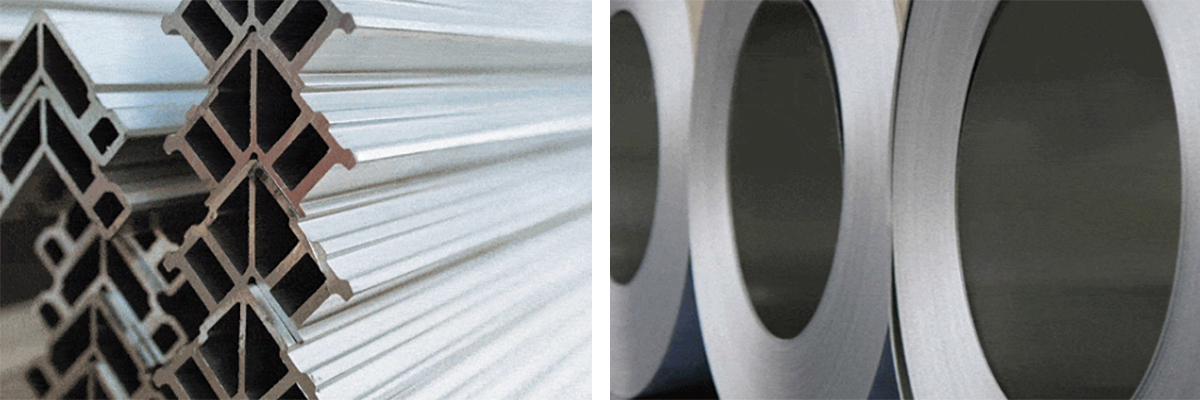

Jindal Aluminium uses 100% renewable energy at its manufacturing units in Bengaluru and Dabaspet, and was the first to set up wind power plants in 1997 in Karnataka. It is currently exporting its intricate aluminium profiles and other high quality products to over 45 countries. It undertakes continuous R&D to find novel uses for aluminium in different industries and in rising markets such as EVs, packaging, and batteries.

Jindal Aluminium has concluded a Rs 100 crore acquisition of Indo Alusys Industries Limited (IAIL-Bhiwadi) assets and announced commencement of production at the revived Bhiwadi unit in 2022. It is also adding further production capacities in the Bhiwadi unit, which, once fully operational, the company’s extrusion capacity is expected to increase from 1.30 lakh MTPA to 1.50 lakh MTPA. Jindal Aluminium is also the first Indian aluminium extrusion company with Hartford Steam Boiler (HSB) and ISO 9002/ IS/ISO 9001:2015) certification, and is also certified by the American Bureau of Shipping (ABS) for marine applications.