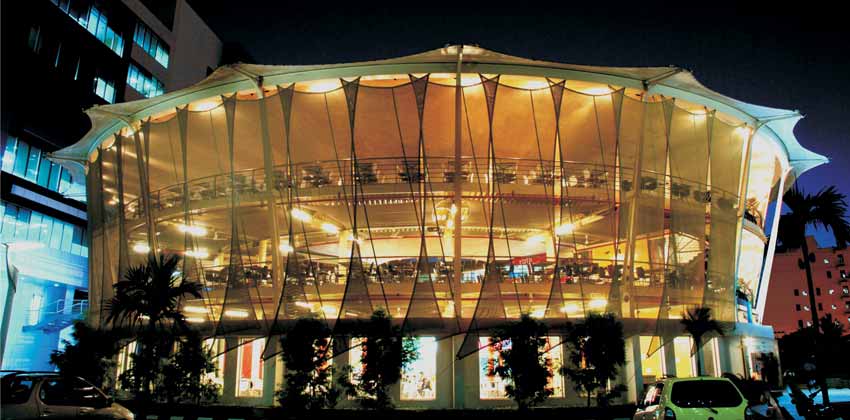

What better way to refresh tired minds and bodies than to energise them with fresh air and light? This idea is the underlying concept of the design solution offered in response to the brief for the creation of a recreational food court building for the employees of IBM at Bangalore.

The Brief

The objective of the brief was to create a building of about 40,000 sqft. to house various multi-cuisine restaurants with requisite seating, cooking areas and auxiliary services. The structure was to be a lightweight and aesthetically designed one, which could be constructed at a fast pace. Energy efficiency and eco-sensitivity were to be considered bearing in mind the responsibility to address these issues.The Solution

Along the lines of the architectural and engineering requirements that the brief put forward many alternatives were presented. The solution that finally crystallized was in the form of a building with pre-fabricated components in structural steel along with lightweight new-age materials. A circular footprint with polar symmetry was conceived for its superior advantages in terms of industrial standardization. In aesthetic terms this translated as a soft streamlined form speaking a contemporary language – a structure that boldly displays the technology and materials it is created out of.Structure and Materials

Structural steel and lightweight roofing and façade materials have been put together with innovative joinery to create this technically sound building. The supports, connections and materials are honestly displayed and impart a beautiful modern aesthetic language to the structure.The prefabricated steel components have been designed and fabricated such that 80% of the total work involved in the construction was carried out at the workshop prior to the commencement of work on site. This meant savings in terms of on-site working time, control on accuracy and finish and optimisation of material and labor. All this directly links to cost efficiency.

The structure consists of 18 peripheral steel columns that support a peripheral ring beam. An internal ring beam that defines the central cut out is supported by 18 pre-stressed cables, which connect to the lowest level. There is no cross-supporting for the roof. Panels of pre-stressed P.V.C. membrane that have been seamed together stretch continuously between the two ring beams with an inward slope forming the roof cover. The roof is strong enough for a person to walk on it for maintenance purposes. The façade does not have typical walls and windows. Instead, P.V.C. mesh membrane panels are stretched like the sails of a ship using cables from the top level to the lower level. This mesh blocks the vision from the outside, but lets the people inside have a view of the outside. Over 70% of the periphery is in mesh and the balance is in glass and steel sheets. These materials are used for enclosing areas that needed privacy or insulation.

The main structure itself supports the floor and roof avoiding the need for a secondary or tertiary structure. The intermediate levels have castellated steel sections with steel chequered plate flooring. The design of the floor optimises the use of material and renders the flooring light, yet strong. The voids in the steel supports are used to pass service lines through.

Environmental impact

The environmental impact of the structure has been continuously considered and the technology, materials, and planning reflect this.The life span of the steel structure is about 50 years and that of the P.V.C. fabrics is about 30 years. All materials used are completely re-cyclable and the building itself can be dismantled and erected elsewhere. The circular design utilizes hoop stress effectively and minimizes sizes of supporting structural members thus saving on material. The detailed joinery involves minimal on site welding and saves time energy and labor. The super-efficient light materials used ensure that the dead weight of the structure is 20% of that of a regular structure.

The interiors require no daytime artificial lighting due to the translucent roof and mesh membrane facade. At night also the bounced off light minimizes lighting requirement. The need for artificial ventilation is also low due to the permeable mesh and central opening in the roof.