects as a solution to industrial and factory buildings in India. We at Zeppelin intend to be recognized as a leader in the PEB. This would be accomplished through pledge ensuring product perfection, engineering excellence and the best customer services in the industry. The applications of PEBs will be driven by multiple factors including spreading awareness of advantages of PEB over conventional buildings, synchronizing with the customer aspirations, requirements and suitability to build optimum capacity, efficient & cost effective steel factories made of PUF panels for quicker return-on-investment apart from designing and fabricating safe and technologically advanced PEB buildings. Likewise its usages will also be augmented by offering customers versatility in design & fabrication to meet their exact building & facility requirements, besides offering better after sales services to the utter satisfaction of our customers. He explained the pluses of PEBs over the conventional methods of building in the Table 3.

Lamenting that the customer base today doesn't have sufficient awareness about PEB's as the optimum building technology for their applications, in this connection our company is focused on building this market and will make all out efforts to increase the awareness leading to the adoption of PEBs on a larger scale.

Our company is currently using STAADPRO software based on design and analysis of PEB, as this software has been approved by various government departments and also by MBMA. This can easily calculate the live load, dead load, seismic load and wind load. As of now our company is providing Mezzanine up to three to four meters besides providing the PEBs up to 28 to 35 meters height.