Aesthetics. . .

Moreover, not only outside, but also inside today's modern buildings is also extravagant, with stairs, projections, plants and lighting to consider. As well as glass and facade cleaning, there are more jobs to do at height. The building manager is therefore absolutely interested in making sure the structure is most in good condition with as little trouble as possible when doing the necessary work. On the other hand, the safety of the responsible people is very important. This means they must be able to solve these problems of working at height by being given the right tools. This is where aerial access platforms come in.. . .and focus on profitability

In order to work safely at height, only access platforms can be used. "This is where our rubber-crawler-mounted LEO series is particularly strong" explains Hermann Leusder, technical manager of Teupen Maschinenbau GmbH, Gronau, Germany. "No situation is too complex, no space too small, nor floor too sensitive for our machine technology. Inside as well as outside this series shows its strength."

Safe design of equipment

Architecture has changed dramatically in the last few years. This greatly affects the interiors of prestige buildings, which present themselves extremely extravagantly to the public. When working with access platforms, it must be fundamentally guaranteed that on one hand the building is cared for and on the other the operator is completely safe. The operator has his safety in his own hands in as much as he should wear a safety helmet and safety harness, plus any other required by regulations. The standard of the machine is constructed by the manufacturer.There are many different types of aerial platforms, amongst others, scissor lifts, trailer-mounted, truck-mounted, self-propelled and rubber-crawler-mounted. The latter available from 12-50 m and can be used indoors. Worldwide there are approximately ten manufacturers of rubber-crawler-mounted machines. In sorting the wheat from, however, from the chaff, it must be determined what technology the machine includes, as to what the machine can do; easy to operate? What about weight on sensitive floors? Spare parts available? After-Sales-Service and so on? "Further, national CE marks and international EN 280 norms have to be taken into account in building such machines" Hermann Leusder made clear. The "solution expert" for complicated applications at height, Teupen Maschinenbau builds machines to all current national and international standards.

Various choice criteria

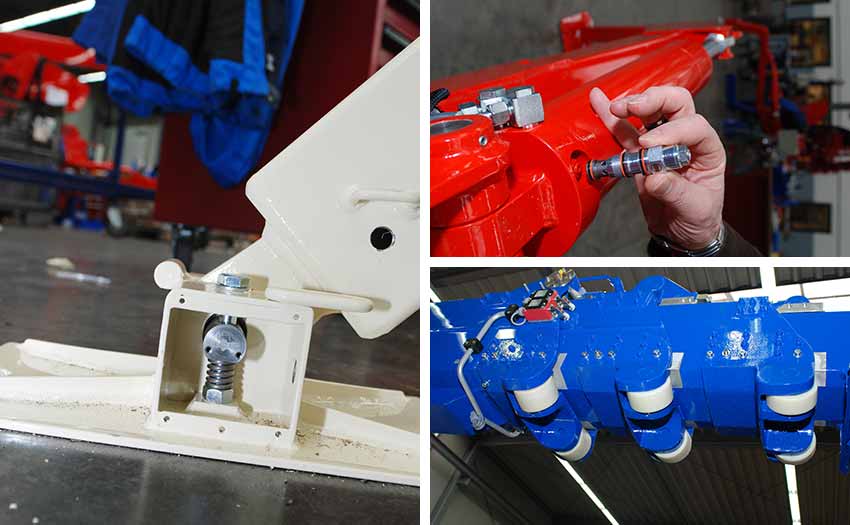

"High working height, light, a big outreach, as well as a dynamic, problem free telescoping out. That is what the ideal new generation access platforms looks like. In order to cover all these points", the technical manager said, "many construction criteria had to be taken into account." The total weight of the machine plays an important role. The lighter the machine is in the telescoping boom and the basket, the higher the boom can telescope out, therefore giving a longer outreach and a more manoeuvrable basket. Teupen is able to achieve this by using very light metals, either reinforced aluminium, or special aluminium alloys, such as are used in the aircraft industry, for example. In this way a lot of weight is saved, but a higher level of safety achieved.The technical manager reported that the special alloy used by Teupen is called Aluminium Foam Sandwich (A.F.S.). The metal is formed by pressing a specially foamed granulate between two pressed aluminium plates. This aluminium sandwich concept gives a light, stiff structure, but which is very strong and safe.

An access platform built of steel with a wheeled chassis is a big, heavy machine, which takes up a lot space and creates enormous ground pressure. In order to avoid damage, the weight of the light crawler-mounted machine made of aluminium and steel is distributed over the greater area of the crawler on the ground/floor, than wheels. This enables all sensitive ground/floors, such as marble, carpet tiles, sewage pipes, lawns and so on to be negotiated without any problem due to the much lower point loadings.

Source of failure: human error

At the actual work site the sophisticated Teupen control technology plays an important role. The now standard and for access platforms developed "Fuzzy Logic" on only Teupen machines, works smoothly and reliably in operating these models safely in all conditions. In addition, this modern generation of access platforms including articulated booms enable the operator to reach every corner and up and over overhangs. Indeed, the more flexible is the boom, the better one can reach one's workface at height. A further safety aspect is that the telescoping sections operate via a roller system, enabling a self-centralising both out and in of the boom for safety, sureness and smoothness.

The operator's basket must also be considered from a safety aspect. The basket and jib operate like a human hand and wrist for greater flexibility in order to reach every nook and cranny and this must be achieved without any dangerous contortions. The operator can concentrate on his work and feel safe and secure. Basically, the more of the above-mentioned safety features there are on an access platform the more unlikely it is to be able to damage during operation. It is human nature to ignore danger in attempting to attain one's goal. Thus, conversely, the more impossible it is to cause problems during operation because of the increased technology, safety features, safety increases.