APL Apollo has revolutionized the Steel Tubes and Pipes manufacturing industry

APL Apollo has maintained a dominant position in the branded structural steel tubes market. From establishing its first manufacturing plant in Sikandarabad in 1986, the company is now the largest producer of ERW steel pipes in India, with an installed capacity of 2.55 million tons.

APL Apollo has a pan-India presence with 10 manufacturing facilities: 4 near Delhi-NCR, 3 in Bangalore, and one each in Raipur, Murbad and near Mumbai, and warehouse-cum-branches in over 20 cities. We have a typical B2C franchisee model wherein we sell our goods to around 800 distributors, who in turn sell to 50,000 retailers, who further sell to 200,000 fabricators.

APL Apollo has broken the mould by manufacturing square and rectangular pipes

APL Apollo has been a pioneer in researching, producing, and launching a range of futuristic products in the market. Its tubes and pipes are seen as tough, utilitarian, environment-friendly and scalable. Our square and rectangular pipes have a better load-bearing capacity, even for huge structures, and are replacing the conventional steel products.

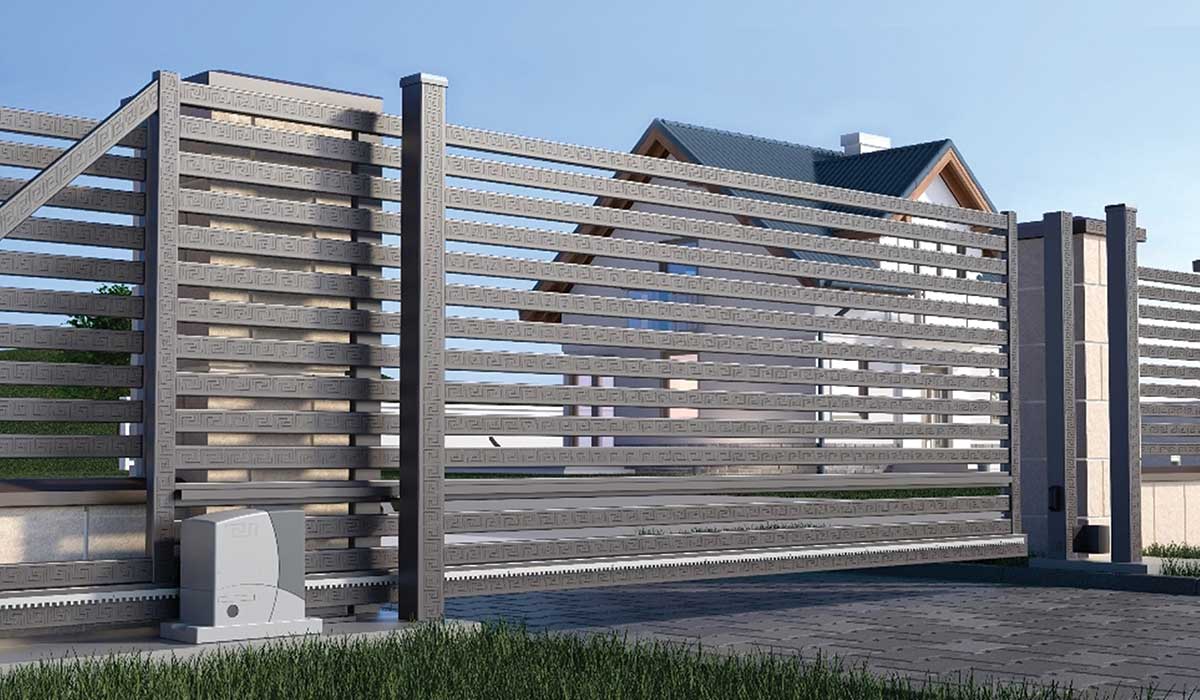

APL Apollo has come up with a wide range of designer galvanized pipes

The company is engaged in developing high diameter, high thickness steel tubes and has been successfully replacing the five conventional structural products such as steel angle channels, wood, aluminium, concrete RCC, and long steel products, including metal plates, with its extraordinary products in this segment.

APL Apollo’s designer galvanized pipes are an upgrade of the conventional steel pipes by virtue of the engraved designs on them. To meet the fast-growing demand in the interior design industry, APL Apollo has launched ‘Apollo Signature’, an attractive collection of designer pipes with special embossing for modern, stylish structures.

Apollo Column is India’s largest range of square hollow steel sections (HSS); these have emerged as the preferred choice in every type of construction, especially in the Pre-Engineered Buildings segment, where it has become an essential feature due to its high weight bearing capacity and enhanced speed of construction.

APL Apollo has been successfully replacing the five conventional structural products such as steel angle channels, wood, aluminium, concrete RCC, and long steel products, including metal plates, with its extraordinary products in this segment. It has also come up with a wide range of galvanized pipes with engraved designs and special embossing for the interior design industry. Apollo’s square hollow steel sections (HSS) are the preferred choice in every type of construction, especially Pre-Engineered Buildings, due to their high weight bearing capacity and enhanced speed of construction.

Sanjay Gupta

We are exporting to over 20 countries globally

APL Apollo has achieved the Recognized Export House status and is also ISO 9001:2008, ISO 14001:2004 and OHSAS 18001:2007 certified. Our products are BIS marked and certified by reputed international agencies like SGS (France), CE (Europe) etc.

We are the largest producer of Electric Resistance Welded (ERW) steel pipes and tubes in India and are exporting to over 20 countries globally. We are also the fastest growing pre-galvanized steel tubes and pipes manufacturer and exporter in India. The company has been awarded patents for six product designs: Handrail, Narrow Section, Window L Section, Window T, Window Z and Elliptical Tube.

We carry out comprehensive quality checks and tests at all stages of product development

In order to ensure that our end-product is both durable and safe for use, we carry out an ABC analysis, which comprises of a graphical comparison of production parameters with standard norms. We carry out comprehensive quality checks at all stages - from raw material procurement to the end product and ISI-marked delivery – including tests to measure hardness, flattening, tensile and drift tests, among others.

Moreover, we have an online non-destructive testing system (eddy current testing) to check tube defects like cracks, pinholes, open welds, voids, inclusions, concentrated porosity, weld defects, mechanical damages, opened-up skin laminations, deep pitting, and parent material defects. We have strengthened our quality management system further by outsourcing different kinds of checks from NABL and other approved labs.

APL Apollo has launched revolutionary products with a futuristic vision of making roads safer and to enhance landscapes

The company is a major provider of tubes for road delineators used in dangerous curves, tunnels, bridges, and parking lots, etc. APL Apollo’s aesthetically advanced and highly durable H-section Oval for road safety and fencing provides better visibility on turns. The company also offers parking barriers and a range of fencing solutions.

Our focus has always been to bring-in the most advanced and research-led products for engineers and architects to help them ace the art of construction.

India has witnessed considerable progress in construction technology and solutions for infrastructure development

Infra and real estate construction is undoubtedly among the topmost priorities of the country in view of the government’s ambitious schemes of 100 smart cities, metro projects, and, above all, Housing for All.

The construction industry in India is undergoing revolutionary changes in terms of building technology, state-of-the-art machinery, and advanced building materials. Artificial intelligence has also transformed the industry with better planning and by helping in designing smart/tech-enabled cities. Especially, the real estate and infra sectors, which are fast adopting technology across the supply chain and for enabling more efficient and transparent operations, so much so that digital technology is being increasingly utilized for speedy delivery of projects.

APL Apollo, like most of the frontrunners in the industry, is already in the process of adapting to significant changes to embrace Industry 4.0 transformation. We understand that adoption of technologies such as AI, IoT and Cloud in the manufacturing industry will unleash the next digital revolution that will help India meet its sustainable development goals.