Narayan Saboo, Chairman, Bigbloc Construction Limited

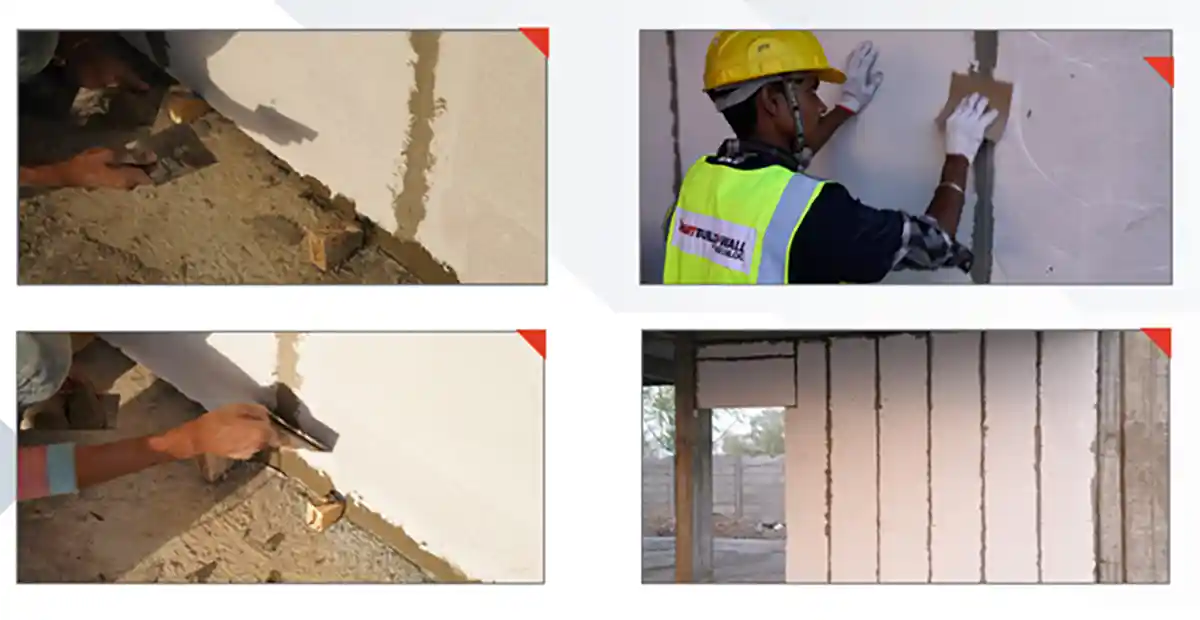

This need for speed and predictability is not limited to housing and offices. India’s data centre construction market brought in about USD 6 billion in revenue in 2024 and is forecast to reach USD 12 billion by 2030, driven by rising demand for cloud, digital and AI infrastructure. These projects require fast execution, high fire safety standards and consistent construction quality. To keep up with this growing need for speed and efficiency, the construction ecosystem is changing. Developers are slowly moving away from labour-heavy construction methods and adopting modern solutions such as precast components and lightweight blocks. Prefabricated systems, especially wall panels, make execution easier and timelines more predictable. These panels are manufactured in factories and assembled on site. They offer a practical alternative to traditional brickwork and on-site plastering, while helping ensure consistent quality and faster project completion.

Beyond quicker assembly, wall panels offer strong execution advantages for large and complex projects. This is especially relevant for data centres, manufacturing units and logistics facilities, where construction timelines are tightly linked to project viability. Since wall panels are manufactured off site while foundation and services work continues in parallel, overall construction moves much faster. Industry estimates suggest projects using wall panels can be completed 30 to 50 percent quicker than traditional brick-and-mortar construction. Factory-controlled production ensures consistent quality and helps reduce material waste by nearly 20 to 30 percent. Labour requirements are also lower, allowing smaller teams to complete installation efficiently. These benefits make wall panels well suited for industrial and data centre projects as well as housing projects that demand speed, precision and standardisation, particularly in markets where skilled labour availability and tight delivery schedules remain ongoing challenges.

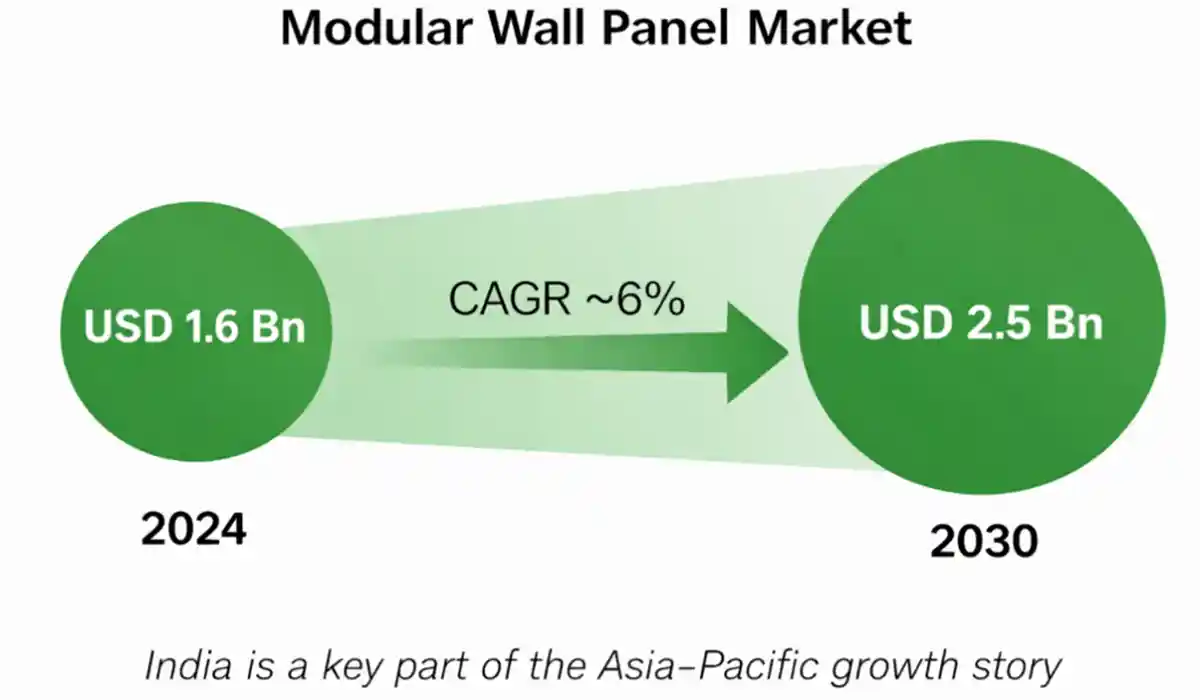

These execution benefits are translating into clear commercial advantages for developers and investors. The global modular wall panel market is projected to grow from USD 1.6 billion in 2024 to USD 2.5 billion by 2030, driven by rising adoption across commercial real estate, data centres, warehouses and industrial developments. In India, rapid growth in cloud services, digital infrastructure and large-scale manufacturing is increasing demand for buildings that can be delivered quickly and expanded easily. Faster construction timelines, predictable outcomes and lower on-site risk directly improve returns and reduce delays. As part of the fast-growing Asia-Pacific region, Indian developers are increasingly aligning with modular construction practices to stay competitive, making wall panels a strategic choice across both commercial and industrial segments.

As the construction materials industry evolves, developers are looking for solutions that are faster to build and more sustainable. This shift has encouraged manufacturers to move beyond single products and offer complete walling solutions. Today, the market includes AAC blocks, jointing mortars and large-format AAC wall panels that replace traditional brickwork and on-site plastering. These systems are increasingly being used across housing, commercial developments, industrial facilities and data centres where speed, consistency and predictable execution are critical and where reliable supply at scale is equally important. Companies are responding by investing in modern plants and expanding capacity, highlighting the growing institutional interest in this segment.

This shift toward modern walling systems is also being reinforced by government policy. Authorities are encouraging the use of prefabricated and advanced construction methods through updated building norms, faster approvals and alignment with large housing, infrastructure and industrial development programmes. As Indian cities expand and demand rises from sectors such as manufacturing, logistics and data centres, construction solutions that reduce waste, improve execution speed and lower carbon impact are gaining stronger institutional backing. This policy support, combined with growing acceptance among developers, is expected to accelerate the adoption of wall panels across residential, commercial and industrial projects. Together, industry innovation and government initiatives are laying the groundwork for faster, more efficient and sustainable urban development in India.