What's the common link between the gossamer woven spider's web, a circus tent, the sleek bus shelter and graceful lines of the luxury hotel sit-out areas? Engineering feats, architectural design or just plain creativity? It is really all of these. Explore the fresh construction options offered by tensile architecture and structures, invites Varsha Trehan.

The wonder of the structures at the Beijing Olympics venues was a revelation to the scope of possibilities utilizing tensile structures in the construction world. Closer home the stadia put up for the Commonwealth Games and various cricket venues incorporated these structures to keep the spectators comfortable. The concept is not new but the technology, material, and design innovations definitely are.

"Tensile membrane structures are complementary to conventional methods of construction, and can be easily combined with steel, aluminum, wood, concrete, etc. Being lightweight, it can be easily integrated into your existing structural details, and are aesthetically also quite appealing, due to the possibility of flowing and dynamic forms," explains Mr Ravi Mehta, Director, Sujan Impex.

"Fabric materials in modern architecture can shape space, enabling architects to sculpt 3D areas in a manner not possible by any other material. This kind of architecture is offering much more in terms of using natural light. The dynamic shape and form of membranes allow new possibilities to become reality," says Mr Faraz Aqil, National Sales Manager, Mehler Texnologies.

The seamless blend

Age no bar

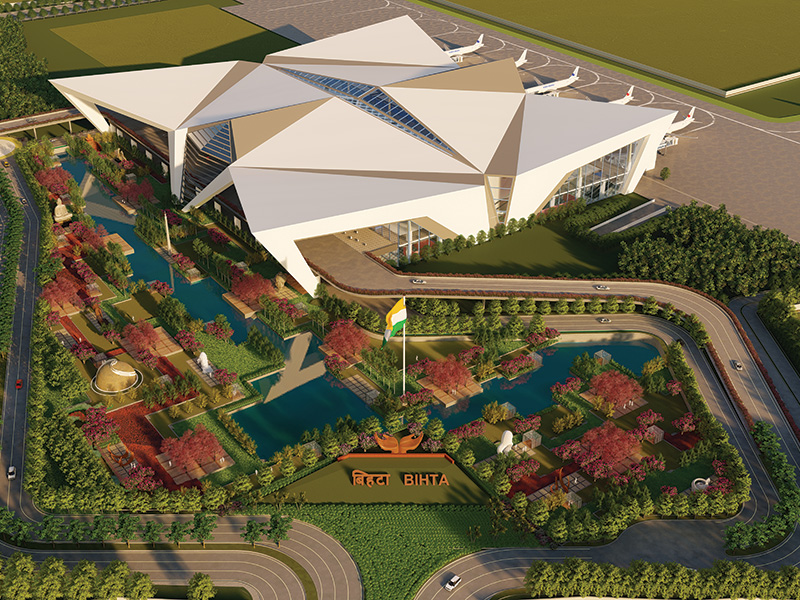

Is it a renovation or extension project that you are working on? Tensile structures are making their light footed inroads in this segment too. "Conventional methods of covering a large space like roofs, canopies, polycarbonate structures, cement sheets, etc. are being increasingly replaced by Tensile Structures worldwide. Entire roofs of buildings are being done away with and replaced by these structures, like in the case of many airports, stadia and malls around the world," informs Mr Obaid ur Rehman.

Continuing on the green advantage of tensile structure, Mr Augustine feels that this is good time to consider replacing materials like tarpaulins, plastic sheeting and asbestos roofing in storage and transportation solutions. "The fabric is long lasting which give strength to the life of the structure. Further, since the fabrics are asbestos free, it helps Mother Nature. The product being completely recyclable is an additional advantage" he opines.

The making of a tensile structure

For the uninitiated, it is important to understand that making of a tensile structure is a highly skilled job. A good vendor will offer the complete service package from concept to execution. "The process of manufacturing a tensile membrane structure involves design & analysis of steel membranes and fabric membrane; Design and detailing of clamping system; Fabrication of membrane, accessories & steel components and then comes the final project execution on site" clarifies Mr Prabhu Patil. He adds "Today membrane structures are replacing many conventional roofing materials, as these structures are available with many positive aspects. There should be separate subject at Universities on tensile architecture, which will surely bring this science to bigger platform." Taking the point further, Mr Ravi Mehta stresses, "Design & Engineering of Tensile structures is a discipline by itself, and the structural elements mostly used are steel and the membranes, apart from concrete for the foundations. The major point that differentiates Tensile structures from other cladded structures is that the roofing material is also part of the structural design, and takes structural loads, unlike rigid materials like glass/polycarbonate etc. which are used for cladding, and do not carry any structural loads. Since the material is flexible, the behavior of the same under dynamic live loads is very important, and the same have to be factored in while engineering." The structural analysis must be completely integrated into the architectural design as "the geometry of the membrane is established through a form finding technique in order to ensure static equilibrium of the system," explains Mr Aqil.Elaborating on the need for technical competency, Mr Hasubhai Gajjar says, "All our designs are a product of customized resolved geometry with optimum use of material with efficient fabrication and installation. We use a combination of modular design, space frame construction and tensile membrane structures." Supporting the need for technical competency Mr Obaid enunciates "Combining expert design skills and on-site knowledge enables us to provide efficient and economical solutions for all Tensile Membrane Structures. The process of cutting and welding all the fabric panels together is carried out by our experienced team. Our specific and detailed instructions enable them to deliver top quality fabrications. The structure is made by our specialist steelwork team. Our dedicated product advisors and installers will help you make the right decision and ensure that what you need is perfectly incorporated into your home and business environment."

The structural elements

A tensile structure comes together through two types of structural elements -- the tensile and the compression members. These form the basic support system. "The major categories of structural elements used are the M. S. Steel, SS steel, GI or SS fabric plates, GI or SS wireropes, wall bracket and concrete and the standards applicable are the Indian or the British standards ASTM" explains Mr Augustine. In different words, Mr Dake names the elements as "Membrane, tensile cable, masts, compression rings or beams and foundations." The make, thickness, surface coating of the membrane fabric are as important as the cut of the panels in direction of the fabric. "A coated structural fabric usually consists of a woven base cloth stabilized and protected by coating on both sides. The base cloth consists of warp threads running the length of the roll and weft threads running across the width. For engineering of tension structures, the most common choices are PVC coated Polyester cloth materials. These generally have a structural lifespan in excess of 20 years. The PVC coating contains additives that include UV stabilizers, fire retardants, coloring and fungicidal agents," clarifies Mr Faraz Aqil.All these 'light' elements emerge from the cauldron of engineering technology to span over the required structural form while resisting deformation, efficiently and safely.

The caring customer

Tensile architecture is on the growth path, which does not mean that the form is well established in the domestic market. A customer looking for best value for money needs to take care to choose a reputed agency for the tensile structure design. "Clients need to give comprehensive brief and to be selective to choose vendors with diverse and responsive portfolio" feels Mr Dake. The vendor should then be in a position to offer advice on the after care and repairs besides the initial counseling on design, structural work, quality and thickness of the membrane to be used. Keeping direction Mr Augustine cautions "My advice is, avoid cheap products and non-standard vendors. If the work is not carried out professionally, you intend to pay more on repairs and maintenance later. Keeping a maintenance schedule for the structure is vital." Mr Patil seconds the value of upkeep "Customers should be aware of that these beautiful structures need some attention to increase durability and preserve their aesthetic value." According to Mr Aqil, it is as simple as say regular hosing down or effective ventilation in areas of high humidity to prevent mould growth and staining. He advocates addressing minor problems at the earliest as they can become major if neglected.Talking about the Precontraint Technology from Ferrari Mr Mehta explains "Fabrics are an unforgiving material. It does not tolerate shoddy or improper design/engineering or installation. Even after allowing for stress compensation, there is a strong possibility that the membrane under live dynamic loads will tend to have more residual elongation than a precontraint fabric. This residual elongation will necessitate periodic re-tensioning of structures, which in India is never done, once the structures are installed. If the fabric develops a slag and is not re-tensioned, it will start flapping under windy conditions, and the fabric will lose the strength due to constant flapping, and thus the life of the fabric will be reduced."

The customer is therefore well advised to check out the vendor's track record and keep up with regular post installation checks.

In support of tensile membrane roofing

Tensile structures are a building technology that uses flexible materials and holds up the structure using tension forces, rather than weight as in brick mortar construction that comprise compression structures. Major advantages seen in adopting tensile membrane architecture include:- Design possibilities are limited only by skill and imagination. There is enormous scope to create unique forms within budget constraints. This is a winning point over materials like concrete, glass or polycarbonate.

- Membrane translucency means natural light is fully available to enhance indoor ambience and save on artificial lighting expenses.

- The special coatings on the membrane filter UV rays from the sun and act as heat retardant insulation too. Power bills for HVAC substantially reduce with this.

- Tensile structures include welded panels, single or multiple as per design. This works for very efficient waterproofing over other materials which require additional fittings and sealants.

- Panels are factory fabricated and installed onsite. This means clean sites, lesser time to completion with minimum disruption.

- Most of the materials are recyclable. The deadload of material is reduced considerably as material strength is utilized to its fullest resulting in optimal utility.

Value for money

Addressing durability concerns, Mr Obaid says, "Tensile structures are very sturdy and can withstand all types of weather conditions. The fabric can withstand temperature up to 70 degrees and - 30 degrees Celsius. They are suitable for indoor as well as outdoor applications. The average life of Tensile Structures can be 20 to 40 years depending on the structural work and thickness of fabric used."In certain locations like chemical industries, Mr Gajjar feels that tensile membrane structures may not be a right choice. He would also prefer that in the Indian context, this option be exercised more in secondary structures like semi open spaces, screen wall, gazebos rather than for primary structures. Mr Dake's take is that some parameters need to be met before advising tensile structure construction for any project. Therefore, reliable consultation is important.

With the benefits offered this construction element, has a strong case to be considered. And as Mr Patil puts it -"Tensile structures are aesthetic feathers added to wings of modern architectural science" makes the possibilities worth exploring.