| Project brief: | Design, Manufacture, Supply, and Construction of Pre-Engineered Steel Building (PEB) for manufacturing of turbines, generators and auxiliaries |

| Location: | Sanand, Ahmedabad, Gujarat |

| Client: | Alstom Bharat Forge Power Ltd. |

| Steel Fabricator: | Kirby Building Systems India Pvt. Ltd. |

Alstom Bharat Forge Power Ltd. (ABFPL), the joint venture company of France's Alstom and Kalyani Group's Bharat Forge, is setting up one of the largest integrated facilities for manufacturing of power equipment - turbines, generators and auxiliaries required for supercritical power plants. This project is first of its type for Kirby Building Systems India which has leveraged its brand name in entering the high potential Indian Power & Power Equipment sector that mostly considers Structural Steel for their building requirements.

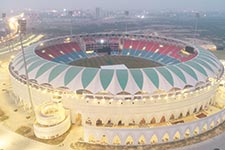

The project involves more than 6,800 MT of steel and is spread over an area of 39,110 sqm. Kirby India was chosen for constructing the factory building after a rigorous evaluation process which spanned across all the departments. The company bagged this project against very stiff competition and was selected among all the PEB vendors based on its expertise in executing a wide range of projects across India. This project further strengthens Kirby India's determination to support the country's infrastructure growth and lays the roadmap for other players in the industry to enter the high potential Power and Power Equipment sector.

Fabrication

The building is covered with double skin Kirby Wall profile and double skin Kirby Standing Seam roofing profile. The roof is further provided with 50 mm thick rockwool insulation to contain the heat and other roofing accessories such as polycarbonate sheet, roof curbs, turbo ventilators, etc.

The entire structure was fabricated in-house with very high efficiency and passing through various processes and systems. Successful execution of the project enabled the company to showcase its engineering, manufacturing, and execution capabilities. All such projects, whether big or small, require not only superior design but also excellent project management. Kirby India is capable of manufacturing such complex structures which consists of very heavy sections that require skilled manpower to follow all the stringent welding and quality standards.