Increasing demand for stainless steel has been witnessed from users across construction, transport and several industrial sectors, and steel use is set to grow by leaps and bounds in India, reports Bhaswati Das.

Stainless Steel is an established material in international design. It's contemporary, stylish yet its neutral look is gaining immense popularity among all kinds of users and tops as a material of choice for its excellent blending ability with any other material, viz. glass, ceramics, wood or leather. The material has been providing great opportunities and inspiration to generations of designers. Today its use is being taken to new levels of expression and technical sophistication.

Stainless Steel in Buildings- Underlying Reasons

Another major reason for the success of stainless steel is the fact that they are among the most durable building materials ever invented. Because of their self-repairing characteristics, properly selected and fabricated stainless steels constructions will last for a lifetime. Even where environments are more aggressive, such as in heavily polluted areas and close to the sea, properly selected stainless steels will remain untouched.

Today, stainless steels are used more than the roofing and facades for which they were first applied back in the 1920s. For example, because of their hygienic characteristics they have become standard for handrails. Moreover, stainless steels have found their way into structural applications owing to their excellent corrosion and fire-resistant characteristics.

Issues that might very well make stainless steels the preferred material of construction for the 21st century area include life cycle costing and sustainability. Although initial design costs might in some cases be higher, stainless steels do not require painting, cleaning, and the savings on maintenance generally more than compensate for the initial higher investment. After its use the stainless steels are 100% recyclable, and there are no limits to the amount of recyclable scrap that can be used to produce new stainless steels, significantly reducing the environmental impact.

Designer Guidelines

Besides for aesthetic reasons, stainless steels are often used for their structural properties. Strength and fire resistance make them very suitable for all kinds of structural applications such as roofing. Besides that, life cycle cost considerations such as low maintenance and the inherent long lifetime play an important role. Stainless steels are also lighter than most other metallic roofing materials, which can result in a lighter, more cost effective supporting structure.The designer must bear in mind that the structural behavior of stainless steels differ in some respects from that of construction steels and aluminium. The following are their most important properties.

Strength and Rigidity

Stainless steels are often stronger than ordinary construction steels, depending on type. In general, they are somewhat less rigid. As a rule, the dimensions of constructions using stainless steels are the same cladding for facades is to choose a sheet that is too thin. In these cases, the sheet, though strong, will not be rigid enough. The rigidity depends on the modulus of elasticity and the thickness of the sheet.Brittleness and Toughness

Stainless steels are tougher than construction steels at all temperatures (including low ones) and so are used, for example, as reinforcement in concrete structures for cryogenic installations such as storage tanks for fluidised gases.Fire Safety

In the event of fire, stainless steels are stronger than construction steels. Stainless steels are also used to increase resistance to the spread of fire. The oxide film that forms on the surface grows very slowly – in some types only at temperatures over 1150C – so that in the event of fire little or no peeling away of the oxide film occurs, and thus no reduction in thickness.Fatigue

Tests have shown that the resistance of stainless steels to fatigue is at least as good as that of construction steels. The calculation methods used by designers for construction steels can also be used for stainless steels.Stainless Steel in Construction

Austenitic stainless steel hollow sections are a superior construction material, particularly when structural strength is necessary together with corrosion resistance and aesthetically appealing finishes. Austenitic grades like AISI304 and AISI316 are the most popular standards, comprising about 70-80% of all stainless steel used. Their success is based on excellent corrosion resistance, good mechanical properties, combined with a relatively low cost.Normally, the austenitic grades EN.4301, EN1.4306, EN1.4541, EN1.4571, EN1.4318 are available in different product forms including hollow sections. Between those grades the mechanical strength and fire temperature properties vary to some degree. The duplex grades are also used in building and construction applications when high mechanical strength is needed in aggressive environments, like bridge structures.

Hollow Steel Sections in Construction

The advantages of stainless steel hollow sections for building and construction applications are high mechanical strength, high temperature resistance, corrosion resistance, aesthetic surfaces and easy maintenance. These are the considerations for choosing stainless steel for structural applications. The main application for hollow sections in the building branch are in façade structures made of glass, which are supported by hollow sections, balcony structures, storage shelters and of-course the columns and frames that form the entrances to office buildings and department stores.Words of Caution

Things to bear in mind while using stainless steel:- Detailed attention must be paid to the design otherwise corrosion may occur in areas where dirt and grime can collect.

- Rainwater that drains out of curtain walls clad in stainless steel needs to be controlled, otherwise staining will occur.

- The production process of stainless steel coils intended for cladding purposes needs to be controlled significantly different then from normal coils.

- Protect the work from contamination such as contact with dirty scaffolding, carbon steel grinding, concrete dust and splashing.

- Stainless steels are often more cost effective than other options.

Indian Scenario-Progressive Path

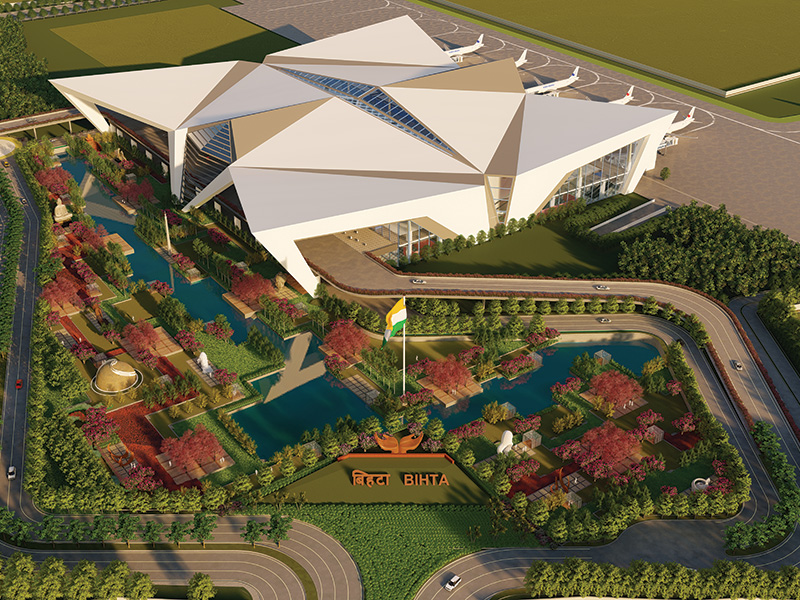

Though Indian consumption grew over last decade at 13-14 percent, stainless steel demand is expected to grow by 12 percent annually, opening immense avenues for multiple applications, especially in railways, airports, public utility infrastructure, municipal/urban local bodies, Commonwealth Games 2010, structures malls, hospitals, tourism & hotels, and construction sector.These apart, there are numerous novel opportunities for stainless steel usage in India, both within our existing infrastructure newer ones. This would go on to transform our civic and market dynamics, making India a global destination for international events such as the Commonwealth Games.

Nevertheless, stainless steels have become a well-established building material in the century since its invention thanks to their excellent characteristics. However, their full potential has definitely not been reached. Hence, stainless steels look set to push ahead in the architectural, building and construction market stronger then ever.