Anyone pondering about the suitability of a precast concrete structure may be unsure on how to truly evaluate its benefits. Concept design services will help in adopting the right precast concrete technology by providing a clear cost calculation and a plan for the most suitable products and materials

Prakash Shah

It all starts with an evaluation: a good concept design includes a thorough evaluation on how current and future projects could be structured using precast, and whether to use complete or composite structures. The performance of the precast building in the local ground conditions and the required precast product types are also evaluated.

A good example of concept design is the one used by Jindal Reality (JRPL), who used Elematic’s precast technology in their Jindal Global City and University project in India. Jindal was looking for a construction technique that would entail rapid construction, high quality, and less labor-oriented work.

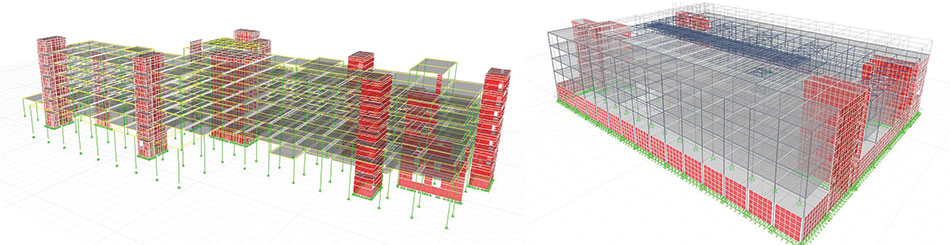

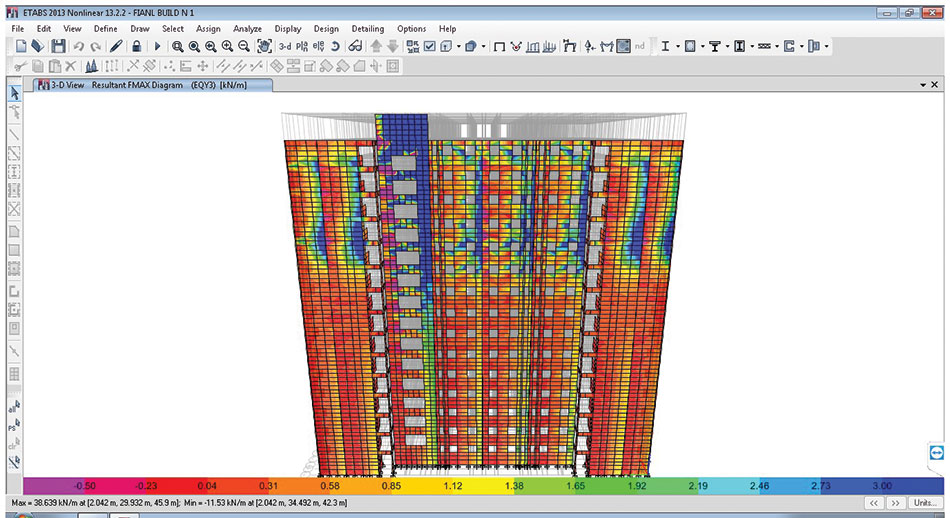

We carried out concept design for their building requirements; provided details on how precast can be implemented and on the construction methodology. Based on our inputs, JRPL successfully finished the construction project of several 6 to 9 storey tall buildings of approx.10,00,000 m² in a high seismic zone-4. These buildings are completely precast structures comprising the wall-frame system, which gives better utilization of the floor area as compared to conventional construction.

Importance of a concept design office

When taking up a new construction method, it’s extremely important to find a professional partner who can help you in reaching the best possible outcome. In fact, when considering which structural engineering services provider to choose in the pre-casting field, special attention should be paid to several factors besides the critical concept evaluation.

The design engineers should have a sound know-how on developments in the precast industry, along with good practices of successfully implemented systems. In addition, they should have experience on geographically varied projects, international structural standards and utilization of varied programs. They should have a sound knowledge about precast production, plant operations and efficient working methods, as well as structural connections, as the lifetime behavior of precast buildings is one of the most crucial aspects.

Preparing for concept design project

Understanding the nature of the project in totality is crucial for the concept design team, because it’s the starting point for evaluating the suitability of precast to the project. For the best possible outcome, the team needs to receive architectural drawings, including layouts, elevations, sections and special features, if any. In addition, details of building utility services arrangements, local seismic details and costs of local structural materials are needed.

The concept design phase usually takes 8 to 10 weeks to complete. However, all projects are unique in terms of architectural complexity, seismicity, geographical location and other construction requirements; hence, a precise time for the designing phase cannot be provided before knowing all the details affecting the design.

Concept design report crucial

The end result of a concept design project is a report that should include all necessary information such as basis of structural analysis and design, including loading data, design code details and structural framing concept details with precast arrangement, and typical connection details of various precast elements.

The report should also entail sizing, geometrical details and a number of different precast product types, including reinforcement, prestressing and concrete strengths, and any suggested changes to architectural design, to make the building more efficient. Finally, it should have details of production set-up and equipment requirements.

One of Elematic’s customers in concept design is KEF Infrastructure, which constructed the PMHS Hospital in which city?? - one of their first precast projects in India. KEF was already exploring precast technology for the project but the suggestion they had at that time was rather old-fashioned and labor intensive, with complex production and execution. If the original plan had been followed, the project would have been costly and time-consuming with questionable results.

We carried out concept design for the hospital building, giving details on how modern precast concrete technology can be implemented with efficient precast element requirements. We also gave advice on how to set up a productive and very flexible production system, which will cater to the various project needs in the future.

As a result, KEF was able to set up a productive and cost-efficient solution for the challenging hospital project comprising 300,000 m² area, located in seismic zone-3. The structural system comprised multi-storey reinforced precast columns, prestressed precast beams, hollow-core slabs with structural topping, staircases and special- featured graphic concrete façade panels.

Total solutions

After in-depth knowledge about the precast construction technology and its suitability to the client’s project, the next step is to discuss more about the structural system, suggested architectural changes, project costs and precast production set-up requirements. Besides a feasibility study, Elematic can help in finalizing the building details and setting up a precast plant, for which the company provides solutions from design to its complete lifecycle.