Metal roofing is not a new concept in India receiving burgeoning response from the construction industry these days. Earlier, too, this roofing was found in many different structures. Till 2000, its use was limited to industrial structures, warehouses etc. But slowly and steadily as people becomes more aware of the benefits of metal roofing, it started making inroads in commercial structures like shopping malls, office complexes, resorts, farmhouses, railways, bus stations and now is also being used in residents.

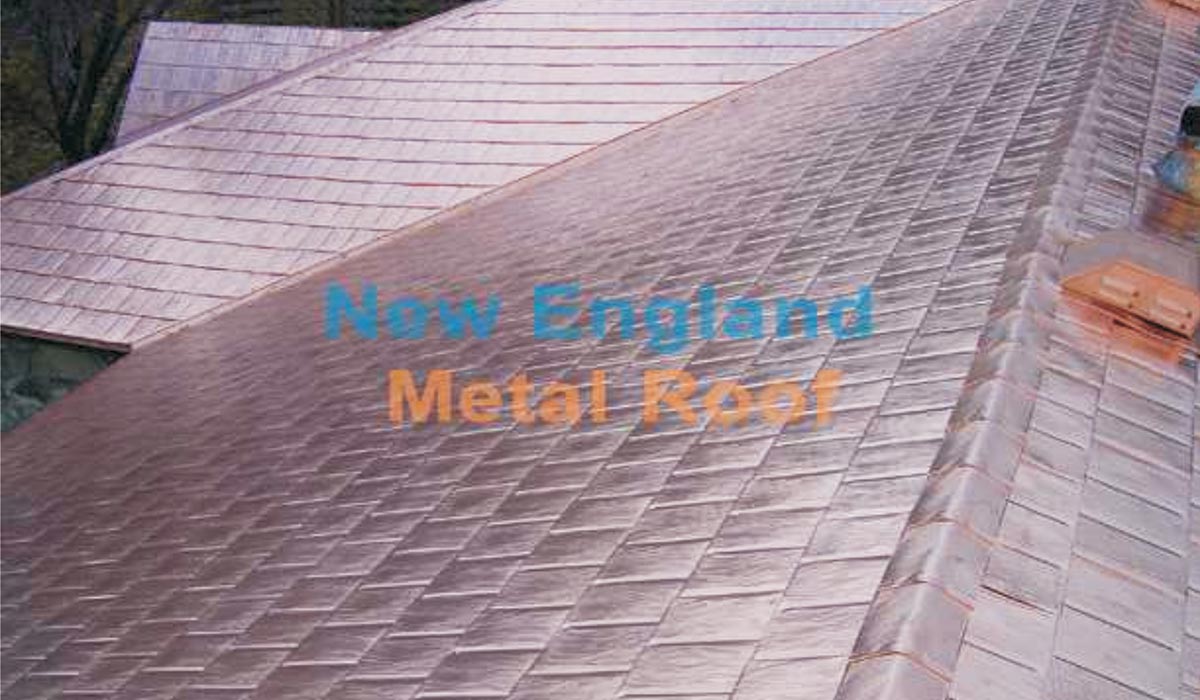

Metal Roofing is a very versatile, durable, easy to maintain and cost-effective building material. Metal roofs can be made from a variety of metals like copper, Aluminum, zinc or stainless-steel sheets that are environment-friendly and recyclable. Each of these metals provides a distinctive aesthetic look, and can be designed to suit various styles of roofing. Building owners cautious of green building technology and its benefits, often turn to metal roofing as a green roofing alternative for their existing roofs. Thus, the predominantly popular, asbestos, Ferrocement and asphalt shingle roofing are thrown out of the picture to make room for a much greener alternative in the form of metal roofing materials. Metal roofing material offer superior longevity, unprecedented reliability, unique appearance with a hint of beauty and modernity, significantly noticeable energy savings and last but not least admiration of your neighbors.

Modern Metal Roofing Alternative

In this article, some of the most popular metal roofing systems and materials available to building owners of restaurants, office buildings and other types of businesses are presented.Most modern metal roofing systems are available in galvanized, or galvalume steel, which is a great roofing material in terms of its price, relative weight and corrosion resistance properties. Other than this, Aluminum, on the other hand is perhaps the ultimate metal roofing material for any roof. It is very light weight and not a subject to the corrosion.

Copper, Tin, and Zinc are among other metal roofing materials to consider for your new roof. When doing your metal roofing materials research you may find that there are such exotic metal roofing systems as Titanium with intricate designs and hidden gutters. Clearly, such a metal roofing system is not a likely candidate to be your metal roofing material of choice. On the other hand, you might be pleasantly surprised that some metal roofing systems are quite affordable and offer great value. Not only that, metal roofing systems such as standing seam roofs, can be outfitted with solar roofing panels and provide your building with Solar derived electricity! How cool is that? Certainly cool from green building perspective.

As far as metal roofing system design is concerned, you are free to choose from metal shingle roofing systems with interlocking design, metal shakes, standing seam, batten seam, simulated Spanish tiles, be it painted roofing panel, or Stone coated / granule coated steel, simulated slate, and metal tiles. Regardless of the metal roofing system be sure to check with metal roofing manufacturers' requirements for suitability for your roof, and availability of materials in case the need for roof repair ever arises.

Now that we sort of have covered metal roofing material basics, let's get to a more systematic look at some of the popular metal roofing systems and materials they are available in.

There is a big important distinction between metal roofing systems, which constitutes roof system design, system components and flashings, appearance, reliability and ease of installation, and the actual metal that the given metal roofing system's materials are made out of, which is essentially responsible for the cost, longevity, and plays an important role in determining the appropriateness for a specific use, which will vary depending on your situation or project requirements.

Standing Seam Metal Roofing

This type of roof is one of the most widely used types of all metal roofing systems. Standing seam metal roofing panels are available in architectural and commercial system designs and styles. It comes with concealed and exposed fasteners. Concealed fasteners offer higher reliability and lessen the chance of a roof leak. Standing seam roofing offers great advantages over asphalt shingle roofs. For example, standing seam metal roof that was installed correctly and in accordance with manufacturer's specifications can last a really long time, providing reliable and maintenance free protection without the need for costly roof repairs. It provides modern look for the building makes a green statement about the owner and compliments the beauty of the building. In fact, many architects choose metal roofing precisely because of the modern looks and feel of technologically advanced roofing system. The initial higher cost of investment is offset by the visual appearance and boldness of straight lines and use of metal, excellent reliability with proven track record, energy savings, and prevention of ice dam build up issues. Many standing seam metal roofs can also be outfitted with thin film solar metal roofing panels taking your roof's energy efficiency to yet another level. Standing seam can be used in retrofit and new construction applications. I do not recommend using standing seam metal roof on cut up roof with multiple skylights, dormers, and level changes because, every change in length of the panel to account for changes in roof terrain will amount to a large amount in labor, which will drive up costs through the roof, and can hinder the overall quality because of the likely installer's error due to heightened complexity. Standing seam is the type of metal roofing system that can be easy to install on straight runs with simple roof structures such as gable roofs. Should your roof be extremely cut up, I would recommend using Aluminum shingle roofing, which will work well for a complex roof. The reason for a versatility of Aluminum shingle is its small panel size that can be compared to building a highly complex home, roof, and what not out of the small Lego pieces in the form of Aluminum shingles.Green Standing Seam Metal Roof

Choice of metal material for standing seam metal roofAluminum, which is a permanent metal that is not subjected to corrosion from being exposed to the elements, can last an infinite amount of time provided that the metal roof was installed correctly with respect to water tightness and roof ventilation. It is very lightweight and flexible metal that can withstand salty environment, and strong wind uplift. Aluminum standing seam would make for a perfect metal roof around coastal areas where less expensive steel could eventually fail to the corrosion due to high concentration of salt in the air. Steel can be a slightly less expensive metal roofing material of choice when the roof in question is not in close proximity to the coastal area. Modern day steel metal roofs are protected / coated with layer of Zinc and Aluminum, which provides protection from the elements in the environment and helps prevent corrosion. Thus, steel is generally safe for use in roofing applications and can last a very long time given that it is also protected with a quality paint finish such as Kynar 500, the industry standard, or better. Copper, the ageless beauty of copper is an expensive investment, but if money is not an issue then the visual appeal and longevity will bring great amount of satisfaction, longevity, and compliments form your neighbors.

Standing Seam for low Slope Roofs

Typically, a snap lock profile of standing seam is used in residential roofing applications. Snap lock refers to aligning the panels together, with the locking mechanism over the preceding panel and then gently taping over the panels, until it snaps into place. The snap lock based design standing seam can be used on roofs with pitch of 3 to 12 and higher. For lower slope roofs, a mechanically locked standing seam roof system should be used. Refer to the specific Metal Roofing manufacturer's specifications on the use of any given metal roofing system and materials.Metal Shingle Roofs

Most Metal Shingle roofs require a minimum roof pitch of 4 to 12. They typically feature interlocking design and are fairly easy to install because panels can easily be adjusted for changes in roof patterns.

Custom Metal Roofing Systems

Every once in a while, there is a need for a custom build metal roofing materials that can meet architect's specifications for wind uplift, environmental factors and style. There are smaller metal roofing manufacturers who are willing to adapt to your needs. Picture illustrates custom metal roofing system comprised of blue color metal shakes.Custom Order Metal Roofing Materials

When you finally decide on the type of metal roofing materials you want to use for your projects, be sure to check with manufacturer that your roof is suitable for the metal roofing materials you would like to use. Factors to consider would be pitch, metal type used, and system specific installation requirements.Building owners can learn more about Metal Roofing Systems on.

http://www.newenglandmetalroof.com/ from where the article has been reproduce with the kind permission.