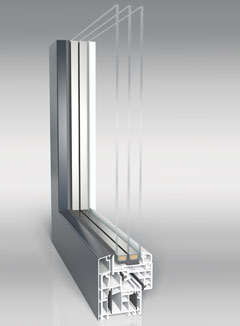

Pointing out the aesthetic part, he said, "The 'Swiss' false mullion with its slim visible width of only 109 mm complements the delicate appearance of energeto® 5000 view. powerdur inside (fibre-reinforced profiles) and bonding inside (gluing the glazing to the rebate) render steel reinforcements unnecessary, and allow for excellent insulation values. Thermal insulation can be optimized even further with the optional technology foam inside (using insulating foam)."

Mr. Feldmann added, "The highly-demanded aluminium look can be realized easily as no aluminium shell is needed for the sash and for the frame the false mullion and mullion can be retrofitted with aluminium shells after the mass production process is completed. This additionally simplifies processing. In addition to the mitre-cut aluminium shell, aluplast again offers the butt-jointed version. The overall design of the aluminium shells remains unchanged, so that energeto® 5000 view can be combined perfectly with aluplast residential and lift-and-slide doors. The aluminium shell can be powder coated in any colour which can be done in India itself. Due to itshighly attractive design we recommend this system especially for hotels, resorts as well as hospitals and clinics. Itsenergy efficiency as well as sound insulation makes it an ideal fenestration choice for such ambitious building projects."

Talking about the Indian uPVC window system market, he said, "The market is becoming competitive, reflecting the increasing acceptance of uPVC window systems. Though, aluplast remains in the top 10% of the market range, we think it's good to have competition as it will lead to differentiation and improvement in the quality, besides increasing volumes, minimising lead time, delivering quality services, etc. This will also increase the options for the customers to compare and opt accordingly. We expect our customers to choose from among the top players for they have the quality that can withstand the harsh Indian weather and provide longevity."

Speaking on the style of working, he said, "alupalst India works in close coordination with its clients – individual (retail) or builder (project). We supply the same quality products to both types of clients – retail or project. We do not really differentiate on the basis of quality to bring the prices down. Actually, price depends largely on the nature of the solutions that we offer which also involve various level of services needed to explain the nuances to a client. When we sit together with the specifiers, we develop design that can help optimize the wastage and thus we save the cost for our clients.Of course, when it comes to retail customers, more explanation is required to satisfy their individual inquisitiveness. The process asks for quite a few sittings, which in turn add to the cost. This is not the case with the project buyers. When we sit together with the specifiers, we develop design that can help optimize the wastage and thus we save the cost for our clients."

Anticipating the future, he added, "We are very positive about the future of aluplast in Indian market. We already have completed quite a few big projects in India and are also engaged in a few more. We have about 20 fabricators spread across the country. As far as the potential is concerned, for any premium quality product like ours the opportunities always lie in the metro so there are people who want to invest in these luxuries and also they have the money to pay for the same. We are leading in north and in the process of filling the south as well."