Emerging from their hiding places in concrete columns pre-engineered steel structures (PEBs) are innovative solutions for construction projects across several sectors now as Varsha Trehan discovers.

As Infrastructure construction across the country is combining speed, economy, safety, strength and aesthetics at awe inspiring levels, steel structures, until now a primary foundation element, have risen as complete solutions in construction projects for various structural requirements. India is growing fast as an economy for pre-engineered buildings (PEBs) as it is witnessing a boom in the infrastructure sector. Structural steel buildings or PEBs are addressing parameters including finishes, environment control and life cycle with a panache derived from product innovation and technology advancement.

Emerging as a strong alternative to conventional concrete construction methods, PEB in India is validated by the 33% market share of PEBs in the construction industry. While this figure is lower than some European countries, it marks India's growing global market share at 9.5 percent -- a step ahead of China's 8.5 percent. "The market demand is pegged at 425,000 TPA with a 15% growth per annum," informs the spokesperson from Kirby Building Systems India. "Current market size is around Rs.3,500 Crore and it is expected to grow at 10% to 15% per year," estimates Mr B.V. Rao, Executive Director, Pennar Engineered Building Systems Ltd. Generally, steel structures and specifically PEBs market have, on the domestic front, surpassed the GDP from both the Indian steel industry and the Indian construction sector. Over the next 2-3 years, the industry is optimistic about a 15 to 20% annual growth, resulting in doubling of the market over five years.

Strength building

With the country's five year plan catering for infrastructure addition in the form of airports, metros and bridges sector differentiation is expected to separate industrial buildings and building systems. Companies like Era Buildsys have diversified into verticals within the PEBs segment to meet sophisticated requirements for structure. These include Design & Engineering, Manufacture and Construction & Erection. This pattern of restructuring indicates an industry that sees PEBs coming into its own with experiencing exponential growth with diversification into various sectors and segments.The sector is going international as companies move to tie up with multinationals for upgrading offerings to their customers. "Technical association and JV's with leading PEB companies in Europe, USA and Middle-east are quite useful in terms of engineering excellence, product quality and superior products range. We have technical association with NCI, which is a leading PEB player in USA. By virtue of this association, we are offering a superior standing seam Double Lok 100% leak proof system," informs Mr B.V. Rao.

Major names that have linked up abroad and are significant landmarks of a market that is increasingly sophisticated are Tata BlueScope Steel, Reliance Industries tie up with Mammut Group and JSW Building Systems bonding with Severfield Reeve Structures of UK, as also Phenix Varco Pruden, a JV between Gujarat's MB Group and Varco Pruden Buildings, USA.

It only gets bigger

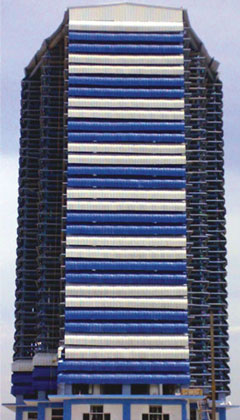

Demonstrating the potential for PEBs are projects like Kirby India's award winning Renault Nissan Automotive India Pvt. Ltd. – an automotive manufacturing facility at Chennai. It is the world's single largest PEB building spread over 300,000 m2 involving more than 20,000 MT of steel. The company also has the distinction of having built the largest ship building facility at Pipavav in Gujarat. Among the innovative structures is recently executed pre-engineered Steel Bridge Girder - first of its type in India for Commonwealth Games 2010 at New Delhi which was awarded by Gammon India. Earlier, Tata BlueScope Building Solutions, a division of Tata BlueScope Steel set a record of sorts with the completion of the ‘East West Gas Pipeline project' of Reliance Gas Transportation Infrastructure Limited (RGTIL). Era Buildsys Ltd has successfully completed multistoried project for Nector Life Sciences in Derabasi, Chandigarh. The building is 45 meters tall, 39 meters in length and 20 meters wide along with louvers and brackets for easy and quick water flow and ventilation.Technical innovations aid flexibility in expansion allows for future expansion in length, width and height. "With large clear spans, buildings can be supplied in clear spans up to 90 meters. This is particularly suitable for structures like aircraft hangars and sports facilities. Standard companies offer superior quality. At Ferro Industries for example, complete manufacturing is done in plant to ISO 9001 quality assurance standards. Additionally, high quality paint system is available for steel and cladding to provide a long maintenance free service life. Also, buildings are supplied with roof and wall insulation to reduce energy cost and improve comfort level inside the buildings," Mr Vishwas Pandey, Business Development Manager, Ferro Industries India enlightens us.

Preferred alternative

Elaborating on developments, the spokesperson of Kirby Building Systems India, said "We have evolved from a mere manufacturer of PEB to a total solution provider for customer needs. The company in the past few years has executed mega projects in the automobile, shipyard, general engineering, infrastructure, logistics, and various other sectors. Kirby India has also successfully ventured into many unexplored territories like power plant structures, bridge girders and shipyard structures."

"Keeping up with the market trend Era Buildsys Ltd has already stretched its arms in various sectors like: power plants, warehouses & industrial building, aircraft hangers, sports stadiums, automobile, electronics, electrical, chemical, cement, FMCG, oil & gas and more," informs Mr Amit Bharana, President, Era Buildsys.

Crossing boundaries

Coming up from roofing solutions as asbestos sheet substitutes, we are now looking at steel structures that efficiently meet requirements of industrial and non-residential buildings. As PEBs are tailor made to meet infrastructural requirements of the client, like supplementing warehouse solutions, PEBs also offer heavy industrial racking. Pre-engineered building is a good solution as optimization of total structural steel weight and time is involved. The low cost involvement in construction makes PEBs suitable for housing, defense and school buildings. Here PEBs have developed capacity to cross limitations of size.Sharing some updates on product innovations Mr Bharana details "The innovative solutions provided by manufacturers of steel frame multistoried buildings are girder slab arrangement, slim floor system which is a space saver solution, steelcrete system on floor to make it very light but stronger than concrete floor, cellular beams for best service integration, composite floor system, site accommodation, site storage and site offices with very light structural steel. Execution time is reduced by 40% over the conventional buildings. The new buildings are designed at grade 70 steel, which further reduces the weight. Since pre-engineered building system is automated with high end design software like Tekla, Autocad, MBS to create a building for a specific use such as power plants, warehouses & industrial building, aircraft hangers, sports stadiums etc, it sets a new trend or innovation in the infrastructure sector."

"Convenience and improvement in design, finish and product range are some of the factors encouraging projects like residential buildings and shopping malls to induct the PEBs solution into the infrastructure" says Mr Sanjay S. Loya, Director, Loya Constructions. "As the designs are finalized through client discussions, the final costs are worked out and mutually agreed upon. That rules out nasty surprises midway construction. With major details worked out, the client is also relieved of day-to-day involvement at construction stage. All these benefits come with a quality assurance for the end product."

Greenfield complaint

Steel, the basic material of PEBs, being very eco-friendly, allows any project high scores on Greenfield compliancy. Design optimization ensures quantity of steel is controlled, and the high tensile strength of the material makes the structure light. Consequently, the foundation is more sustainable. Time saving, clean construction sites, recyclability with low maintenance and extended life cycle of the building are a taken. Further, PEBs allow dismantling, relocating and expansion if the need arises.

Modern insulation and ventilation methods add to the energy conservation effort. PEBs are suitable even in ecologically sensitive areas or geographically remote sites like hilly regions. The scope for integrating other suitable construction materials like glass of course, really wide. Sailing on the trend for getting certified are, among others, manufacturers like Pennar, Kirby India who earned the Gold Rating from the Indian Building Council for its practices. Such manufacturers are building on their strengths to offer comprehensive solutions for LEED compliance for Green Buildings. The motivation to get green practices in packaging and other aspects in a bid to get closer to green building solutions overall is encouraging.

Speed breakers

That India can present extremes in any given scenario, social or economic, is a well known characteristic. In the case of PEBs, this is demonstrated with the presence of massive structures in the manufacturing and public utility areas, the housing sector considers PEBs mostly for temporary sheds and cabins. There is a gradual inclusion of this technology as quake resistant building code compliances are being enforced, especially for highrise structures. Shopping malls and group housing show benefits from PEBs product design and applications.The shortage of trained or skilled workforce at the construction stage is often a stumbling block to achieve delivery targets and finish quality. Companies vying to maintain standards are forced to develop their own teams, especially at the supervisory levels to ensure customer satisfaction.

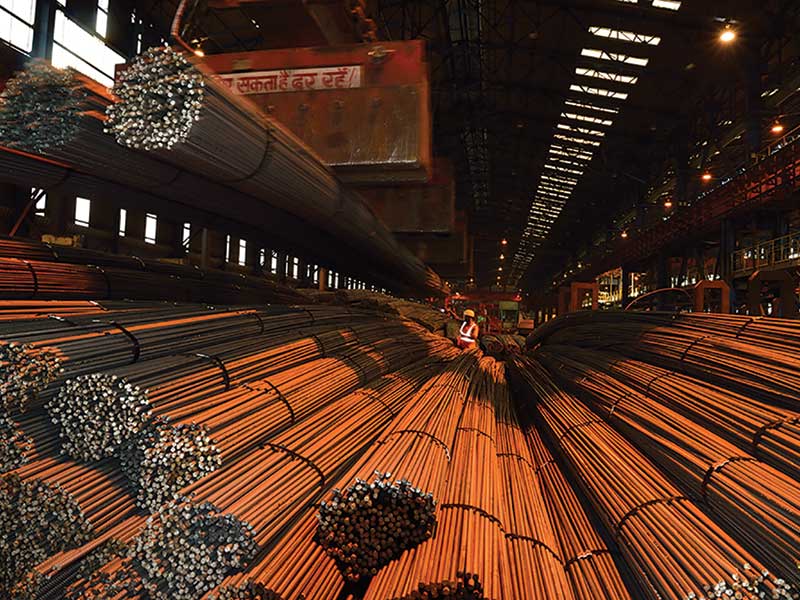

"Acquisition of steel, the primary raw material, often causes concern due to the rising costs and discrepancy of taxes," rues Mr Sanjay Loya. "Raw material costs are in upward trend due to shortage of coal and iron ore. Government of India needs to consider reducing the tax burden on these pre-engineered buildings in order to promote this industry which has significant role in scaling up the infrastructure and also generate employment opportunities" says Mr P.V. Rao agreeing on the issue.

Codes: All for one

In an unorganized sector, the lack of standards and codes leaves the customer in a quandary. Presently, unethical manufactures conveniently tend to mix and match codes for individual building areas, raising doubts about the integrity of design and the overall product. In developed country like USA, the engineers enjoy AISC/MBMA recommendations for PEB applications, whereas in India, PEB specific code is yet to be formulated.

As Kirby India tells us, "All the buildings are designed according to AISC or IS or MBMA codes as per the customers' or consultants' requirements and are strictly in line with the standards followed in developed nations. They have to be designed as per the project site since each location have different conditions such as wind speed, seismic zone category, weather conditions, etc. These changes the building tonnage as load conditions are taken into consideration according to the project site and applied at the time of design stage to maintain the stability and sustain all the natural happenings. All the leading PEB players are planning to come out with standard design code for the industry in near future. Even the Institute for Steel Development & Growth (INSDAG), an institute under Government of India, is coming out with manuals on steel buildings, which will further promote the usage of these in India." Mr Bharana opines "We do not have a specific Indian standard dedicated to PEB application to Cover knowledge of advanced steel design while using HSLA steel. The latest IS 800 – 2007 covers steel design by Limit State Method, but still restricted to use concepts for conventional steel design. It is yet to cover the broader spectrum of PEB application. Major players are applying these principles, but within the domain of present the IS: 800 – 2007 code. Too often this faces resistance/criticism from Consultants with conventional steel design background. Web tapered members, thin plate webs, and single side welding at flange to web junction - are still a nightmare for most of the Indian Steel design Consultants."

Bringing together the best of international experience and modifying to suit Indian conditions is not far and that, in a market heading for exponential growth, is relevant.