Textures, colors, and designs that can be produced in precast technology

With precast technology, the potential for textures is extensive, offering a choice of smooth surfaces or even the creation of patterned walls. In fact, we have created patterned walls for SOBHA Sentosa a luxury property in Bengaluru, using precast technology. To further enhance the aesthetic appeal, form liners are used to impart captivating patterns on facades, without hampering structural integrity.

The flexible color palette that can be used for exterior walls allows designers and architects with significant to try different styles, allowing them to push the boundaries of conventional design. By embracing this technology, developers have the inherent advantage to create buildings that are not only functional but also visually captivating, ushering in a new era of effective and compelling architectural design.

Lifespan of precast construction vis-a-vis buildings of traditional construction

Evaluating the lifespan of precast construction in comparison to traditional construction methods is a challenge as the disparities may not be easily visible. However, it is worth noting that precast technology offers a slight advantage in terms of quality due to the factory-controlled manufacturing and finishing processes employed for precast elements.By leveraging the advantages of precast technology, real estate developers can offer structures that not only show exceptional craftsmanship but also complete construction faster by about 15%.

Precast concrete is pushing the boundaries of conventional design, allowing designers and architects to try various captivating styles and designs.

Arun Kumar - Senior VP, Architecture, Sobha Ltd

Pushing the boundaries of construction possibilities

How high can precast buildings go up to? As a forward-thinking real estate company, we recognize that the sky is the limit when it comes to pushing the boundaries of construction possibilities. At the same time, there can be no right answer as to how high precast buildings can go, as it depends on a range of factors, such as the availability of infrastructure like cranes and associated skilled manpower and capabilities. Ready-to-fit compound walls

Ready-to-fit compound wallsChecks to ensure quality and stability

Both quality and safety rank high in SOBHA’s quest for excellence. Having the highest standards of quality and safety have ensured SOBHA diligently checks for both parameters through its own robust and time-tested quality and safety processes and standards. So, structural integrity along with meticulous designs that adhere to prevailing structural codes, taking into careful consideration seismic and other pertinent aspects, is how SOBHA ensures the highest safety standards across its portfolio. The design process involves rigorous scrutiny and thorough vetting by institutions, including renowned establishments such as IIT.Precast a viable option for villas and hotel resorts

In real estate, precast technology is a highly viable option for constructing individual villas and hotel resorts. This innovative approach to construction offers many advantages, including accelerated construction timelines and enhanced quality control, surpassing traditional cast-in-place concrete methods. By leveraging precast construction techniques, developers can significantly speed up the construction process without compromising on the quality of the final product.Along with strength, durability, and design flexibility, the most desirable quality in any construction material is its customization potential.

Sneha Gurjar - Director, CEM Engineers

Precast concrete is widely used in various large-scale projects since it is a mobile material cast in one place for use elsewhere. Contrary to assumptions about the economics of precast concrete, depending on the scale and intention of a project, precast technology offers many advantages, including a reduced construction period, cost efficiency, quality control, fast and accurate erection of members, and environmental protection.

Being highly cost-effective and time-efficient for large-scale industrial projects, precast concrete construction in India is being used to construct dams, coastal structures, marine structures, bridges, culverts, tunnels, retaining walls, noise barriers, highway pavements, affordable housing, and other modular structures.

Precast concrete enables architectural panels to be made in large numbers off-site while other construction tasks can be completed on-site. This means buildings can go up quicker and cheaper while maintaining architectural integrity and aesthetic.

This precast innovation was first introduced in the early 1900s. Today, some precast concrete is available in standard shapes and dimensions, such as floor and roof planks. Precast concrete may otherwise be fabricated in any shape and size consistent with the bylaws, the strength and stiffness of the materials, and the constraints imposed by formwork, transportation, handling, and erection.

Its ability to fit and mould into any form of design offers a lot of room for creativity and flexibility for designers and architects. And due to the inherent structural capabilities of precast, structures can also be designed for practically any soil or seismic condition. Precast concrete allows limitless customisation options and reduces the time taken for in-situ concrete construction and the safety factors involved in its assembly.

Precast concrete construction is a viable construction alternative in the country today.

Sameer Divekar - Executive VP, CP Kukreja Architects

Precast concrete construction is a very cost-effective method provided it is employed correctly. Besides saving building materials, it also enables faster execution. The technology is preferred in construction projects that involve a modular design, for example, bridges, mass housing projects, etc. Since the arrival of precast concrete technology, such projects have experienced a significant increase in their pace of construction

More than creative design flexibility, precast construction offers the flexibility for modular design alongside facilitating faster construction. In this fast-paced era, there could be no better alternative than the one that gets the job done quickly and saves time - the most precious resource. Our upcoming project CPCL Township in Chennai uses Precast concrete construction technology.

At Eros Group, we take pride in our expertise in precast construction and are pleased to adopt this technology for the scope it offers in creative design flexibility amongst many other benefits. Precast construction is a revolutionary method that enables architects and builders to push the boundaries of design innovation and efficiency.

Avneesh Sood - Director, Eros Group

First and foremost, precast construction allows for intricate and customizable design elements. Precast concrete components can be moulded into a wide array of shapes, sizes, and textures, offering architects immense creative freedom. Whether it’s intricate façades, decorative panels, or unique structural elements, precast concrete can be tailored to meet the most demanding design requirements. Moreover, the versatility of precast construction extends to various architectural styles. Whether your project demands a sleek, modern aesthetic or a more traditional appearance, precast concrete can be adapted to suit any design vision. Its adaptability also extends to finishes, with a range of options from exposed aggregate to polished surfaces.

Beyond aesthetics, precast construction offers efficiency and sustainability benefits. Its factory-controlled production minimizes waste, and enhances quality, reducing construction timelines and costs. Precast components are durable and low-maintenance, ensuring long-term sustainability.

Precast technology offers flexibility in design, enables faster completion, and gives consistent high quality to the project under construction. By leveraging precast technology, high-rise buildings can be constructed with optimized cost-efficiency, delivering value to both developers and investors.

Suhas Mohol - Managing Director, StruEngineers India

Important aspects in high-rise construction using precast technology

A representation of a high-rise building using precast concrete technology. From far it is nearly impossible to distinguish a precast building from a conventionally constructed one.

A representation of a high-rise building using precast concrete technology. From far it is nearly impossible to distinguish a precast building from a conventionally constructed one.Safety is of paramount importance in high-rise construction due to the complexities and challenges involved in erecting tall structures. High-rise buildings must be designed and constructed to withstand various forces such as wind, seismic activity, and the vertical loads imposed by the structure itself. Implementing appropriate safety measures, using high-quality materials, adhering to building codes and regulations, and conducting thorough inspections are crucial to ensure the safety of the building, workers, and occupants. Additionally, precast elements can be designed with built-in safety features, such as fire-resistant materials and seismic reinforcement, ensuring the structural integrity of the building during unforeseen events.

Numerous high-rise buildings worldwide have been successfully constructed using precast concrete elements. For example, the Aqua Tower in Chicago, USA (82 floors), Pearl River Tower - Guangzhou, China (71 floors), The Gramercy Residences - Makati, Philippines (73 floors), Bahrain World Trade Center - Manama, Bahrain (50 floors), Palais Royale - Mumbai (88 floors), Supernova Spira - Noida (80 floors), and The Park – Kolkata (27 floors).

Cost saving advantages

The initial stages of a precast construction project. The flooring slab elements joined together and the wall elements are ready to be assembled.

The initial stages of a precast construction project. The flooring slab elements joined together and the wall elements are ready to be assembled.Design and sustainability benefits

Precast concrete is highly adaptable to diverse architectural designs. It allows for intricate shapes, textures, and finishes, enabling architects to unleash their creativity and bring unique visions to life. Precast panels, beams, columns, and facades can be customized to match the desired aesthetic appeal, creating stunning high-rise structures that stand out in the skyline.In an era of increased environmental consciousness, precast concrete offers sustainable advantages. The manufacturing process generates less waste and reduces on-site construction waste. Additionally, precast elements can incorporate recycled materials, further minimizing environmental impact.

With ongoing advancements, we can expect even more remarkable developments in the realm of precast construction, paving the way for taller, greener, and more visually stunning buildings in the future.

Assembling wall elements at a precast construction project

Assembling wall elements at a precast construction projectBIM Software helping structural engineers

Precast concrete technology enhances efficiency, reduces costs, and expedites project timelines. Since the components are manufactured in specialized factories in a controlled environment, it ensures high quality and precision of the precast elements, which are then transported to the construction site and assembled. Today, most of the big builders are using precast construction. Top view of a high-rise building designed in IMPACT. Each slab element is represented separately. In the actual construction, no such separation is observed as the joining, grouting, and the screeding processes make the entire structure look homogenous.

Top view of a high-rise building designed in IMPACT. Each slab element is represented separately. In the actual construction, no such separation is observed as the joining, grouting, and the screeding processes make the entire structure look homogenous.Another major reason why builders are opting for precast technology is the rapid progress made in the field of Structural Engineering, particularly in conjunction with Precast Building Information Modeling (BIM) software, which has significantly contributed to the progress and acceptance of precast technology. Structural engineers can now simulate real-life conditions and analyze the impact of wind forces, seismic forces, other natural forces, as well as the various loads acting on the building elements, including the structure’s dead weight.

This advanced software enables precise data collection, leading to meticulous design and detailing of precast elements well in advance of on-site activities. Simulating and optimizing structural performance prior to construction reduces errors, enhances safety, and streamlines the overall construction process.

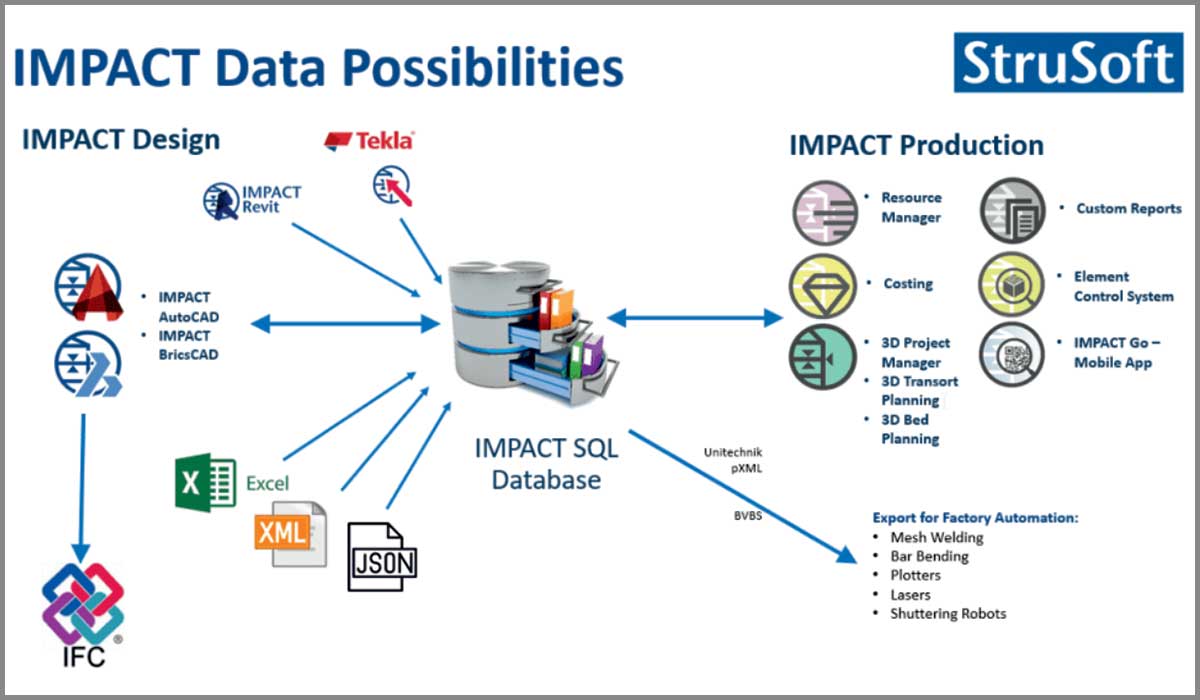

StruSoft IMPACT is a comprehensive and user-friendly BIM platform specifically designed for precast concrete technology. It offers an integrated solution for Designers, Architects, Consultants, Precast Manufacturers, Builders, Quality Control and Logistics personnel. It streamlines the entire precast supply chain, providing functionalities for designing, detailing, project management, and logistics coordination. Users can effortlessly design and detail precast elements while effectively handling multiple projects across different locations.