Aluminium - the third most abundant element in the earth's crust finds its implementation in many sectors due to its environment and user -friendly nature - in Building and Construction (B&C), power sector, automotive, packaging, household appliances etc. The surge in the demand of this youngest metal of the non-ferrous metal industry is indicated to the escalating infrastructural development of the country. According to a recent issue of the European Journal of Business and Management, published by International Institute for Science, Technology and Education, the overall consumption of aluminium in India is projected to be about 5 million tonnes by 2015, and 10 million tonnes by 2020.

India is considered to be the fifth largest producer of aluminium in the world with a tremendous bauxite reserve of about 3 billion tonnes. While the major consumption of aluminium in India is done by the electrical (31%) and B&C sectors (13%), the future growth is envisaged to happen in the solar power and industrial sector. One is witnessing the rapid development of this industry with a phenomenal growth noticed since 2002 and the industry is posed to play a significant role in the future growth of the Indian economy.

The aluminium extrusion process involves creating parts of homogeneous cross-sections which is achieved by forcing the metal through an outlet (that is designed in the required configuration/shape of the extruded profile) under high pressure. In an era when architects are increasingly coming forward with experimentations, aluminium extrusions are giving way to some imaginative and exquisite architectural designs which have been made simpler by the plethora of technological innovations and advancement in the aluminium extrusion industry.

Aluminium Extrusions - The Pros And Cons

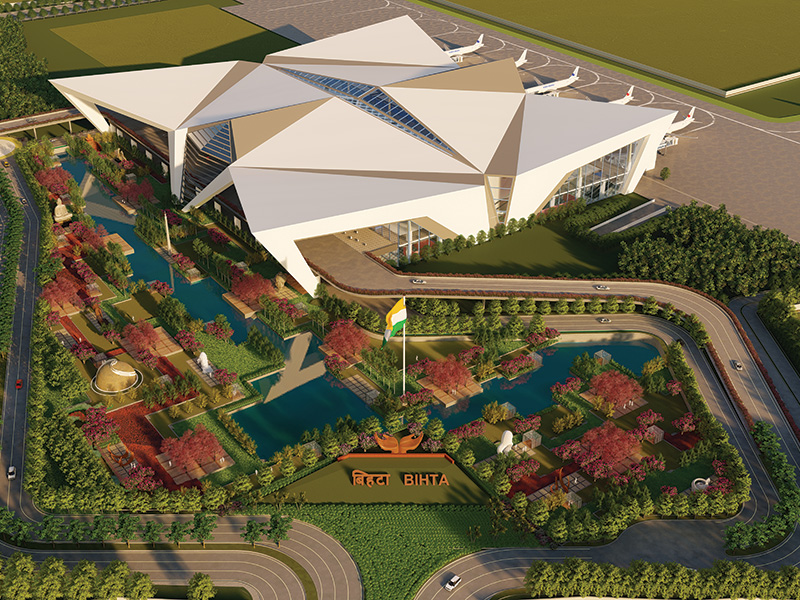

India's per capital consumption of aluminium extrusion is amongst the lowest in the world. The B&C industry which is the major consumer of aluminium extrusions in India (followed by the industrial and the transport segment) uses aluminium extrusions in prefabricated structures, windows and door frames systems, curtain walling, roofing and exterior cladding, space frame systems, geodesic domes, canopies, bridge decks, atriums, arches, etc. The popularity of aluminium formwork and shutters is also on the mount as it augments construction speed. There exists today an assortment of aluminium extrusion profiles in the market which are fabricated and are customised according to the specific requirements.

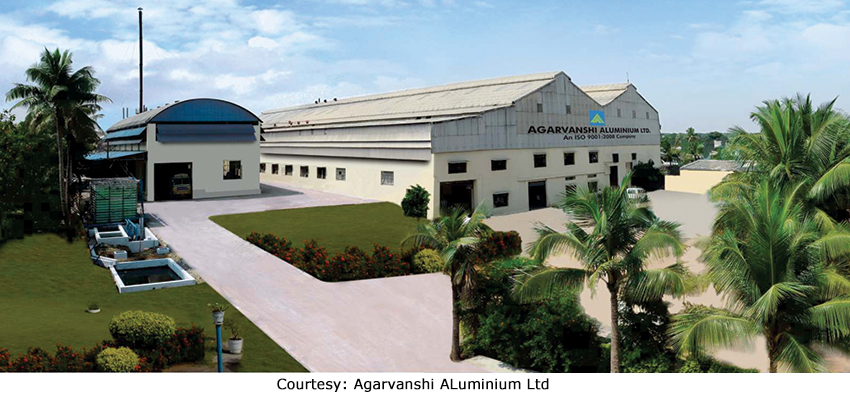

Mr Kapil Dwivedi, DGM Marketing of Secunderabad based Agarvanshi Aluminium Ltd (manufacturer of aluminium extrusions) says, "In architecture, aluminium extrusions are basically used for facades and windows. We at Agavanshi Aluminium Ltd meet fabricators, facade consultants and architects to discuss about our products but ultimately in India, there are various heads/authorities which decide which products and designs will perform. Here, I must add that the fabricators play a major role in this decision. They even suggest their own systems. Some facade consultants also give their own designs and we try and do our best to deliver them."

The huge demand of extruded products in the construction sectors has also been amplified with the number of metros being launched in different cities and the recent emphasis of the Government on low cost housing projects. Aluminium extrusions score due to their energy efficiency, non-corrosive nature, supreme finishes, functionality and space utility. The metal's lightweight and low density (1/3rd of copper or steel) whilst being one of the strongest construction materials, eliminates the need of addition of any extra weight to the building. Buildings in highly seismic zones also benefit from this reduced weight of aluminium extrusions (since seismic forces are proportional to the structure weight). The common use of aluminium extrusions in the design of impact and blast resistant doors and windows has also been noticed. Other factors include aluminium's ready availability, its versatility in getting extruded in various shapes and its durability which is much longer as compared to other materials like steel. The feasibility of more complex shapes, wider sections and tighter tolerances are making the extrusions more popular and a noted shift has been found in the attitude of the buyers who are focussing towards 'solutions' rather than just picking up 'off-the-shelf profiles'. Aluminium extrusions are also receptive to high-performance architectural coatings which help in maintenance-free performance.

In an environment where green buildings are talk of the day, aluminium extrusions are present for a number of green solutions in buildings. This include those for Double skin curtain walling, Photo Voltaic integrated systems, thermal breaks, sun light louvers and unitized solutions.

However, there are also a number of disadvantages of the Indian aluminium extrusion industry amongst which cost remains a major issue. High operational costs (rendering the profits on the lower side), higher administrative expenses per unit of manufacturing and sale of finished products (due to the sufficient staff that needs to be employed) are a hindrance. Many agree that though quality extrusions might cost more, but they come to an advantage in the longer run since the life costs become reasonable. Mr Dwivedi explaining his company's take on the same adds, "There is no choice other than aluminium extrusions for facades, though incase of windows we do have other choices too. We are trying to educate our fabricators and are approaching clients and trying to make them aware that aluminium might look expensive but it does always have an edge over uPVC."

One of the major uses of secondary aluminium (recycled aluminium) happens in extrusion in which case the primary metal is either imported (and processed by the secondary extruders at their own fabrication plants) or acquired through domestic producers. Since most of the domestic production is exported or is for captive consumption, the secondary players depend heavily on imported aluminium which again due to high import duties is expensive.

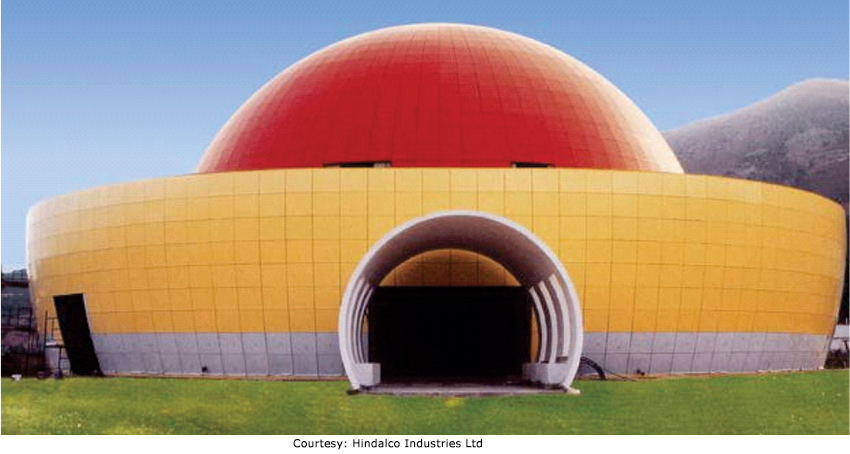

Technically too, the industry is witnessing some drawbacks. The smaller size of extrusion that can be manufactured technically (weight per meter and length) is an impediment where heavy, longer and big sized extrusions are required. In this regard, Hindalco will be adding a 5000 tons pressure extrusions press with 13.5 inches container size (by July 2013), thereby enabling bigger width & complex profiles in the country.

Also though the total capacity for aluminium extrusions in India is about 4,00,000 tonnes the industry of aluminium extrusion is highly fragmented with over 60 manufacturers of aluminium extrusions.

The Players

Mumbai headquartered Hindalco, the flagship unit of Aditya Birla Group making up a market share of 14% in the extrusions market offers aluminium extruded profiles used for a wide range of architectural applications like Windows, Doors, Hardwares, Curtain Wallings/Structural Glazing, False Ceiling, Exhibition Display, Furniture/Modular Systems, Hand Railings/Stairs/Balusters, Wall Facings, Louvers & Sun Screens, Rolling Shutters etc. Mr A. Jayagopal chips in, "Hindalco also does a lot of product development, which means using the right alloy and design for the profiles, shapes etc. We do a lot of application development like our roof-on-roof structural concept which is very popular in Kerala. We have installed aluminium roofing structure in around 150 projects."Madhya Pradesh based Maan Aluminium Ltd, established in 1989 has been supplying aluminium profiles to a very large number of high product specific demanding OEM customers whose requirements are typical in terms of alloy compositions, heat treatment and tolerances on dimensions which could be as stringent as DIN (Deutsches Institut für Normung e.V.) specifications. The firm is the recipient of the Export Excellence Awards by the Government of India and Mr Sunil K Shandilya, Executive Director of the firm remarks, "At Maan Aluminium Ltd, the efforts for quick delivery of material is augmented with the help of in-house tooling facilities which is complete with CNC Wire Cut and Milling, EDM, and complete heat treatment equipment. In order to provide support to end users and fabricators, two anodizing plants have been established within the premises where material can be supplied with anodic coating of 3 to 25 microns with cold sealing. The company offers silver matt and all intermittent shades between light bronze to deep black."

Vadodara based Banco Aluminium Limited, a leading aluminium extrusions manufacturing company manufactures standard and custom made aluminium extrusions for architecture, road transport, electricals, electronics, textiles, machinery, pneumatics, modular offices, kitchen furniture, automotive, heat transfer, hardware and many other applications where the versatile properties of aluminium have made it the preferred choice over other materials. The company has in-house capability to design and manufacture dyes for complex aluminium profiles.

Agarvanshi Aluminium Ltd has developed an aluminium casement (Agavanshi AC50) and sliding system (Agarvanshi AS50) for windows and doors and thus has become the first Indian extruders to have developed a complete system. This system has been tested and certified by experts from Italy. It has been developed as per ASTM and EN Standards and is also compatible with Euro Groove Type 1 profile which gives wide range of hardware choices.

Chennai based KMC Aluminium Pvt Ltd is a leading manufacturer of aluminium extruded products. It offers aluminium extrusions for a wide spectrum of industries including architecture, transport, industrial, electrical and consumer durables. KMC supplies aluminium extrusions all over India with its three presses of different capacities of 1400 tons, 900 tons and 600 tons. Its installed production capacity is 8,400 MT per annum. The firm also customises aluminium extrusions.

The Future

Making the industry less fragmented, getting involved in the fabrication of the extrusion with the customers at the design stage itself are few ways in which the extrusion industry can be enhanced. Schueco India Solar & Windows Pvt Ltd also points out that the knowledge of users and/or operators of buildings (operational competence), is of increasing significance. They are of the belief that most innovative building concept will inadvertently fail if it only performs in theory. During the building design phase, the firm also thus collaborates through its Architectural advisory and design team for optimal system solutions for the building envelope.Spreading Awareness

The Aluminium Extruders Council (AEC), based in US is an international association dedicated to helping manufacturers, engineers, architects, and others to discover why aluminium extrusion is 'the preferred material process for better products'. As part of the Council's ongoing mission to raise awareness and understanding of aluminium extrusion as a sustainable, practical, cost-effective solution to design challenges, the council released a new online learning educational course in August 2012 for architects, designers, engineers, building developers, and professionals on Aluminium extrusions. The course has been approved for continuing education units (CEU) by the American Institute of Architects (AIA), the USGBC's Green Building Certification Institute (GBCI) and more than ten other construction-based organizations.The Zak Aluminium Extrusions Expo has earned its name in the industry as the only trade fair in the world to be devoted entirely to Aluminium Extrusions, its technologies, applications and products. Catch the fifth edition of the same - the 2013 expo from 12th-15h December 2013, in Mumbai.