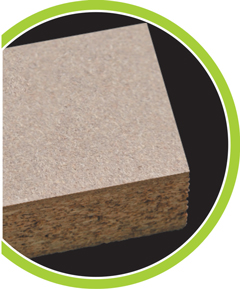

Why is choosing the correct Particle board important in determining the quality of your furniture?

Particle board is an engineered product capable to last a decade withstanding the daily use/abuse just like plywood if used of the right quality with the right Modulus of Rupture, Modulus of Elasticity and Internal bond properties. HeveaBoard specialized in producing Low Emission Particle boards which do not compromise on mechanical properties.

Why do door hinges loosen after some time?

Holding hinges is a property of the construction of the board. If the board has a low internal bond the hinges loosen within short time and can cause the shutter to come loose from the carcass.

Why do cabinet shelves start to warp after some time?

Sagging or warping by placement of any weight on the shelves is caused by the board having poor modulus of rupture. A poorly produced board can sag even by its own weight!!!

Why does my furniture made of particle board swell?

Swelling is a natural reaction to moisture for any wooden product however the resin formulations inhibit swelling to a large extent to less than 8% after 2 hours immersion. However compromise on the resin additives and formulations will cause reflection on furniture by display of the swelling.

Why are Bending Strength and Internal Bond of Particle board important?

Bending strength and Internal Bond are the key engineered lifestyle properties of the particle board which reflects like a healthy heart and a positive mindset in a human body. Poor properties mean premature death of the furniture.

HeveaBoard

Hevea Board Quality vs Competitors.

eg. Bending strength of >13N/mm2 vs 10N/mm2.Internal Bond of >0.35N vs 0.25N.

Thickness Swelling <5% vs <8%

HEVEABOARD never compromises on quality and ensures the product at market prices at all times. It has dedication to uplift the falling standard of quality in the particle board industry. All boards look same from outside to a furniture manufacturer and lack of the knowledge of cause and effects of the key properties on the life of furniture is rapidly earning a bad name for particle board industry in India.

What is Formaldehyde?

Formaldehyde is a common precursor to more complex compounds and materials. When treated with phenol, urea, or melamine, formaldehyde produces, respectively, hard thermoset phenol formaldehyde resin, urea formaldehyde resin, and melamine resin. These polymers are common permanent adhesives used in plywood, ParticleBoards and MDF. Production of formaldehyde resins accounts for more than half of formaldehyde consumption.

Why is Formaldehye hazardous to health?

Formaldehyde has been declared a known carcinogen chemical and for any indoor use the emission level is necessary to be below 8mg /100g oven dry board.

Why choose low emission Particle board?

Low emission ensures the air quality has no toxic emissions from the furniture items. In India unfortunately the awareness of the formaldehyde emissions is too low. In EU all engineered board manufacturers have self imposed to produce only E1 norm as standard minimal emission and other countries too have similar or lower emission like E0 level board mandatory. HeveaBoard can supply upon request E0 as well as CARB P2 and F**** compliant particle boards.