What factors are driving the market for coated steel and related building products in India? How has this impacted the growth of Tata BlueScope Steel products?

The growth prospects of the Indian steel industry are quite good because, today, India is seeing an overall growth, inspite of the world grappling with geopolitical tensions, economic slowdown, rising food and energy prices, and the long-term ill-effects of the pandemic. India assuming a year-long presidency of the G20 on December 1st reflects the confidence that the world has in us and the opportunities that lie ahead. This would definitely act as a catalyst for investment opportunities and sustainable growth.

Moreover, being the world’s 5th largest economy; we are truly poised for the next level of transformation where we would witness India growing as a manufacturing hub. With the Government’s push on infrastructure projects, our country is undergoing a fast-paced transformation. Given the slew of ongoing and planned infrastructure projects ranging from construction of highways, rail lines, metros, and airports, we will witness a greater demand for steel, especially within the roofing and cladding industry. The “Make in India – Make for World” initiative will further boost growth in homegrown enterprises, including textile parks, pharma parks, and agro-processing units, to name a few.

What are the wider application areas of coated steel?

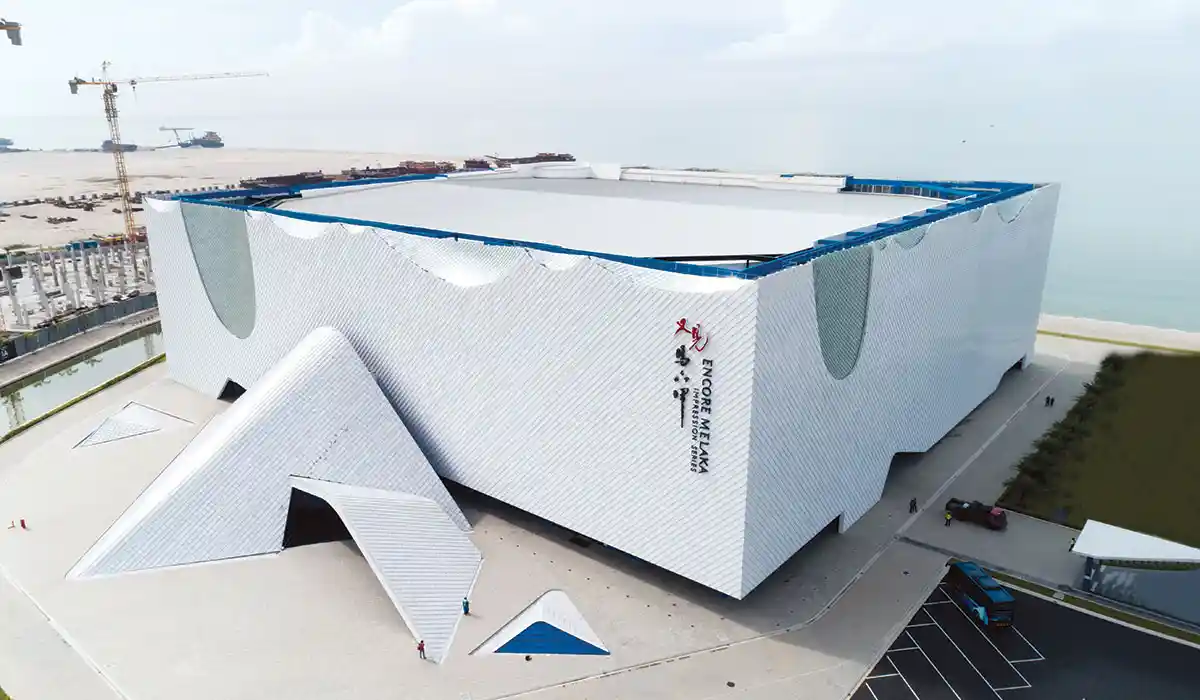

A growing interest in sustainable, low-maintenance, and durable roofing material is further accelerating the adoption of coated steel in roofing and walling application in builidng and constuction segment. Thermally efficient roofing system with green credentials is the future of construction.

Tata BlueScope’s COLORBOND® steel is the best choice of architects, designers, and building owners because as a roofing and walling material it meets the need for longevity, aesthetics, cool comfort, besides being recyclable

Vikas Pundir

Majority of the coated steel products are used in roofing and walling application typically in Pre-engineered metal buildings, conventional buildings, Highrise steel buildings. other than roofing and walling application, coated steel is been preferred in alternative application such as solar farms, grain silos, big size liquid steel tanks, structural purlins/ girts, LGFS, ceilings, pipe jacketing and appliance manufactured articles etc.

Applications include:

- Alternate applications such as silos and liquid water tanks

- Solar structures (ground and roof mounted)

- False ceilings

- Racking systems

- Light gauge framing system (LGFS)

- Refineries - pipe claddings

- Home appliances, bus bodies, and furniture (to name a few).

Tata BlueScope coated steel products are offering design flexibility, high strength, and high resistance to corrosion , helps to enhance the building longevity when it used as part of the cladding material. Having high-quality COLORBOND® steels pant system over ZINCALUME ® steel substrate increases the corrosion protection and adds up the aesthetics to the building’s appearance. Tata BlueScope coated steel products require minimal or zero maintenance and provide cool comfort in hot weather (lower roof temperature by up-to- 6 deg C). COLORBOND® steel paint system uses high infra-red reflective pigments which increase the Solar Reflectivity - Thermatech solar reflectance technology. When a roof has a high SRI value, you will save electricity consumption by up to 15%. With coated steel’s high strength to weight ratio, you can save steel consumption by up to 20% in comparison to ordinary grade of steel.

In case of safety of the building (which is the primary goal of any building), steel is the best material as it provides most of the safety benefits. Steel is non-combustible, does not ignite or spread flames, and is resistant to rust and corrosion when properly coated. Roofs do not usually need to provide any period of fire resistance, but they must be designed to prevent the spread of fire.

How is the use of coated steel contributing to sustainability in construction?

Tata BlueScope’s COLORBOND® steel is durable and resilient in harsh climate and its long life helps conserve resources and energy that may otherwise be invested in products with a shorter lifespan. COLORBOND® steel is 100% recyclable. In some cases, it can be reused without reprocessing, again saving on energy and resource use, and can help in meeting many green building requirements.

What are its characteristics that make COLORBOND® steel a green product? How relevant are eco-label certifications for asserting leadership in sustainability and how do customers benefit by them?

Our manufacturing facility is located in a radius qualifying as regional materials for use in most of the project sites in India. Many light shades of COLORBOND® steel meet solar reflectance index (SRI) required by green building standards.

Since the steel is pre-painted, it does not have to be painted at the construction site. It is likely to emit zero or less TVOCs and formaldehyde than other materials used for the same purpose, which means better IAQ and health benefits to the building’s occupants. A COLORBOND® steel roof is suitable for Rainwater Harvesting as the external coating is free from heavy metals like lead content, Hg, Cd, etc. COLORBOND® steel has the following well-known eco-label certifications which establish it as a leader in sustainable architecture:

- GRIHA (Green Rating for Integrated Habitat Assessment) product certification in Metal Coated Steel & Color Coated Steel.

- Recognized by CII Indian Green Building Council (IGBC) as Green Product in Green Building Ratings.

- Published Environmental Product Declaration (EPD) – the first of its kind within the product category.

Please throw some light on the recently published Environment Product Declaration for Coated Steel Plant.

Tata BlueScope is India’s first company to publish EPD for its coated steel products manufactured from its Jamshedpur plant for roofing and wall cladding applications. EPD provides the foundation for assessing buildings and other construction works and identifying that cause less stress to the environment.

EPD also serves as a reliable source of information comparison and selection of suppliers. It not only communicates accurate environmental information for products and their applications, but also supports scientifically-based, fair choices, and stimulates the potential for market-driven continuous environmental improvement.