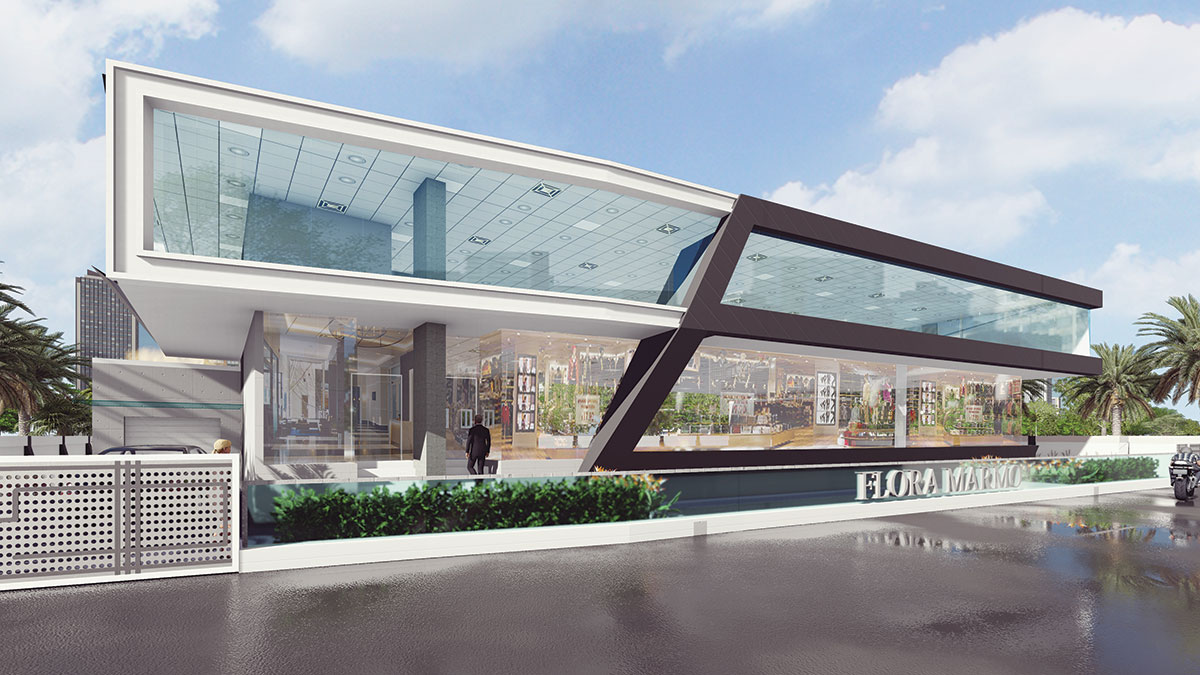

Project: Flora Marble Showroom

Facade Design: Ar. Reza Kabul

Implementation of Solid Surface: Ar. Harish Gupta, Habitat n Skins

From the robust stone face on buildings that project the strength and secure nature of the organizations that inhabited them, to the glass fronts which essentially promote transparency and the approachable attitude of the corporate world, architecture is now shifting towards flexibility as we see building design becoming more curvilinear, and more tuned to the idea of futuristic development on the lines of dynamic fluidity.

Dynamic fluid lines in architecture needs new materials that can be shaped in 3-D to take on any design challenge. Currently, there are six or more materials predominant that can meet the challenges of modern dynamic facade design, namely:

- Metal sheets cladding

- GFRG or glass fiber reinforced concrete

- Resin bonded fiber glass

- Tensile fabrics

- Solid surface

- Glass

Curvilinear design using Solid Surface at the Netherlands villa. Pic courtacy: Corean

Curvilinear design using Solid Surface at the Netherlands villa. Pic courtacy: CoreanSolid surface is the new wonder material in the façade industry, though it has been in the market as a table or kitchen top material for many decades. First introduced by DuPont 50 years ago under the brand name Corean (now a generic name for this material), solid surface is now offered by many companies across the globe, but each company’s product is a little different and must be selected after understanding its merits and demerits. Solid Surface is being offered by the following companies:

- Formica Group Solid Surfacing

- Du Pont

- Hanwha Hanex

- Velstone

- Krion Porcelanosa Solid Surface

- LG HI-MACS

- LOTTE Staron (Samsung Staron)

- Rehau

Fluid architecture in Solid Surface: Pic courtesy Krion

Fluid architecture in Solid Surface: Pic courtesy KrionFeatures

The primary composition of the Solid Surface is 65-70% of alumina trihrdrate, which forms the basic mineral content, with acrylic, epoxy or resin and color pigments as the other components, though there may some differences in the composition by the solid surface producing companies.

Solid surface can mimic high gloss or matt solid colors as well as granite and marble-look variants. Only the 65-70% mineral content is non-combustible and gives a fair resistance to fire with addition of fire retarder additives.

The other components are acrylic, epoxy or resins, but the fire resistance properties differ from company to company and therefore need a closer look when specifying for projects. The material has low flame and smoke spread when subjected to fire, and softens at around 180°C, which is its molding temperature to achieve various shapes. This must be kept in mind when the material is being used extensively in façades because when it softens it will sag and may lose its integrity.

Solid surface’s joint free and monolithic features give complete freedom to create large designs fashioned from a single element. As an eco-friendly material, it enhances sustainability and occupier well-being. Its UV stable colors seal the external beauty for years and make it low maintenance as well.

Reza Kabul, Principal Architect, ARK

Flora Marmo Showroom

For the Flora marble company located on the Western Express Highway in Mumbai (Pic 1), Ar. Reza Kabul has specified the UV-resistant solid surface for the exterior cladding.

Pic 1: The cladding sheets of 12mm thickness are in two colors and mounted on an aluminum grid sub frame with undercut anchors to hold the sheet from behind (as shown in the diagram below right).

Pic 1: The cladding sheets of 12mm thickness are in two colors and mounted on an aluminum grid sub frame with undercut anchors to hold the sheet from behind (as shown in the diagram below right).The smooth and glossy seamless finish highlights the continuous glass façade designed by the architect. The implementation of the solid surface will be a factory-controlled production process, and will be done under the umbrella of Habitat n Skins - the principal design built façade installers for the project. The material supplier’s trained team will undertake the cutting and joining with a special glue that bonds the material to give a seamless surface. The joints of each panel are sanded and buffed such that they become invisible, even to a trained eye.

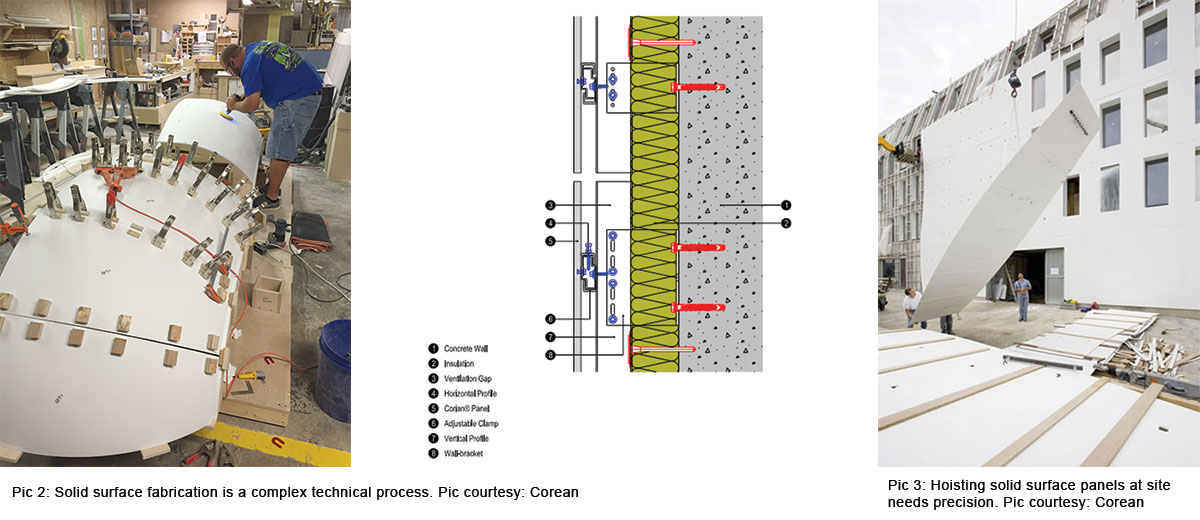

Pic 2 shows the production of the individual panels is a complex technical process. The panels will be transported from the factory to the site after being finished to high accuracy, and attached to the prefixed aluminum grid. The cladding is weather resistant with all the components having high resistance to any type of weather conditions. However, the cladding does not prevent water ingress and needs an impervious sub-structure as shown in the fixing details (Pic 3). The picture shows how panels are lifted and placed on the aluminum sub frames to finish the building façade.

Solid surface is a better material in terms of fire resistance as compared to PE or LDP core ACP cladding, which have high flammability

harishgupta@habitat-n-skins-com

The final outcome is a continuous surface with virtually invisible joints making the design scale-less and replicating a factory finished building structure.