Tensile Architecture - Today's Fabric for designs

Tensile architecture has a long standing history and is probably one of the oldest methods of architecture. The primitive man used to make tents out of animal skins later on incorporating woven fabrics. A classic case of Tensile Architecture in history is that of Roman Amphitheaters where the roofs were erected with retractable sheets of fabrics supported by timber masts and cotton fiber ropes, like the ones used by sailors.The different forms developed over time, using more advances material and construction methods into large and more diverse structures.

New materials for tensile architecture offer architect an opportunity for designing any shape in 3 dimensions which is generally not possible with other forms of architecture.

PVC coated tensile membranes have the flexibility of form, that sets them apart from any other conventional building material, both from an aesthetic and a functional point of view. The free-flowing, organic forms achieved by these structures are physically unachievable by the much more rigid structures.

Tensile structures are unique by the combination of their specific physical, technical and geometrical characteristics and can be designed as permanent, temporary or even portable structures. Permanent structures can also be installed as retractable roofs, e.g., to cover open-air theatres.

Tensile structures can be designed for an endless range of applications that leave both an exciting and original architectural landmark. Tensile structures are not only light, elegant, and translucent but also durable and often economical, over large spans. All of these characteristics give designers and architects an unequalled and almost unlimited aesthetic potential to explore fabric forms, and to integrate them with their architecture.

Innovative, Tractile, and Versatile Tensile!

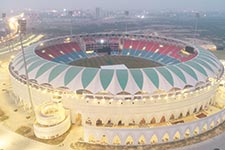

When tensile structures are used and designed effectively, they can create certain fluidity and a lightness that is not easily achievable in concrete and steel.From being relegated to only lawns and verandah roofs, a few years ago, tensile elements are now being used, to encompass entire buildings and large spaces within them. The roof at 'Beijing Velodrome" and the cantilever roof at Dr D Y Patil Cricket Stadium are erected using PVC Coated membranes from Mehler Texnologies. Sails Sculpture at dam wall at Amby Valley is a classic example of creating beautiful and aesthetically pleasing structures. Advent of new technologies have allowed tensile fabrics and structures, to create very exciting possibilities in architectural design, providing an entirely different canvas to work with; rendering themselves to endless creative experiments in designing form and space.

Mehler Texnologies GmbH, headquartered in Hückelhoven Germany, and with offices all over the world, is one the pioneers in the field of manufacturing membranes for Tensile Architecture. The company began its initial operations in 1944 with the coating of PVC-Polyester membranes and was 'one of the first' to improve the special PVDF lacquering techniques, today synonymous with long-term cleanability and added long term UV protection. The company has since acquired a wide range of expertise and experience in the field of membrane architecture materials with thrust in textile products.

Mehler enables architectural wonders that use modern fabric materials; these can shape space, allowing architects to sculpt 3-dimensional areas in a manner that is not possible with any other type of material. This kind of architecture allows the designer to play around with light and use this for natural illumination of the space, softening it, fusing it, sharpening it or shaping it. This creates the mood and ambiance, to reflect architectural intent, resulting in an energy saving covering system, by using the elements of nature. The dynamic shape and form of membranes translate unconventional architectural dream, to reality.

In no other sector of architecture do form and load distribution depend on each other as greatly as they do in membrane construction; thus interfacing elements of architecture and engineering.

A glimpse of the Mehler strength

- 50 million m2 fabrics under the brand names VALMEX®, POLYMAR® and AIRTEX®.

- Approx. 600 employees worldwide

- 3 production facilities

- 9 sales companies

- 7 sales offices and sales partners around the world

Architectural Materials from Mehler

In the architectural segment, membranes made by Mehler Texnologies are multi-layered composite materials with special densely woven low-wick yarns in base fabric. The VALMEX® structure materials are manufactured with a double thread woven fabric, commonly described as "Panama" weave, varies depending on the mechanical resistance requested by the customers. The different membrane materials are graded by weight and strength.Mehler's materials are basically 'pre - stressed' with different force grades in both directions. The warp direction (length of the material roll) has less stretch to stabilize the elongation in this sense. The weft direction (the width side of the material roll) has more stretch in order to absorb the orthogonal tension more readily during the distensile installation process.

The Mehler- layer add, is the value-add

Mehler's PVDF coated fabrics, incorporate a primer between the top coating lacquer and the PVC coating, completing 5 components in building up of the product. The appropriate thickness of the lacquer protects fabric from 'peeling effect.' Hence Mehler fabrics are weldable, easy to use, and durable (non-peeling) in nature. It is important to mention that Mehler membranes are lacquered on both sides. They can get HF-welded directly without grinding. To grind a membrane reduces the thickness of the PVC coating and causes the risk of damaging the base fabric.In tensile architecture, where the absolute concept of 'less (weight, mass, emissions, etc.) is more', there is an increasing demand for and growing popularity of weldable PVDF coated fabrics from Mehler.

Is lacquering a matter of quantity?

In fact, it is all about quality. It involves a carefully monitored and controlled process that results in optimal and uniform thickness of the coating, which in turn enhances the fabric quality.Mehler has, after years of relentless research and intense dialogues with planners, manufacturers and processors in different market segments, industry users, and designers, perfected the process of lacquering. Improper lacquering can result in uneven translucency, causing stiffness, leading to peeling and cracking of the PVC coating and exposing the fabric directly to UV attacks causes soiling and degradation.

Hence, the salient features of Mehler's coating materials can be summarized as cost - effective, quality - norm - compliant, weldable, foldable, tensile, easy to install; weather, wind, and fire resistant. They come in vibrant colors as well as clear white color; versatile in applications, low maintenance cost, very durable and hence dependable.

It should also be mentioned that VALMEX® structure membranes are (mechanically) recyclable.

It is apt to quote the award - winning ace architect and the man behind the awesome design of the residential skyscraper 'Waves' at Worli Sea - face, Mumbai, Sanjay Puri, "Innovative use of tensile forms, frees architecture from the relatively static nature of concrete and steel, allowing its spaces to be perceived more fluidly and dynamically."!