The Remarkable Growth Story of GALVALUME sheet steel continues

Arif Humayun, BIEC International Inc, USA

In the 1960s, two young Bethlehem Steel researchers, Jim Horton and Ange Borzillo, began a program to develop a hot-dip coated steel that married the barrier corrosion resistance of aluminized steels with the sacrificial protection of galvanized steel. They could never have envisaged how successful their development would become. The coated steel they invented, subsequently trade marked Galvalume®, had an alloy coating of 55% Al and 45% Zn1 (55% Al-Zn). The growth of GALVALUME sheet steel around the world has been remarkable and its cumulative global production through 2008 has exceeded the 100 million ton milestone. From its commercial introduction in 1972, the first million-ton milestone was reached in 1979 when the only producers were Bethlehem Steel in the USA and John Lysaght (now BlueScope Steel) in Australia. The subsequent increase in the number of licensed producers has resulted in the rapid toppling of significant production milestones: over 5 million tons in 1985, 24 million in 1994 and just over 43 million tons at the end of the century. Through 2007, approximately 93 million tons have been produced.

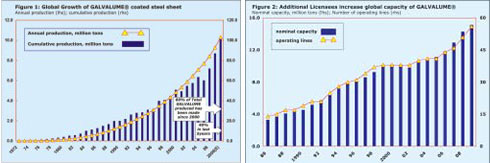

The acceleration in production since the turn of the century is highlighted in Figure 1. Fully 60% of the 55% Al-Zn coated steel sheet ever made has now been produced since 2000; 40% during the last 5 years. This remarkable growth demonstrates the product's strong and accelerating customer acceptance as the material of choice for the construction market.

Current global production now exceeds 10 million tons/year. To help put this figure into perspective, the annual production of 55% Al-Zn coated sheet is equivalent to the annual production of all hot dip coated sheet steel in Japan, which is an extremely coated, product-intensive steel producing nation, primarily focused on coated steels for automotive applications. And, since the vast majority of 55% Al-Zn product is produced in lighter gauges (0.2 to 0.6 mm thick) compared to other hot-dip coated products, on an area basis, the percentage of 55% Al-Zn production is even greater. This production growth confirms that the product has not yet matured.

Growth will continue

A very impressive compound annual growth rate (CAGR) has been maintained for 55% Al-Zn coated steel sheet over the last 25 years. The approximate 10% CAGR achieved so far this century is expected - based on licenses already signed and those in the pipeline - to accelerate to levels approaching 12% in the remaining years of this decade when the annual production is expected to reach 14 million tons. This represents almost 10% of all hot-dip coated steels produced throughout the world, and that includes China. We expect this growth rate to continue for the foreseeable future because newly licensed lines are scheduled to commence production and the production ratio of 55% Al-Zn coated steels on multi-purpose lines will increase.

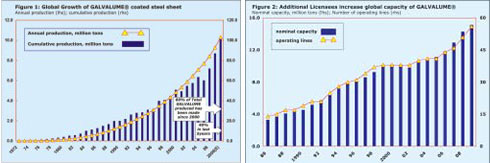

The number of lines that have been licensed and are producing 55% Al-Zn coated steels is illustrated in Figure 2. In 2008, fifty-six licensed lines are now in production. Currently, BIEC2 has licensed 60 companies to produce 55% Al-Zn coated sheet and some licensees operate multiple lines. It is entirely conceivable that the number of operational lines could exceed 60 by the end of the decade. Interestingly, 65% of the producing lines are now located in Pacific Rim countries - a region that has seen, and will continue to see, tremendous growth. By the end of the decade, a total of 9 new lines will be operational in India, three in Africa, and an additional line in Thailand. The Asian and Pacific Rim production alone is expected to exceed 10 million tons, which represents about 65% of the total global production of 55% Al-Zn coated sheet.

Most significantly, the doubling of production and the number of operational lines during the last decade occurred during the Asian financial crisis of the late 1990s. This period witnessed the advent of Low Coating thickness (Mass) (LCM) 55% Al-Zn coated steels for traditional construction applications. LCM features thinner coatings than the premium 150 g/m2product and are used to directly compete with thinner galvanized steels. Of course, the main driving force for the specification of LCM has been reduced cost but the thinner, high performance 55%Al-Zn coated steels have maintained their superior corrosion resistance advantage over thin hot-dip coatings. This change in product mix is increasingly important because it enables 55% Al-Zn coated steels to compete with much lower cost products and ensures that the growth of 55%Al-Zn coated steels will continue. The Zinc Aluminum Coaters (ZAC) Association, a worldwide trade association of licensed producers, is assessing the durability of these high performance thinner coatings in a global collaborative program.

Licensed versus Unlicensed Production

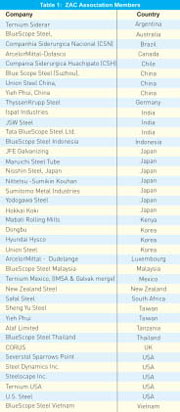

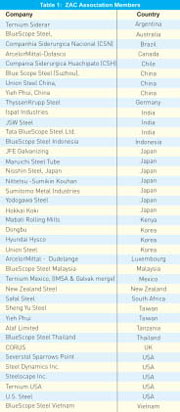

Recently, a number of unlicensed producers of 55% Al-Zn coated steels have appeared - particularly in China - claiming, in many instances, that their products perform 'like Galvalume'. That may be accurate but these unlicensed producers do not have access to the most recent technology to produce their products. In contrast, licensed manufacturers can become members of the ZAC Association, a global users association that exists solely for members to share up-to-date intellectual property on manufacturing enhancements, product performance, product development and market development. Access to this information allows new licensees to rapidly become reliable producers of high quality 55%Al-Zn coated steels and for all licensees to rapidly overcome manufacturing and product problems because they can readily access the more than 500 years combined proprietary production experience of licensees. This enhances the ability of licensed producers to offer superior technical and product applications services to their customers. BIEC and its licensees consider the maintenance of product integrity as being critical for the further growth and acceptance of GALVALUME sheet. The ZAC Association has, therefore, initiated new 'immersion learning' initiatives to ensure that all licensees maintain access to, and utilize, the latest technological innovations to further differentiate them from unlicensed producers. Users of 55% Al-Zn coated sheets can then be confident that products produced by licensed producers have the 'mark-of-excellence'. The list of current ZAC Association members is shown in Table 1.