Harish: The T2 elevation with GFRC (glass fiber reinforced concrete) has been the highlight of the new terminal. The sheer size and scale of the beautiful elevation and the detailed intricate design like poetry in the solid white facade catches the attention of every visitor. How was the initial design concept conceived?

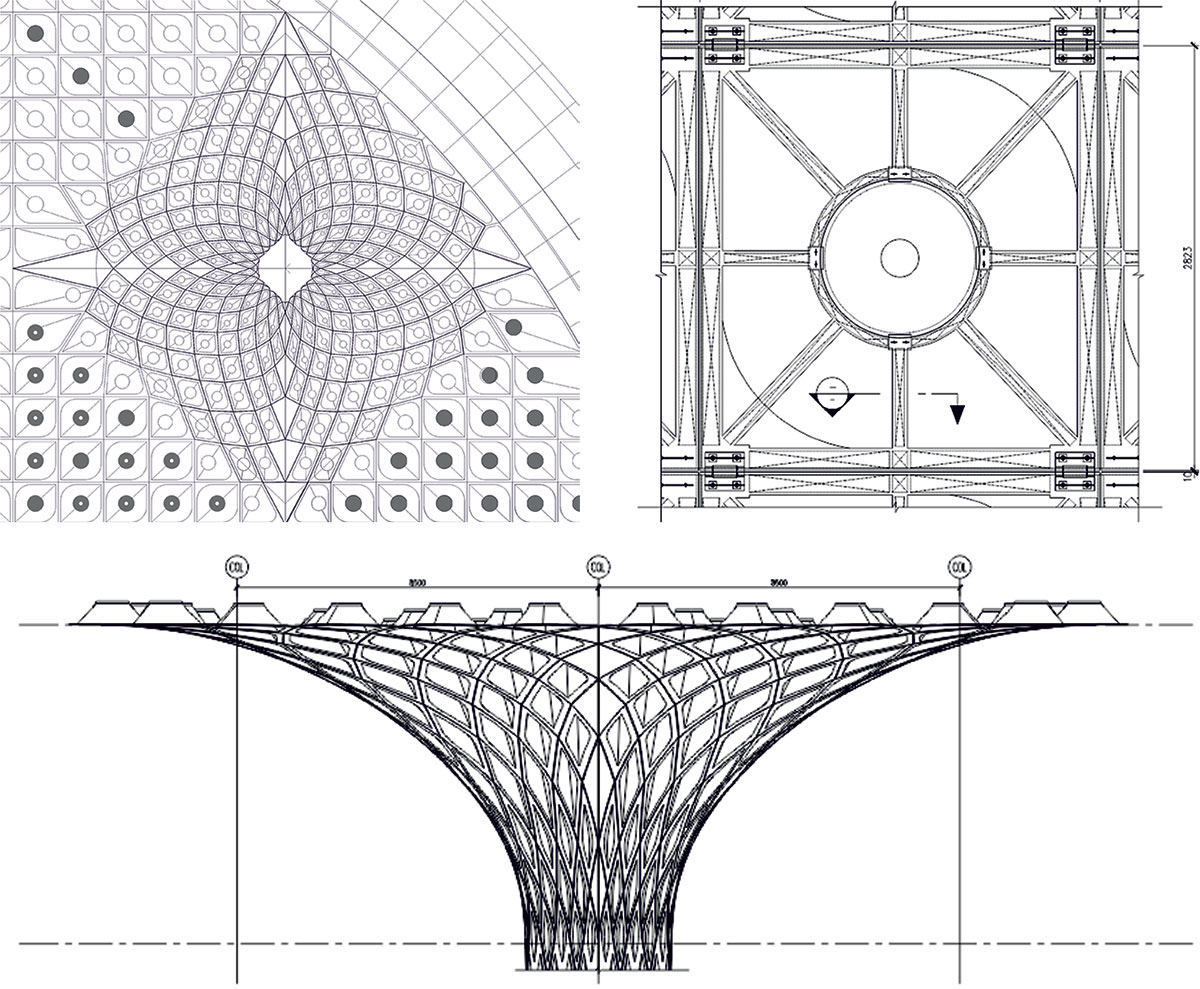

Chintan: The brief for the T2 terminal given by GVK to the New York-based designers SOM was the most beautiful mascot of our country - the peacock. SOM based the design around peacock feathers and the inspiration for the column design, which flowed from the vertical and spread to the horizontal ceiling pattern represented the way the feathers create the pattern. The designs were made abstract to ensure that they were not very obvious, yet identifiable to the eyes of a keen appreciator of architecture.

The application of GFRC and GFRG have perhaps not seen such a huge application in a single project anywhere else in the world and is one of the features why the T2 terminal has been awarded the “best airport in the world”. In fact, there are many other unique features in T2 which are not found in other airports

Ar. Chintan Shukla, Vice President – Project Planning and Design, Navi Mumbai International Airport

Harish: Why did u choose GFRC as the material for the columns and the ceiling? Surely there would have been other choices?

Chintan: The exterior façade and ceiling is made of GFRC and the interior columns and ceiling are made of GFRG which is glass fiber reinforced gypsum. Both GFRC and GFRG were the only materials that could give us a 3 D geometry with the flow of curves. The entire construction was not possible on site and the two materials, though different in nature, were the clear choice to be fabricated off site. We contemplated use of resin bonded fiber glass, but it did not come out as the ideal material for this project.

When two architects meet, architecture becomes the topic of discussion! Chintan was my colleague at Pheroze Kudianavala Architects in the 90’s. His pet project, the T2 terminal at Mumbai – with its wondrous elevation element, never fails to awe me every time I visit the airport. The exterior façade and ceiling made of GFRC and the interior columns and ceiling made of GFRG, the sheer size and scale, and the intricate design, are the beautiful highlights.

Ar. Harish Gupta, Habitat-n-Skins

Harish: My experience with GFRC is that there are many companies in India who do such works but I doubt if any of them could have handled this kind of scale and complex geometry. . .

Chintan: Yes, you are right. We gave the works to two different companies. The external GFRC was given to a company from Hong Kong/China and the internal GFRG was given to a company from Canada. Both the companies had the professional team and production capacity to produce the 3D geometry and make the moulds to a highly strict tolerance. The geometry was finalized for all the columns and ceiling and each piece was constructed in 3D model, which was transferred to the mould design team only after the modules were cleared by the structural consultant, who had to ensure each piece could withstand its own weight and other stresses that the design would undergo during its very long life.

Of particular interest were the groove lines of the GFRG ceiling inside the check-in terminal and the GFRC ceiling outside the terminal, which were separated by a glass wall, and both the ceiling groove lines had to meet perfectly to ensure the desired aesthetics. Since both the ceilings were being manufactured at two opposite ends of the globe, it was important that only the best in the world were chosen for the works.

Harish: The GFRC columns, which are divided in many modules, look very heavy. Handling them and fixing them in position must have been quite a challenge?

Chintan: The modules were quite heavy ranging from 500 kg to a 1000 kg each from column to ceiling. The modules had internal galvanized steel reinforcement connected to insert metal clamps; these had to be positioned most accurately with the internal steel frame that made up the cage around the RCC columns and the roof structure. The alignment was not simple, and every module had to be adjusted exactly as per the 3D model, otherwise, the next module would not fit in, and that was a huge installation challenge. The highlight of the job was that the installation teams had to rely on the accuracy of the production companies from the different countries, making it a mega scale complex installation. Every module installed was checked with laser equipment to ensure that nothing went wrong.

Harish: This sounds like a huge challenge! Considering the width of the head honse that is spread across 350 m, to maintain such accuracy to make the modules rise from the floor and meet accurately in a crisscross ceiling grid, makes the mind boggle. What were the other features of the ceiling modules?

Chintan: The ceiling modules had to be coordinated perfectly with the services layout above it, and the skylight at every column at roof level that filters natural sunlight through the circular lenses in the ceiling modules. The roof and ceiling are separated by a service floor that has the main MS frame structure that holds the terminal roof structure and acts as a maintenance space for all the services. The highlight of the ceiling is the circular DICHROIC glass in each GFRC and GFRG module and the huge skylight at the roof level which filters the sunlight in a spectrum of various colors similar to that of a peacock feather. The circular lenses represent the multicolor circular spots in the peacock feather and can be seen in daylight when the color changes as per our direction of sight. On a bright sunny day the true marvel of the design can be experienced to the fullest.