- By grinding and polishing with special diamond tools and treating with silicate hardeners ordinary concrete floors are converted into Polished Concrete Floors.

Flooring Requirements For Polished Concrete Floors.

- An essential prerequisite for doing Polished Concrete is laying a Flat Floor.

- Today all the equipment is available to lay flat floors (flex screeds, laser screeds etc) and these should definitely be used by the contractor if he plans to polish the concrete.

- Another requirement is that the grade of concrete should be at least M20.

- Grinding is not a solution for leveling uneven floors that are poorly laid. Trying to grind an uneven floor to achieve requisite flatness is a very expensive proposition.

- Not all concrete floors are “Polishable”. Contractors need to be able to make the distinction before taking a job.

- To reiterate, the concept of Concrete Polishing goes hand in hand with casting flat floors.

Figure 1: Grinding Machines

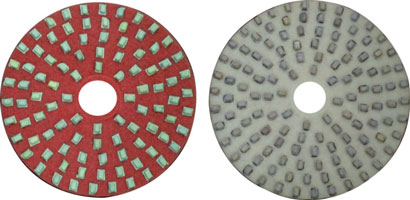

Figure 2: Metal Bond Diamond Tools

Overview of Procedure

- Dry Grinding with Metal Bond Diamond Tools

- Grouting

- Dry Honing with Resin Diamond Pads

- Densification

- Dry Polishing with Resin Diamond Pads

- Sealing with Top Coat

Grinding With Metal Bond

Figure 3: Industrial Dust Collectors

- We have a state of the art manufacturing facility in Himachal Pradesh.

- Metal Bond Tools are used for scraping, coatings removal and initial grinding.

- They are available in 6, 16, 25, 36, 60, 80, 120, 150 and 200 grit.

- Metal Bond Tools are available in Soft, Medium and Hard Bonds.

- Generally a hard floor requires a soft bond and vice versa.

Advantages of Dry Grinding

- Unlike Marble and Granite it is best to do Dry Grinding of Concrete Floors.

- Although Wet Grinding is possible the sheer quantity of sludge generated is a nightmare to handle on site. And with Dry Grinding, a lot of water is saved. Also, the operator can see results much better when the process is dry.

- Densification needs to be done on a dry floor and with dry grinding there is no need to wait for the floor to dry.

- By using a dust collector and special diamond tools Dry Grinding of Concrete eliminates all these practical problems.

Grouting

- Grouting is an essential step to repair pin holes and air pockets.

- Cement, latex and concrete dust (from the dust collector) are mixed together with appropriate quantity of water and applied on the floor to fill all the pin holes and air pockets that open up during grinding.

- Fast setting grouts cure in a matter of hours.

Densification

- Densification is the process of applying penetrating sealers that make concrete harder and denser.

- Silicates are used to densify concrete. Silicates react with the free limes (CaO) in concrete to form calcium silicate hydrate (CSH). The formation of CSH makes concrete denser and prevents dusting.

Advantages of Lithium Silicate

Figure 4: Resin Bond Diamond Pads

- Lithium is the most reactive. It also reacts evenly unlike sodium and potassium that leave unreacted free limes in the flooring.

- It has a greater depth of penetration as Lithium ions are the smallest.

- Unlike Sodium and Potassium the reaction of Lithium with free limes is non-expansive so it doesn’t lead to cracking.

Polishing With Resin Bond

- Resin Bond Diamond Pads are used for honing and polishing.

- They are available in 60, 100, 200, 400, 800, 1500, 3000, 5000, 8000 and 12000 grit.

- For concrete floors, 1500 or 3000 grit give a very high shine and the higher grits are not required.

- Again we recommend using Resin Diamond Pads Dry with a Dust Collector.

Sealing With Top Coat

- A Top Coat Sealer is a high shine coating that protects against stains and is wear resistant. It is done after 1500 or 3000 grit.

- It is applied with a microfiber mop and then burnished with a diamond pad at 1500 to 2000 rpm. This gives an excellent High Gloss finish.

- It is an optional step that can be done depending upon the client’s requirement.

Maintenance

After the concrete has been polished and the site is handed over to the owner it is important to help them set up a maintenance program. For cleaning, it is best to use a neutral floor cleaner and to maintain the shine all that are required are some Diamond Buffing Pads with some water. These pads fit directly under single discs and scrubber driers.Different Finishes

Figure 4: Resin Bond Diamond Pads

- Exposed Aggregate Polish - Aggressive grinding is done to expose the aggregates and then the concrete is polished.

- Salt & Pepper Polish - Medium grinding is done and smaller aggregates and the top peaks of the aggregates in the top layer are exposed and then the floor is polished.

- Top Surface Polish - Very light grinding is done and no aggregates are exposed. This is also called polishing the cream of the concrete.

- Honed Finish - This is similar to Top Surface Polish except that higher grit of diamonds are not used and it is a matt finish with a low sheen.

- Colored Concrete – Metal Oxides are added to the concrete mix. This type of coloring is permanent and basic metal oxides can be mixed to achieve different colors. This is a great way to replace traditional stone flooring such as Kota, Red Sandstone etc.

- Colored Concrete with Dyes - In the middle of polishing process colored dyes are sprayed onto the concrete to impart color. Used for interior applications.

- Acid Stained Colored Concrete - Instead of dyes, acid stains are used to color the concrete. Unlike dyes, acid stains react permanently with the concrete and are perfect not only for interior but also for exterior applications.

- Textured Finishes - Abrasive brushes are used in combination with diamond pads to create textures on the concrete floors.

Advantages of Diamond Polished Concrete Floors

- Increased durability & abrasion-resistance

- Makes the floors easy to clean & maintain

- Makes concrete dust-free

- Green technology - no need for expensive epoxy or polyurethane coatings

- Aesthetically pleasing

- Improved reflectivity

- Very long life & improved performance

- Saves time & money of laying tiles, carpets, marble or granite

Applications for Diamond Polished Concrete Floors

- Industries

- Warehouses And Warehouse Outlets

- Retail Stores

- Automobile Showrooms

- Hotels And Restaurants

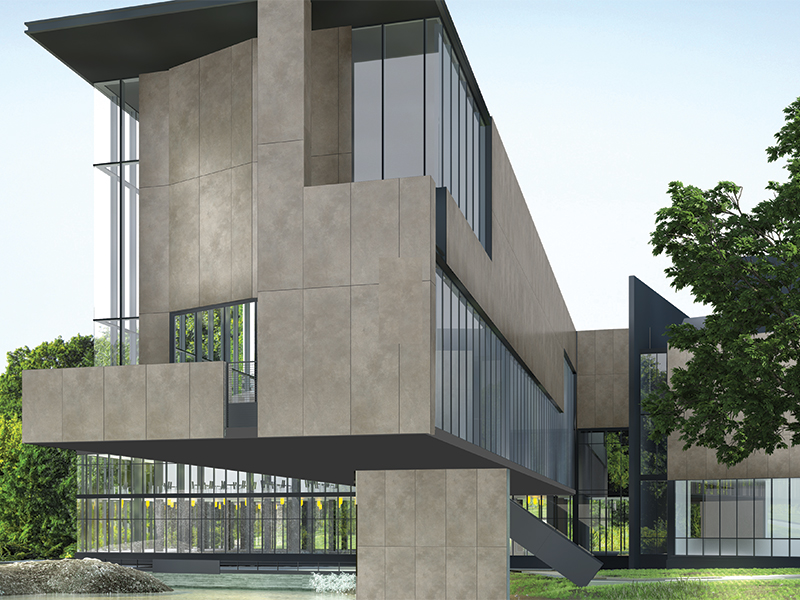

- Office Buildings

- Private Residences

Prestigious Projects

Some prestigious projects executed and under way with our Grinding Machines & Diamond Tools:- VW Factory Floor, Chakan, Pune

- TCS Project, Pune

- Asian Paints, Rohtak

- Ambience Mall, Gurgaon