Picture Courtesy: Artius

The Fenestration Industry is abuzz with wider and more varied product offerings as companies enhance their portfolio with a variety of window styles, shapes, and sizes. Window frames are also breaking away from the conventional whites, browns and greys to offer blues, reds and greens and uncommon finishes to match the interiors and the facade.

With the budgetary boost given to the real estate sector, the construction industry is set to witness a resurgence in demand. This bodes well for the Fenestration Industry as doors, windows and curtain walling systems are integral to the development of modern structures. With major international companies having set-up base in India, builders and architects are looking for the latest technologies and end-to-end solutions to meet the modern fenestration requirements of their projects, where sustainability is also a key focus. They are looking for companies and fabricators that offer a diverse and innovative product range using energy-efficient and environment-friendly materials, and which have a proven track record in providing the right solutions to mid and large scale projects, with the capability to customize the products, along with structurally sound installation. While wood, aluminium and uPVC are the most talked about fenestration materials today, steel, fiberglass and composites are also seeing a growing interest. Discussing the trends in the Indian Fenestration industry, Architects Vikas Gandhi, Babika Goel, and Harish Gupta share their first hand experiences with various materials and their pros and cons with MGS Architecture.

Picture Courtesy: Agostini

Architect Vikas Gandhi

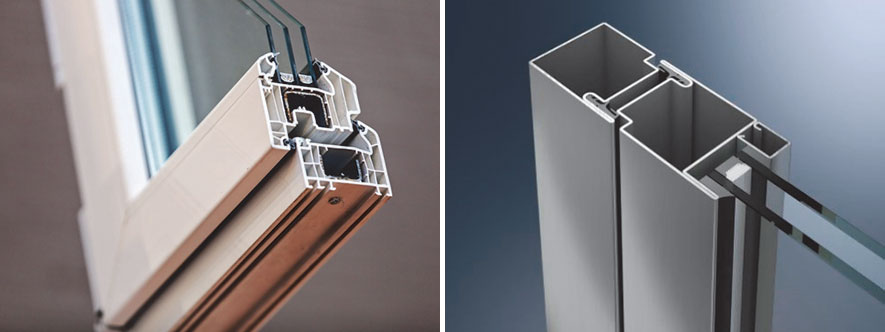

MS window quality and sections have also improved but use is restricted. Can be done in SS as well. Stone frames have also been used over the years in certain parts of India. However, one has to consider factors such as performance, durability, heat and sound insulation and safety, all of which are most critical. For exteriors, aluminium has proven to be the most durable. The profile design of aluminium has also ensured good sound and heat insulation. Even uPVC profile has a good profile design but it is certainly not as strong as aluminium in terms of durability. Aluminium sections can stretch itself for large sizes compared to uPVC. Large windows can be created in wood as well but one has to consider well seasoned good quality wood so it doesn't bend. It is more feasible to make larger windows in sliding details than casement. Wood and uPVC are restricted in colours. Aluminium has various shades and comes in both anodized and powder coated. There are some wooden finishes as well in these materials though I do not advocate copying the looks of another material.

Fenestrations are essentially the interface between the outdoor and indoors. There function is to let in light and ventilation. They also expand our view from the inside to the outside and act as a connection. While designing fenestration one has to balance the spatial needs to the climatic needs and needless to say they certainly are part of how the façade looks. In our experience, we have found wood and aluminium to be more versatile and durable than UPVC. A combination of these can also be used within the same project. Aluminium creates a perfect outer window as it is least affected by the elements. On the other hand, wood has a very nice, rich and warm feel and is truly preferred indoors. To make the fenestrations more contextual, one must also see it in continuation of the design theme, thereby accentuating the architecture language.

Architect Babika Goel

The market today is offering windows in uPVC, aluminium, steel, engineered wood, Aluwood combination, and fibre glass. Fibex, introduced by the Italian Agostini Group, is a frame made of glass fibre for maximum strength and insulation with a combination of external and internal cladding options of glass/wood/bronze/stone.

New surface finishes being launched in the past decade such as aluminium profiles with multi-dimensional wood coating, cladding such as stone, metal, wood, or leather to match the interiors, are much in demand for their aesthetic appeal. Agostini Group is coming up with a series of shutters and blinds in aluminium and aluminium-wood with insulating fibex inserts that ensure incomparable thermal insulation, and special designs which give limited ventilation without compromising on security. Indian company Artius is offering (Canadian) wood systems with features designed to suit the Indian climate.

Picture Courtesy: Artius

A country like India needs window systems which are dust proof, thermally insulated, secure and sound proof (where required). Interlocking seals between sashes that make sliding windows completely sealed and secure, trackless systems with a cavity at the bottom so that dust does not collect and the windows are easy to clean (for instance Artius engineered wood systems), and outward opening windows where the sash can be moved for an easy to clean position, are some options.

Larger size windows will require huge glass sizes, so it is important to consult glass manufacturers for double glass units that take into account wind load, security, structural strength, acoustics, thermal insulation, etc. Glass compositions with thickness varying from 37mm to as high as 50mm are being used in German company Schuco's aluminium windows systems that ensure and guarantee the required assembly.

Imported window systems from Europe are meeting the need for professionalism, innovation and quality in premium residential, commercial and hospitality projects in India. These companies are able to take up projects to offer exclusive and innovative solutions that adapt to the uniqueness of Indian climate conditions so that the "closure" actually becomes an integral part of the building. This means creating a project that is not limited to standard doors, windows and shutters, but one that enhances the architecture and environment for which it is destined.

Ar. Harish Gupta

Wood and UPVC, UPVC and Aluminum, wood and aluminum

The choice of materials also depends of what is suitable for the scale or price. For very large sizes and for a very sleek look, aluminum is by far the clear choice like in the panorama windows from Keller, Schueco and Vitrocsa.

Architects the world over like to work with minimalistic systems and love to see only the glass to bring in the exterior view as much as possible. Here, aluminum with steel reinforcement combined with rigidity of double or triple glazing, offers some of the most stunning seamless combination views.

Keller Panoroma aluminum windows

|

|

| Schueco Panoroma aluminium windows | Vitrocsa Panoroma aluminum windows |

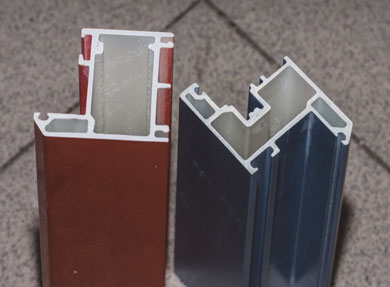

uPVC is cost effective and homogenous like wood and so camouflages any scratch beautifully, compared to aluminum which has a coating only on the surface. On mass housing projects and areas with moderate temperatures uPVC offers a better solution compared to aluminum and is a better insulator of heat. However, it scores poor on large size and broken glass replacement parameters as the joints are mostly fused at the corners rendering the window virtually useless many a times.

New materials that are making news are steel/stainless steel and fiberglass. Cold rolled stainless steel sections are very sleek and strong and can offer a wonderful finish. The fire resistance of steel surpasses any other material in the market and will one day be the material most sought, provided cost is not a concern.

|

|

| uPVC sealed window | Cold rolled steel windows section detail |

Fiberglass is seen as a future replacement to uPVC windows. Fiberglass windows have more color choices and customizable features than uPVC, and more strength (some fiberglass windows can be up to 5 to 7 times stronger). It is composed of glass fibers and resins (or silica sand) which are better able to expand and contract as the weather changes allowing it to maintain its integrity. Moreover, since silica sand is an abundant resource, it takes much less energy to manufacture fiberglass windows than it does to make of uPVC.

Stainless steel sleek window systems

Fiberglass painted profile

Composites windows combine the best features of every material and can offer some of the most sophisticated solutions, for example, wood and uPVC window with thermal break or wood and aluminum window with thermal break. Thermal breaks are ideal where the temperature variations go to extremes and are the ideal solution for energy savings when combined with high performance double or triple glazing. This reduces the heat gain or loss to levels unachievable by any other window system. Though the cost is high, this type of window eventually pays for itself over the years in energy savings.

Wood and UPVC window with thermal break

Fenestration is an experience by itself. The sheer joy of opening a large panorama window as in one of the 65 story buildings I have overseen is incomparable to any window system in modern high-rise and comparable only to very premium windows of expensive villas. The windows in question were from a reputed German brand and required extremely high precision. Working with large sliding windows of sizes like 10m x 3.3 m can be a very challenging task where precision levels are 0-2 mm. The aesthetic appeal of these windows is such that whether open or shut, they offer a seamless view and continuity to living spaces. The challenge of such large windows is the logistics from factory to site and placing them with great precision and care. These windows need special handling and a very experienced project manager and a façade specialist to understand the finer points as any mistake can be very costly.

Vitrocsa Panorama turnable aluminum windows