"PEBs have a great future in India as they offer numerous benefits. Design of used structures is vetted by structural consultants to withstand load, resist wind and earthquake. With minimum maintenance, their lifespan can extend to more than 40 years. In the Hospitality industry PEBs have given very good payback. They are also the most suitable for meeting the immediate requirements in Education and Health Centers," says Hiren Shah.

Material Palette

Basic ISI marked Structural Steel: Rectangular Pipe-50x50, 50x25,100x100,etc

Wall: Cement Fibre (Ecopro/Visaka)

Inside wall: Cement Fibre Board, 8mm thick

Outside wall: Wood Textured Planks, 8mm thick

Roofing: 50mm PUF Insulated Panel

Pre-painted Galvanised Sheet - Jindal

Doors: ISI marked Flush Doors

Both side laminates: Greenlam

Locks: Godrej

Window/Vents: Powder Coated Aluminium section

Floor Tiles : 2'X 2' Matt Finish Vitrified Tiles

Wall: Glazed tiles

Switches & Sockets: Anchor

ACP Sheet (Inside): Timex

Platform/Counter: 18 mm thick Granite on Kotastone

Paint (inside) Plastic/Oil Paint - Asian Paints

Paint (outside): Apex - Asian Paints

Steel Structures: Oil Paint - Asian Paints

"For Housing Rehabilitation programs following calamities such as earthquakes, floods, etc, they can be used to create permanent or temporary housing shelters; for building an additional floor in old buildings as they are lightweight; an office in a factory shed without disturbing the factory's ongoing operations," he adds.

According to him, as a green product, PEB structures have great potential where construction activity is restricted as in forests, hilly areas and sea shores. They need minimum electricity and water and other natural resources for construction. Since vehicular movement in restricted areas is approximately 10% of the conventional structures, there is minimum disturbance to nature.

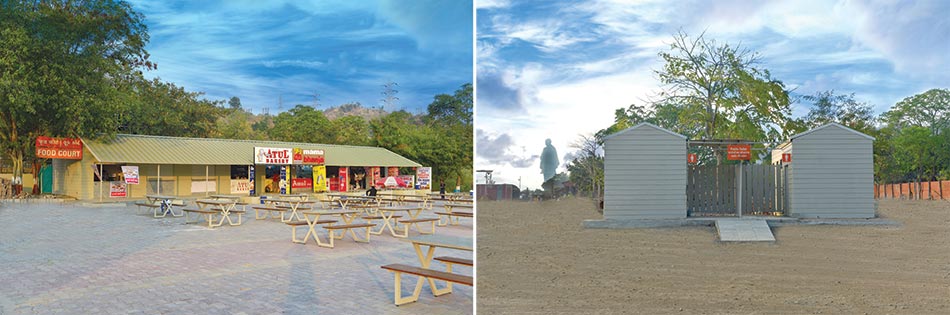

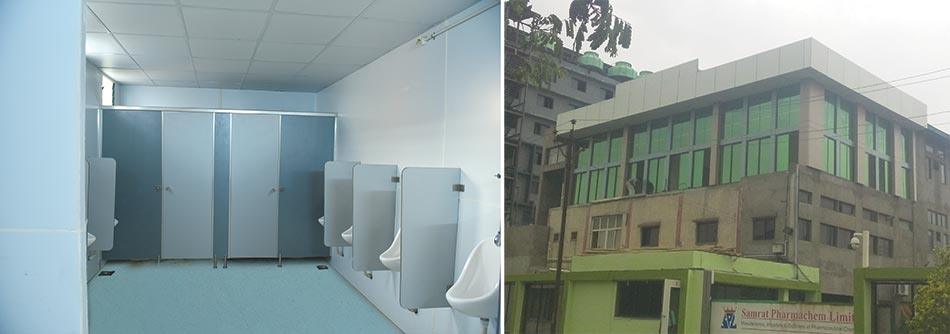

For the Statue of Unity Project, the company undertook building the following PEB structures as per the project requirements.

- Food Court with nine shops: Covered Area - 3800 sq.ft. Time frame: 15 days.

- Souvenir Shop: Covered Area - 200 sq.ft. Time frame: 5 days.

- Viewing Gallery: Covered Area - 1300 sq.ft. Time frame: 10 days.

- Toilet Block: Covered Area - 550 sq.ft. Time frame: 5 days.

- Detailed Engineering

- Supply of Prefab Structures, Cement Fiber Boards, Roofing Material, Doors, Windows, Wall and floor Tiles, Paint etc

- Installation at Site and Painting work.

Features

- Excellent aesthetics

- Strong, yet lightweight

- Quick and easy to install

- Pre-tested components

- Economic and durable

- Good Insulation hence energy-efficient

- Lifespan of more than 40 years with minimum maintenance

- Fire, Earthquake and Termite Resistant

- Majority of components can be relocated

- Due to thinner walls more carpet area.