Tensile has its roots in Ancient History

The history of tensile structures and tent-type housing, is as old as mankind itself. Leaves, barks leather and felt, existed much before fabrics.The Ancient Egyptians were probably the first civilization to use pieces of fabric for shade. They also found sails useful for harnessing the power of the wind to travel in sailing boats from 3,500 BC.

Equipped with a Master's in Membrane Structure, from Germany, Bhavini Mistry Jotani, M Archineer, engineers all design projects under the uniquely named Ahmedabad based Freitagmann, which specializes in designing, engineering and execution of light-weight structures and Innovative structures. Her views on the history of tensile forms is equally unique, "When I think of tensile, the Bedouin tents and the old Indian/arab markets with fabric roofs comes into my mind. But that is very personal and contextual," and adds "In today's times when one says tensile architecture, there is a whole new architectural language that springs up. Right from the big stadia and airport roof canopies to large span public spaces and mall-atriums."

Today, tensile architecture represents, ease of use, light, elegant, versatile and sturdy fabric, that builders and architects endorse.

What comes to your mind, instantly, when you hear or read the word 'Tensile Architecture'? We asked some professionals using tensile fabrics with excellent, long-term results.

Richard Mcdonald, President, Taiyo Membrane, India Operations- "Simplicity in geometric form but complex in design"!

Shehzad Irani, M Archineer, SCHAFBOCK- "Free flowing forms, fabric, lightweight structures, open spaces, warm natural light."

Simran Dodeja, Senior Marketing Manager, McCoy Architectural Systems- "Light weight structures, versatile, dynamic, free flowing forms, architecture in motion."

Tensile membrane applications

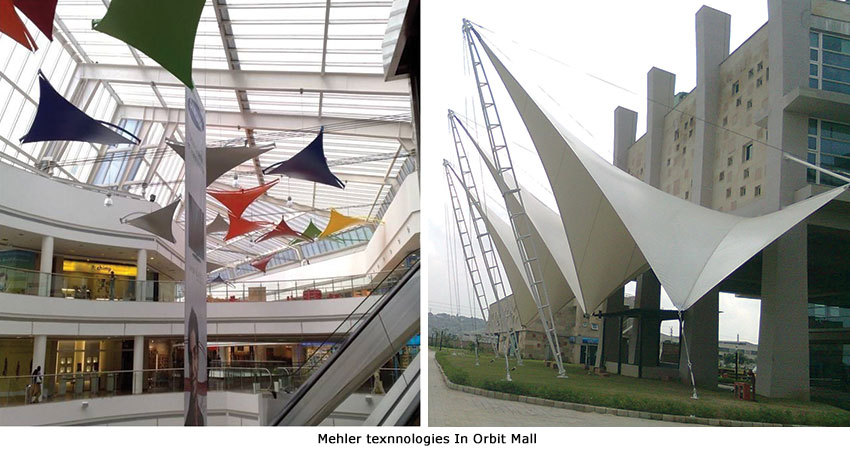

While all agree that atrium structures, large canopies at airports, amphitheatres, stadia, car parks, bus drop-offs, garden structures, cafeteria, food courts and gazebos, mall coverings, would benefit tremendously from the high translucency and properties of the membrane structure. Faraz Aqil, Director, Mehler Texnologies, adds a note of caution, "For best and long-term results, fabric selection plays an important role and the end users must be briefed on maintenance and cleaning of these structures."

The advantages to the builder, to the architect, and to the end users, of tensile architecture, in place of the erstwhile used methods and fabrics

Reveals Shehzad Irani, "Using a tensile membrane roofing structure, reduces the overall loads on an existing structure, if designed properly. It gives a very good light quality, thereby reducing the overall illumination expenses of a space; the membrane roof itself is very flexible and hence is able to deflect considerably and hence resists earthquake loads. It also has a very small cross-sectional area, and hence cools down very quickly. Therefore in temperate climates, it doesn't trap the heat in its mass. It is quite eco-friendly since the fabric is easily recyclable and the rest of the structure is steel, which can also be re-used. The manufacture of any of the components does not entail any toxic methodologies. They are very quick to install and demolish, since they are mostly pre-fabricated structures. They have a very low mass and hence can be even designed to retract/collapse easily".

Fabric being flexible, allows the architect to create striking forms and signature structures, extremely difficult with other rigid materials. If required, fabric structures can be designed to be modular and dismantlable. Being light, and flexible, they can also be easily stored and transported. A wide range of colors are available in certain types of fabric with customized options."

Bhavini Mistry Jodani gives a comparative analysis, "The best advantage to the builders, is the coverage area, versus the cost per square meter area, when one compares tensile structures with regular concrete structures, or even run of the mill roofing solutions. The aesthetics of the tensile membrane structure, is always an architect's delight, the light quality and the form of tensile, is like poetry.

Tensiles completely change the space quality. The volume of space that one gets in doing a tensile roof helps in decreasing the room temperature, especially in a tropical climate like ours. On the technical side, the cross section of tensile fabric is less and also fabric color is mostly white. A great percentage of sunlight is reflected back, while the thickness of membrane is so less compared to the concrete structure that it cools down equally faster. The amount of radiation from the membrane is lesser than a concrete structure."

Simran Dodeja gives it a new dimension, "Tensile membrane structures offer versatility of form, giving the designer the ability to think on 'out of the box' solutions, virtually impossible with other materials. The pre-fabricated nature of these structures reduces construction time, allowing other on-site jobs to be completed simultaneously. Membrane Structures offer both roof and cladding, in one structural element."

Faraz Aqil says that, besides being light, tensile fabrics are easy to install and maintain. They can be used to cover large areas with clear spans, they can take any form, shape or size; natural light helps in providing better surroundings and better ambiance.

Richard Mac Donald, wraps it up real crisp, "Pleasing to the eye, aesthetics, spanning large distances with minimal steelwork."

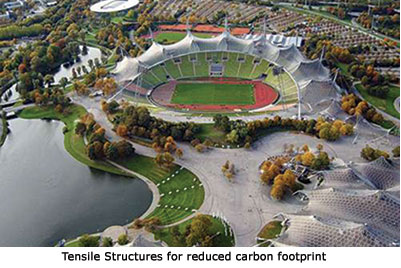

Construction materials used towards 'Green building objectives' and Reduced 'Carbon footprint'

The strongest boost for the construction and building materials industry, is the bar rising initiated by the national planning departments that focus on 'green' building. The green building materials market is growing exponentially, with the residential market being a major driver. In addition to the residential market, efforts are been taken to use construction products that are manufactured, from renewable resources. Added to this, is the use of tensile fabrics, that have distinctive advantages, in promoting the 'Green Building' concept, in India's construction arena.

"Tensile membrane Architecture is eco-friendly and is 100% recyclable. Even structures that support the membrane use steel, that is 100% recyclable, making this form of architecture perfect to achieve Green Building Solutions. Membrane structures allow diffused light and also help reduce heat load and can be extensively used as an alternative, to glass skylights, making these structures truly energy efficient" adds, Simran of McCoy.

Faraz Aqil boasts of Mehler's eco-friendly fabrics, "We are committed to using greener technology and almost all our products are 100% recyclable. Mehler eco-care & Vinyl 2010 contribute to preserve the environment."

Today's software tools for today's tensile architecture

"Nowadays a lot of non-linear, FDM based software have come into market like Forten4000, EASY, NDN. New software technology is being developed,, based on dynamic relaxation method, called Rhino membrane," shares Bhavini Mistry Jotani.

Shehzad Irani, elaborates on the software packages that drive tensile architecture, "You require a FEA (finite element analysis) package that can do linear and non-linear structural analysis, a Force Density method based form-finder, to find the form for the structure, a patterning software, that can handle complex flattening of geodesic curvatures. ixForten 4000, is a very comprehensive and cost-effective tool. In addition, you need a Nurbs-modeling software that can handle 3Ds and easily prepare fabrication drawings. Vector- works, Rhino 4, Autocad, Revit, are all versatile software aids.

Challenges in using tensile fabrics

In India, it is more the mental block of builders, consumers, architects and designers, who are not exposed to the changing trends, and remain soaked in age-old materials that are cheap and culture - friendly, that instill apprehe- nsions in their minds, to accept and adopt new membranes like tensile; resulting in the limited use of tensile fabrics in construction, besides the cost of these light fabrics.

Laments Bhavini, "The biggest challenge faced right now, is the base price of the material, since the fabric is not manufactured in India. We end up paying 30-40% more price compared to the European market, where most of the fabrics are also manufactured. Chinese fabrics are available in the market, but the quality is not reliable. More awareness needs to be created for the use of right technology and the benefits of tensile structures. One of the biggest challenge, in India, is to remove the blocks from people's minds, that fabric does not mean temporary. Because of the flexibility of the material and the age old use of fabric (eg. Shamianas, temporary extension of shops during monsoons and summer) in our country, people have this notion, that the life of the structure is not long. On the contrary, with the strength the material possesses and the quality of the fabric that is available, the life of the structure can be from 15 to 35 years which more or less can be considered a permanent structure."

Stressing on the need of the hour, Simran of McCoy says, "The biggest challenge that Tensile Fabric faces in India, is to create awareness about membrane architecture, which still remains to be explored by many designers and builders in the Country."

Shehzad feels the lack of compe- tency in handling geometric precisions, in tensile architecture, "Fabric structure costs much more because of the rich specifications that have to be offered with it. They are extremely complex to design and engineer, since the behavior of the structure, geometry as well as the material is non-linear. Their installation, production requires, trained and skilled personnel, which is scarce in India."

Faraz Aqil too lays emphasis on quality, "This is a cost effective solution, and not rocket science, but it is important to execute projects efficiently and fabricators should not compromise on the basic technical aspects of execution, in order to save costs."

Richard Mac Donald is completely aware of the situation and challenges, and hence, is brutally honest in his views, as to how the myths of the practising architects, can ruin the image of the membrane industry, "Getting architects and developers to accept the cost of using membrane. They believe a thin material is not necessarily durable and long lasting. Roofing companies, new to the industry, not understanding the complexities of tensile membrane structures and believing, it is easy to design and build and subsequently they produce a membrane structure, that is poorly designed, detailed and built; thus giving the membrane industry a bad name."

Tensile Membranes in India–Market Overview and Lead Players

Developing a Technical Guideline to Permanent Tensile ArchitectureThe tensile structure business has grown considerably in the last 10 years, and is predicted to grow exponentially, in the coming years. Such structures are becoming bigger and more sophisticated, as contractors, engineers and architects develop more confidence in their designs and reinforce them with their execution. Although the field may have evolved and more clients are interested in using them, they are still considered to be special – a new technology. Tensile surface structures do not figure widely in the design vocabulary of architects, engineers, urban planners, building owners and national authorities, and till that happens, their application will continue to be restricted.

Market projections, for tensile fabrics, pre- and post-economic slowdown, may be difficult to express in figures, without an accurate and deep study, but conservative turnovers would be close to 50-75 crores, per year.

How do big names fare, in the wake of poor acceptance, by the industry, of this new age, light material?

Says Ravi Mehta of Sujan Impex, which represents FERRARI, in India, "Initially we faced a lot of skepticism from architects, who were not aware of this new concept. However, slowly, as the architects in India got more exposed to international trends, and with a lot of foreign architectural firms also taking up projects in India, the concept of textile architecture has gained wide acceptance. People are realizing that, tensile architecture can be permanent, with life spans over 25 years."

Bhavini Mistry Jotani is optimistic about the market status, but is equally apprehensive of the cost and other issues. "India is an upcoming market for tensile structure. While European market is more or less saturated, and most of the international players are exploring the new asian markets, especially India and South East Asia. The tensile market in India, is around 15-20 years old. However, it is only for the last five years that it has been accepted in the Indian market. Many new players are coming into the market these days, but like any new technology or product in the market, some do justice to it by giving good solutions and by producing quality–tensile structure, while there are contractors who have half-baked knowledge and are invading the market, resulting in a disastrous end product, disappointing the end-user; creating a negative impact on the technology. I would say out of all the contractors and design-engineers in the field of tensile in India, only around 10-15% are qualified or have sufficient design-engineering knowledge of the technology and its application. Pre-recession saw fewer players, but the demand too was less. Post-recession has witnessed steep rise in the competition levels, almost 10 times, forcing everyone to quote competitive rates, and paradoxically, the base costs of fabric, steel and that of fabrication, have increased."

Lead players of the Indian Tensile market

Taiyo Membranes, FERRARI, and Mehler Texnologies lead the TA march, towards the new-age architectural world in India. McCoy is the perfect partner in project execution.Product features and applications

Faraz Aqil shares product features of his company, "Our Valmex FR Range, is one of the best PVC Coated Tensile memb- ranes available across the world."Salient features of Valmex FR includes: Both sides PVDF lacquered, 100% UV retardant, light weight and high strength, very easy cleaning and maintenance, resistance to microbial and fungal attack, translucent, thus enhancing power savings, flame retardant, 100% recyclable, a good example of environmentally safe and sustainable architecture, 10-15 years warranty and available in various width and sizes.

Ravi Mehta of Sujan Impex, says "FERRARI has a wide range of textiles for various exterior and interior applications such as, Permanent Roofing applications, Stretched Ceilings & Partitions, Solar Protection, Lightweight structures like tents, awnings & canopies."

"FERRARI fabrics are made to suit all kinds of climatic conditions and are used in the coldest areas of Russia and North Europe, to the hottest desert areas of the Middle East. Tropical countries like Singapore and Malaysia use these fabrics widely" he adds.

Richard Mac Donald talks briefly his company's excellence and product applications, "Taiyo is the oldest tensile membrane company in the world. It has over 50 years of experience in PTFE, PVC, ETFE, MDPE mesh and our company's strength lies in design, detailing and ensuring high quality finishes. Our light-weight membranes are extremely durable for the harsh Indian environment. The most prominent membrane we sell is PTFE or Teflon coated fiberglass, which is extremely durable with a design life of over 50 years. PVC/PVDF is with a design life of 25 years, for the highest quality PVC fabric available in the market."

Simran shares information on the market status of McCoy, "McCoy Architectural Systems Pvt. Ltd. is known for its ability to design and execute the most Complex of Tensile Membrane Structures in India, with some very prestigious projects under its belt, like the D.Y. Patil Stadium Navi Mumbai, RK Khanna Tennis Stadium CWG 2010, DDA Games Village Swimming Pool Structures CWG 2010, and many more. The Company is constantly innovating in the field of Tensile Architecture and spreading awareness of Membrane Architecture through various methods."

Shehzad confesses "Well very frankly, every fabricator would consider himself the leader, but some of the indigenous companies are–Western Outdoors, Shadeflex, Taiyo (not Indian), Construction Catalysers, McCoy Archite- ctural Systems, Skyshade technologies, Grorich, Polyklad, and Geodesic techniques."

Bhavini Mistry Jotani feels "Tensile is the most apt material for our kind of climatic conditions. It's just a matter of some time, before Tensiles would become an integral part of the Indian construction Industry."

The future of Tensile Architecture, in India, may be uncertain, but one thing that remains undisputed is that, "Tensile is light, bright, tactile and versatile."